Bending head device of reinforced hoop bending machine

A steel bar bending hoop and bending technology, applied in the field of bending head, can solve the problems of wasting manpower and material resources, inconvenient processing, inconvenient assembly and disassembly, etc., and achieve the effect of saving manpower and material resources, convenient processing and maintenance, and simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention can be explained in more detail with reference to the following examples; however, it should be noted that the present invention is not limited to the following examples.

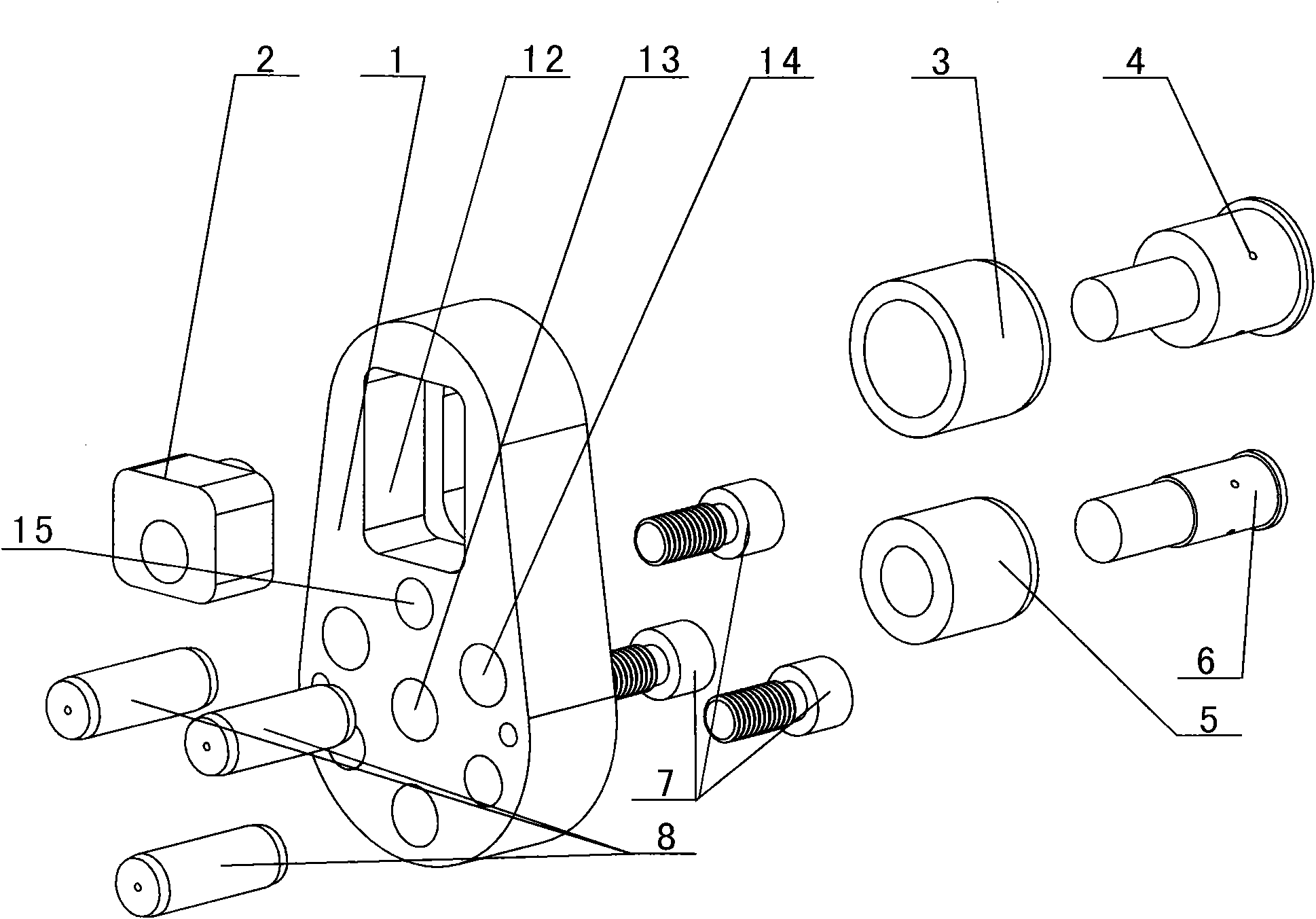

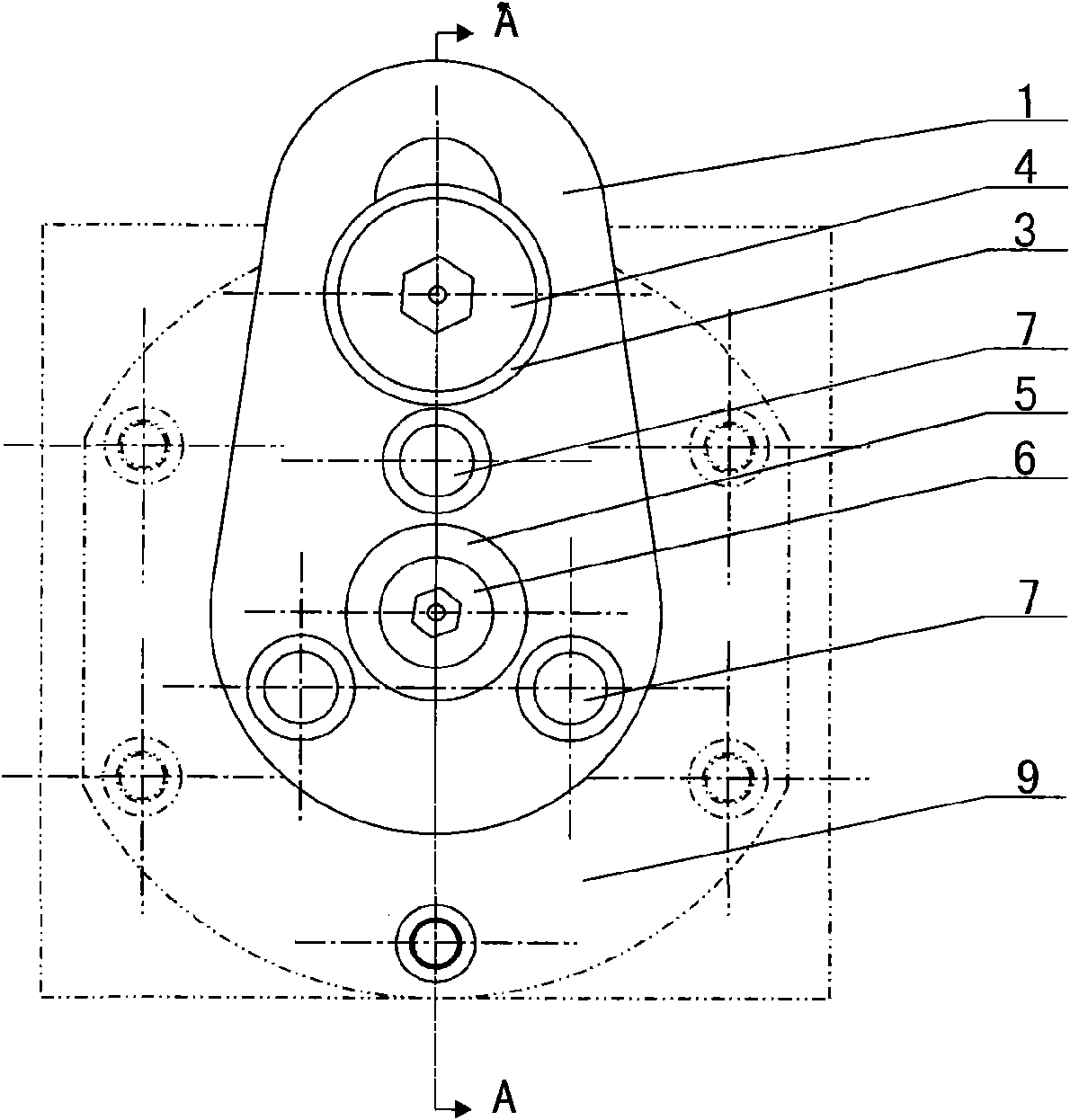

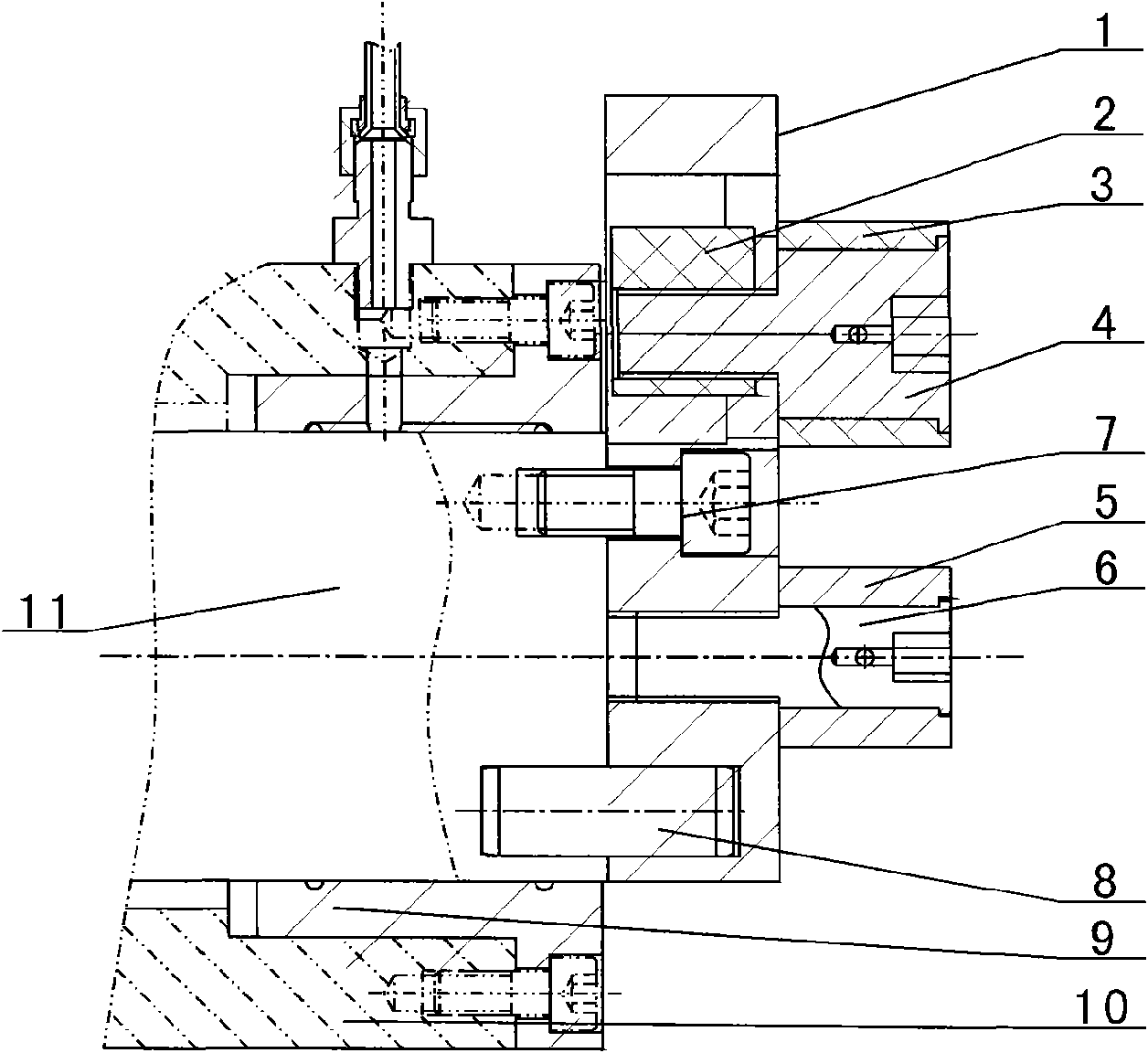

[0021] exist figure 1 , 2 . The bending head device of the steel bar hoop bending machine described in 3, the bending main shaft 11 is set in the bending seat 10 through the bending main shaft sleeve 9, and the lower part of the bending plate 1 is connected with the bending main shaft 11 through the bolt 7 and the connecting pin 8. The upper part of the curved plate 1 is provided with an adjustment block guide groove 12 on one side of the plate surface. The adjustment block 2 is in the adjustment block guide groove 12 through the bending shaft 4, and the adjustment block 2 slides up and down in the adjustment block guide groove 12. Cooperate to meet the bending needs of steel bars with different diameters; a mandrel perforation 13 is provided at the center of the lower part of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com