A method of using the hydraulic system of a multi-cylinder linkage hydraulic press

A technology of hydraulic system and hydraulic press, applied in the field of hydraulic system of multi-cylinder linkage hydraulic press, can solve the problem that the hydraulic system cannot well satisfy the bending operation of hydraulic press, reduce vibration and noise, reduce the impact load of pipeline, and prevent overloading of work. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

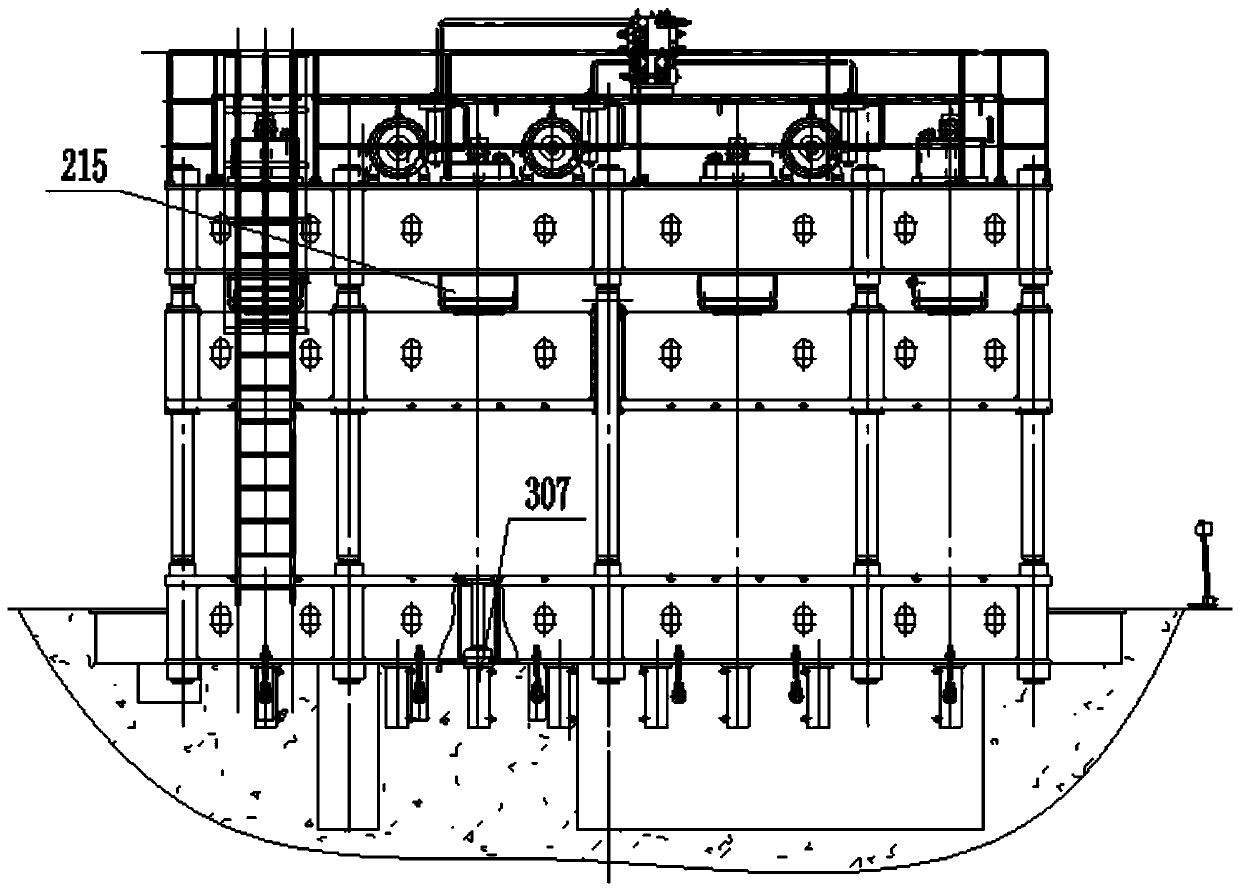

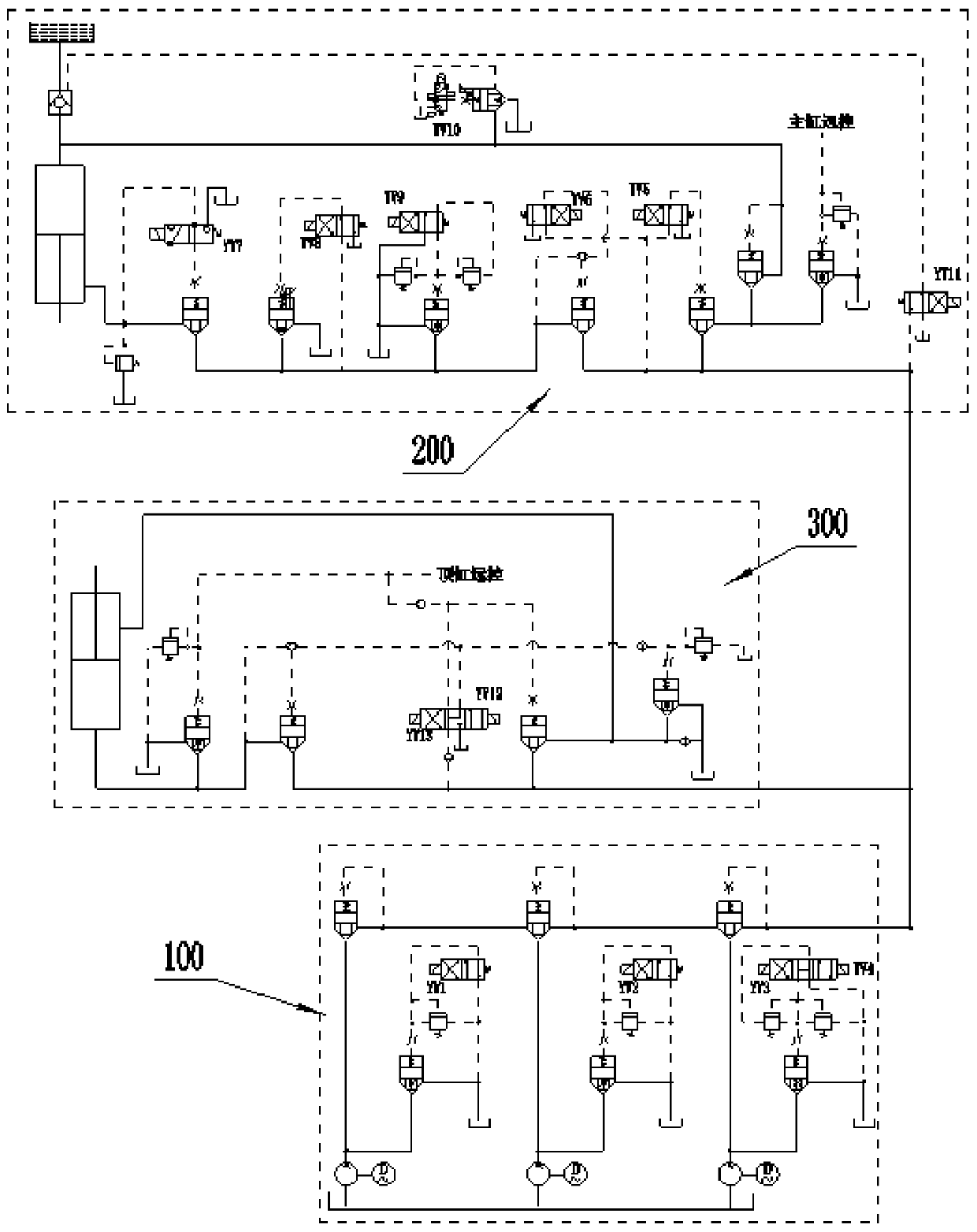

[0067] The hydraulic system of a multi-cylinder linkage hydraulic press in this embodiment is mainly used for the control of large hydraulic presses with a tonnage of more than 1,000 tons, that is, it is generally applicable to hydraulic presses with more than six columns. For example, the applicant previously applied for a utility model patent titled: A large-tonnage long-span multi-cylinder linkage automobile longitudinal beam pressing and forming hydraulic press, the application number is: 201720545948.4 utility model patent, its structure is as follows figure 1 As shown, there are 10 columns and the tonnage reaches 1650 tons. Such a huge hydraulic machine needs 4 main cylinders 215 to drive the slider to drive the upper mold to move up and down along the column to complete the bending of the workpiece in the lower mold fixed on the workbench. operation, its requirements on the hydraulic system are relatively high; and the hydraulic system structure on the existing general h...

