A kind of rotary bending equipment and its processing method

A kind of equipment and technology to be processed, which is applied in the direction of metal processing equipment, manufacturing tools, storage devices, etc., can solve the problems of difficult to effectively guarantee the quality of parts, lack of accurate bending processing equipment, irregular manual bending operations, etc., to achieve guaranteed The effect of processing quality, simple structure and increasing the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Objects, advantages and features of the present invention will be illustrated and explained by the following non-limiting description of preferred embodiments. These embodiments are only typical examples of applying the technical solutions of the present invention, and all technical solutions formed by adopting equivalent replacements or equivalent transformations fall within the protection scope of the present invention.

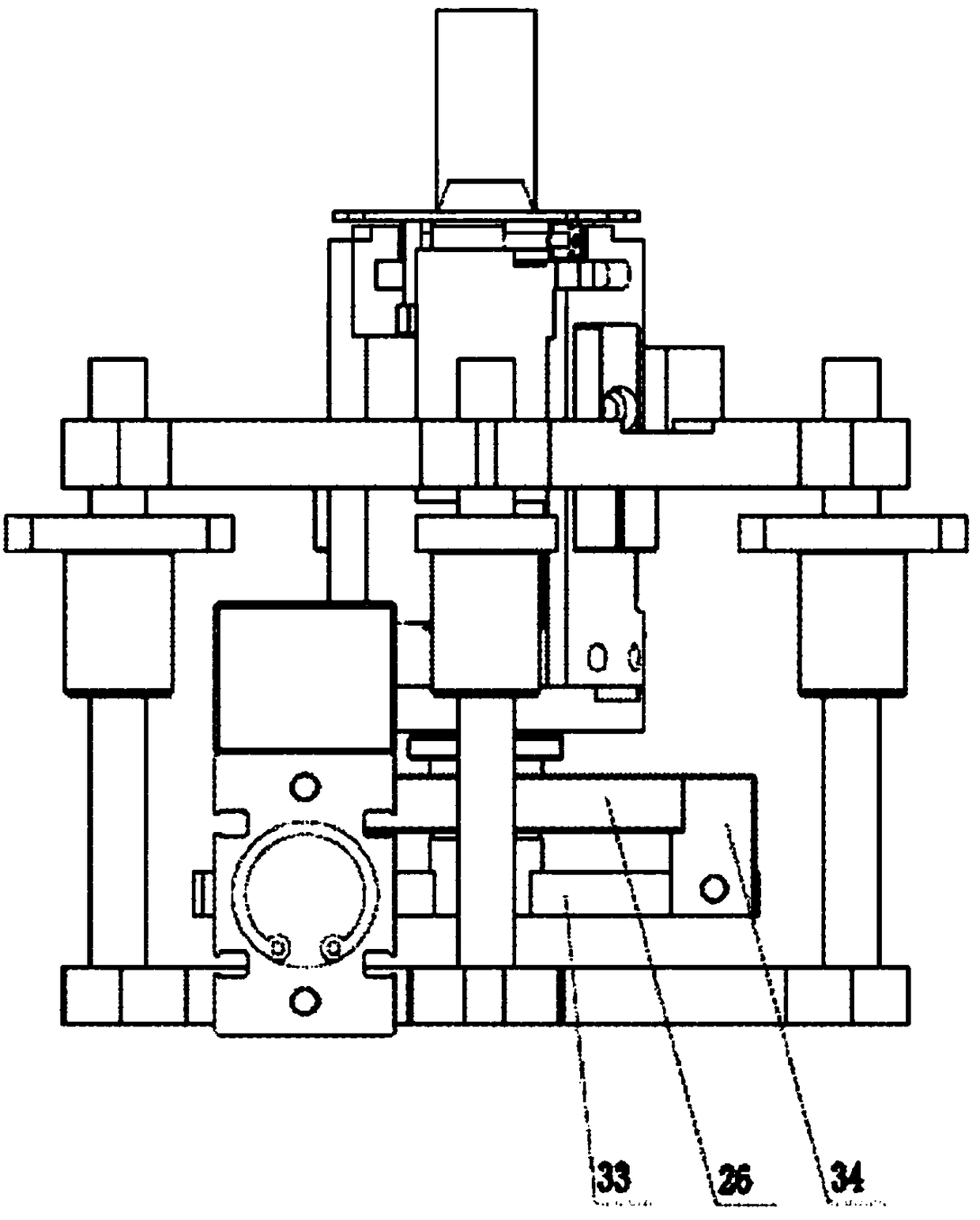

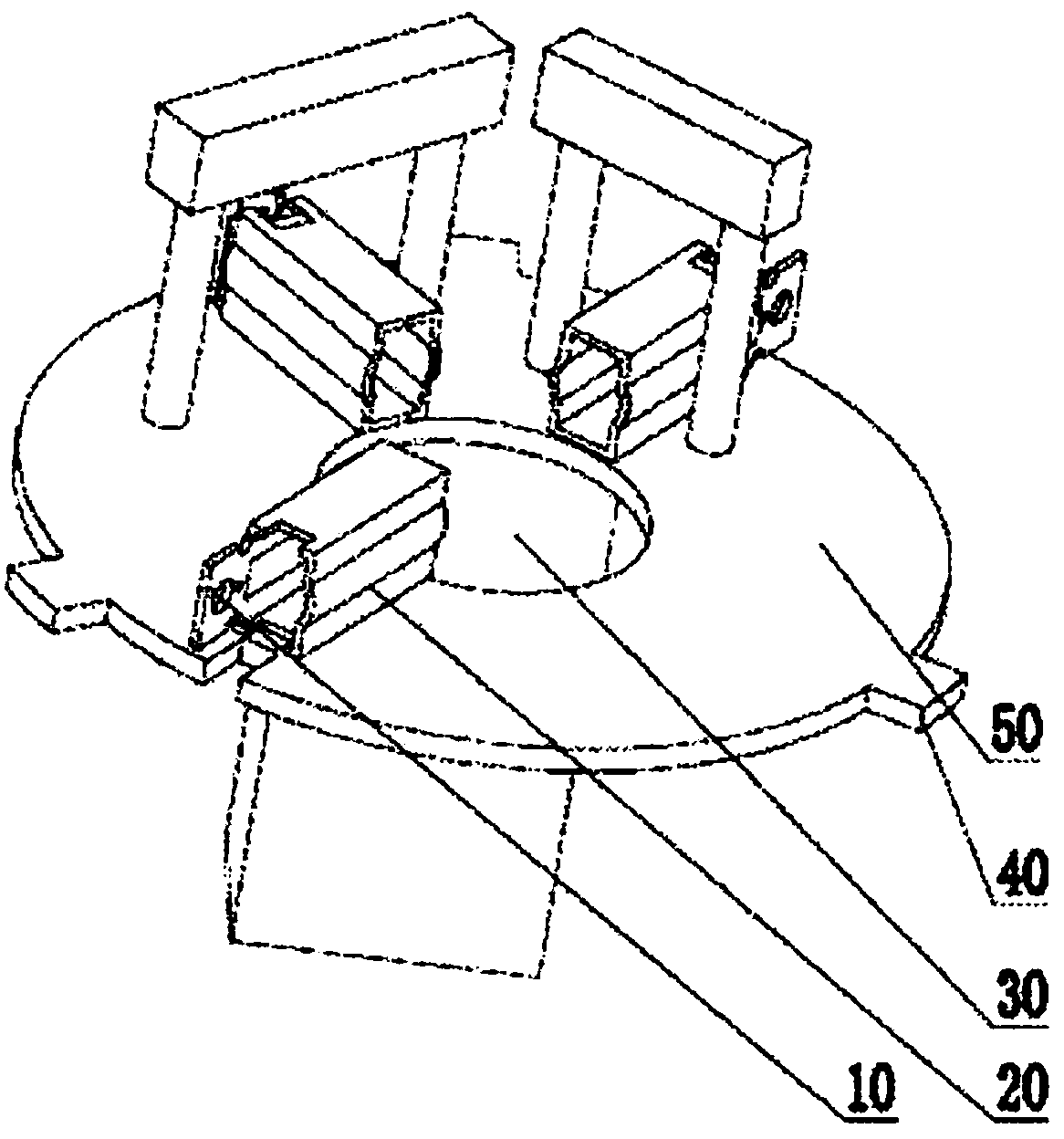

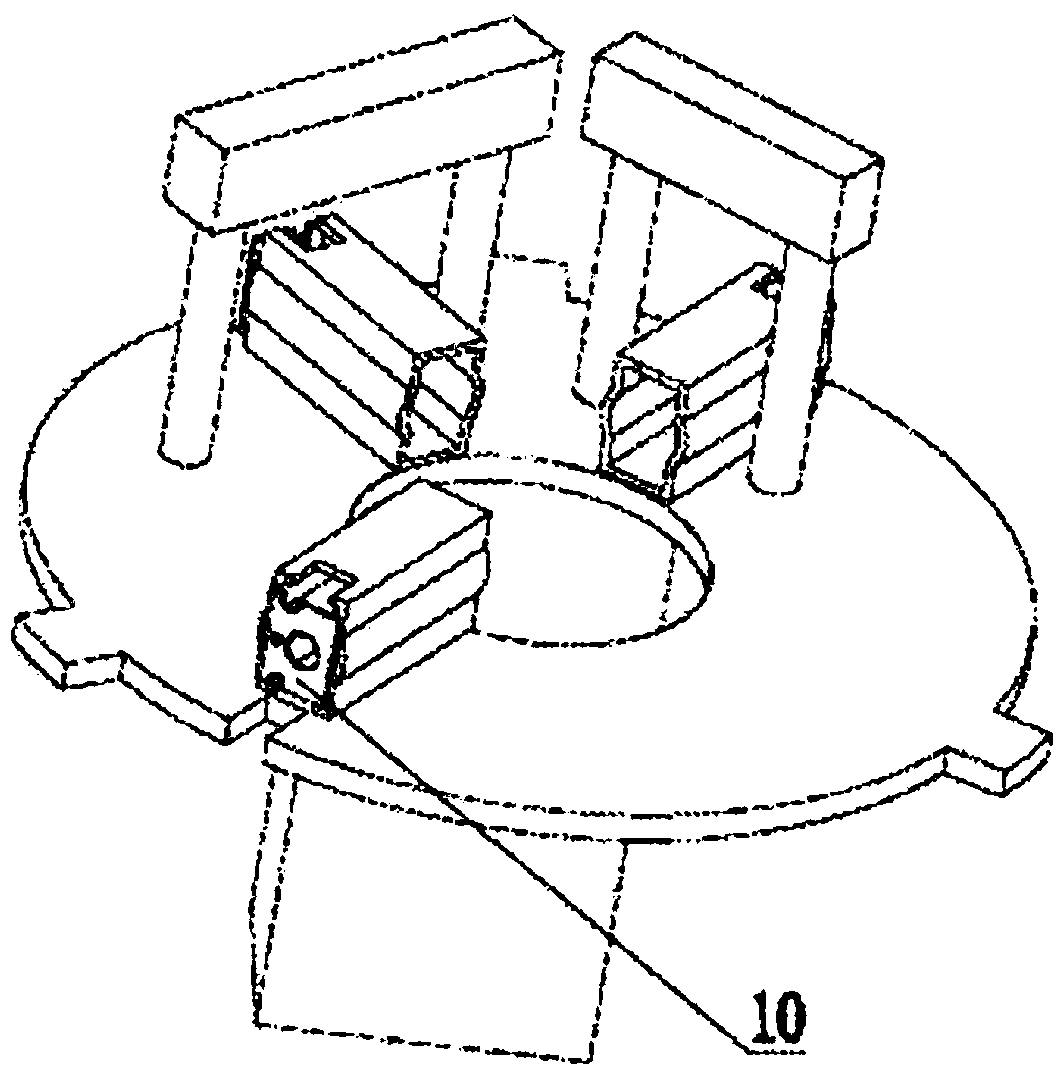

[0035] The flanging rotary bending equipment disclosed by the present invention, as attached image 3 shown, including

[0036] The product-to-be-processed fixing carrier 1 is used to fix the product to be processed;

[0037] The rotary bending mechanism 2 is used to bend the flange 10 of the product to be processed on the product carrier 1, and the rotary bending mechanism 2 is arranged coaxially with the fixed carrier 1 of the product to be processed;

[0038] The driving mechanism 3 is used to drive the rotary bending mechanism 2 to reciprocate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com