Hydraulic dynamic bending machine

A bending machine and hydraulic technology, applied in metal processing, metal processing equipment, forming tools, etc., can solve problems such as overrun, insufficient force, and impact on the quality of formed plates, so as to achieve precise control, quality assurance, and Even force and precise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below in conjunction with the accompanying drawings.

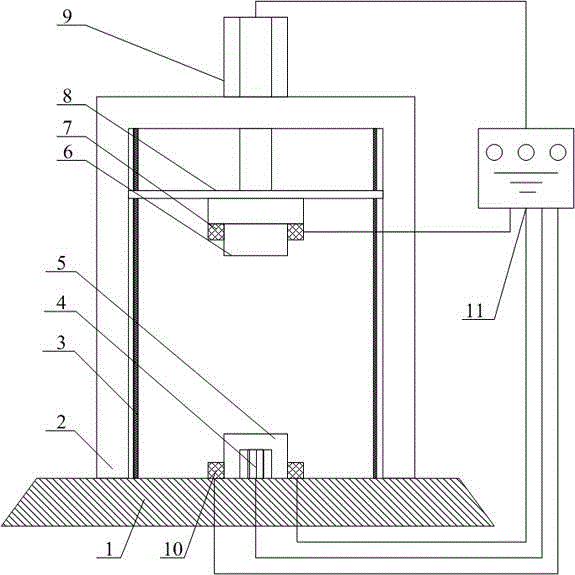

[0012] Such as figure 1 As shown, in the hydraulic bending machine of the present invention, the frame 2 is in the shape of an inverted U, and is fixedly mounted on the base 1 . The guide post 3 is located in the frame 2, and the guide post 3 is two vertically set up on both sides inside the frame 2. The hydraulic jack 9 is erected on the top of the frame 2, the output shaft of the hydraulic jack 9 passes through the frame 2 downward, and the output shaft of the hydraulic jack 9 is fixedly connected with the connecting block 8. The hydraulic jack 9 is connected to a control unit 11, and the control unit 11 controls the movement of the output shaft.

[0013] Both ends of the connecting block 8 are provided with openings corresponding to the guide post 3 , the connecting block 8 is sleeved on the guide post 3 , and the connecting block 8 can move up and down ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com