Embodiment 2

[0086] A method for using the hydraulic system of a multi-cylinder linkage hydraulic machine in this embodiment, by controlling the pumps, valves and oil cylinders in the hydraulic system of Embodiment 1, the fast down, slow down, pressure relief and return actions of the main cylinder 215 are realized, as well as the jacking action. The ejection and retraction actions of the cylinder 307.

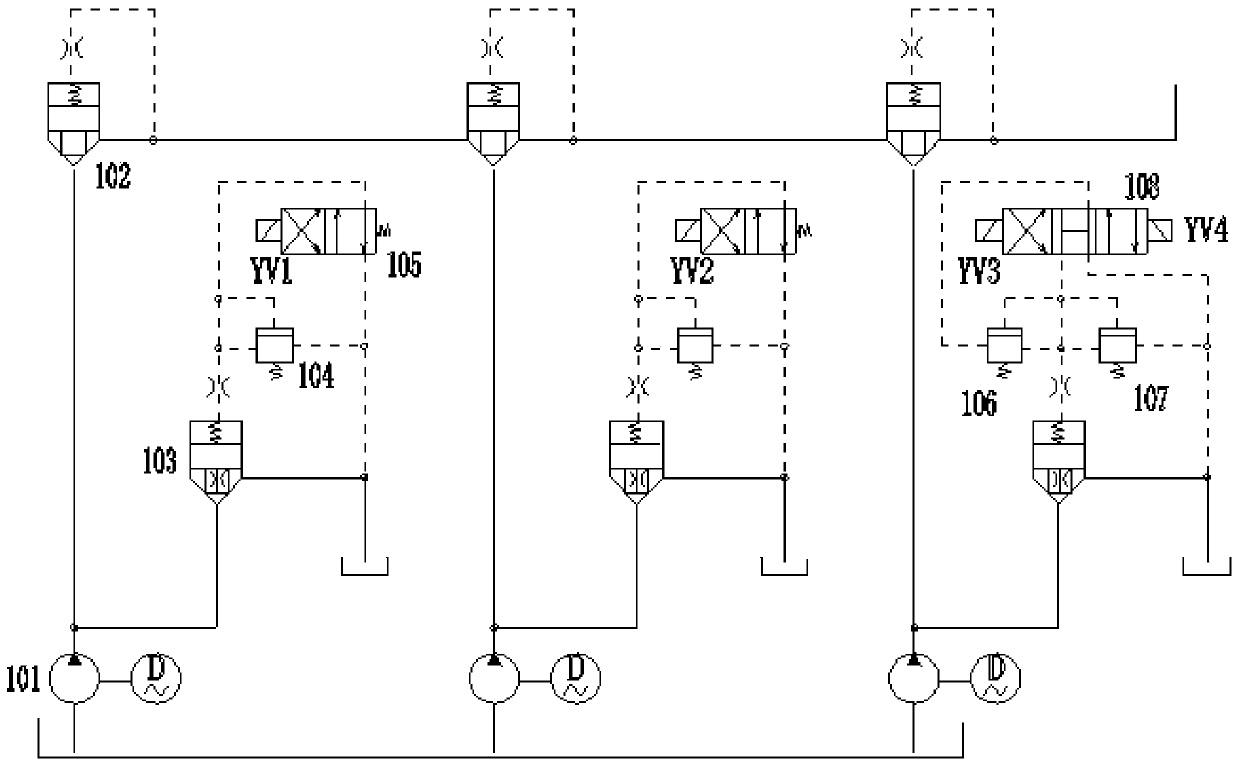

[0087]In this embodiment, the electromagnets of the two-position four-way solenoid valve I105 of the first two groups in the oil supply control part 100 are denoted as YV1 and YV2 respectively, and the electromagnets on the left and right sides of the three-position four-way solenoid valve I108 of the latter group are denoted as YV3 and YV4; two-position four-way solenoid valve II203, two-position four-way solenoid valve III205, two-position three-way solenoid valve I213, two-position four-way solenoid valve V211, two-position four-way solenoid valve IV209 in the main cylinder control part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com