Separating type bending upper die plate assembly

A separate and template technology, which is applied in forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems of single applicable object, time-consuming replacement and repair, etc., and achieve the effects of high positioning accuracy, convenient replacement and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

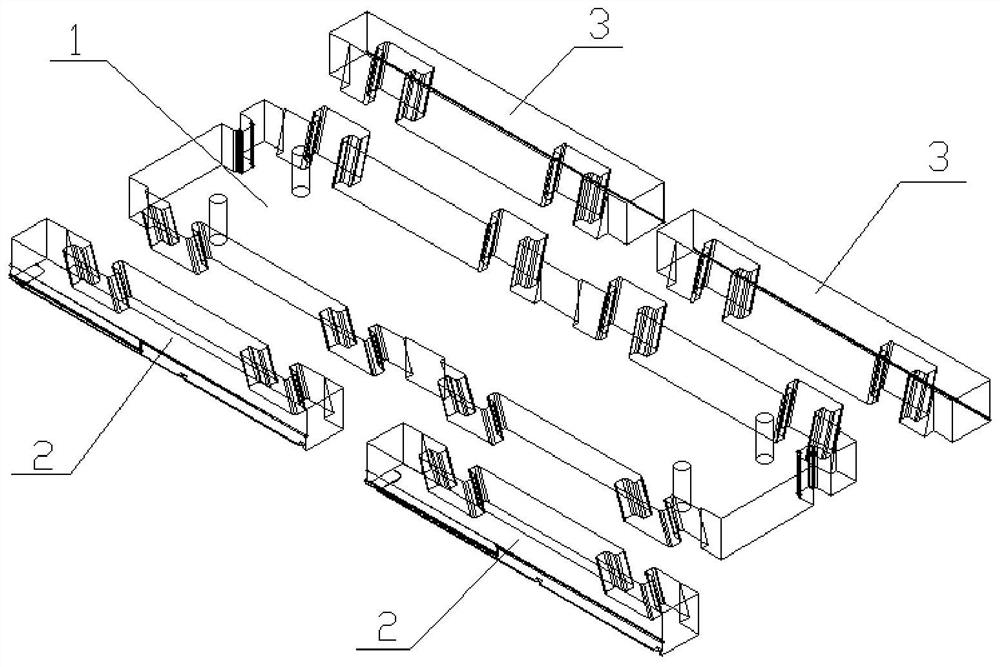

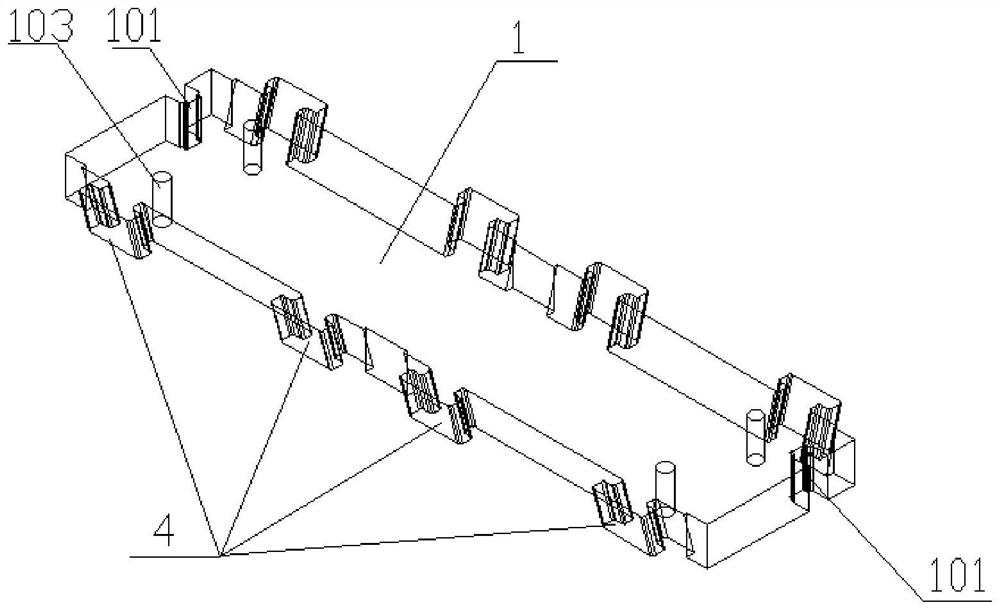

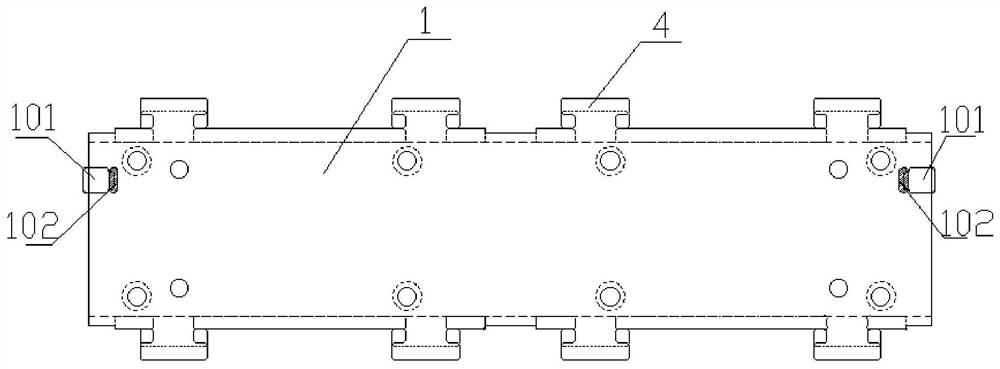

[0044] This embodiment provides a separate bending upper formwork assembly, including an upper formwork 1 , and the separate bending upper formwork assembly further includes a first bending connecting piece 2 and a second bending connecting piece 3 . The side is provided with a convex block 4, the protrusion end of the protrusion block 4 is connected to the upper template 1, and the first bending connector 2 and the second bending connector 3 are provided with fixed grooves that match the protrusion block 4. 5. The protruding block 4 is fitted with the fixing groove 5, so that the first bending connector 2 and the second bending connector 3 are respectively installed on both sides of the upper template 1;

[0045] A first bending angle 201 is formed on the side of the first bending connector 2 away from the fixing groove 5 , and a second bending angle 301 is formed on the side of the second bending connecting member 3 on the fixing groove 5 .

[0046] As a preferred embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com