Machining device for construction steel bar and application method thereof

A technology for building steel bars and processing devices, which is applied in the field of construction equipment, can solve problems such as single functions, and achieve the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

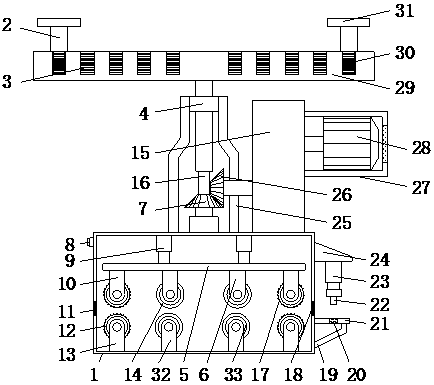

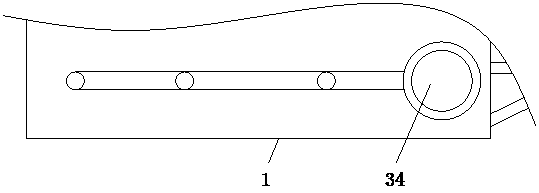

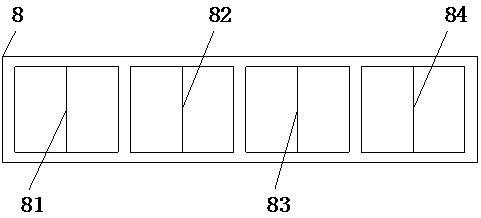

[0025] see Figure 1-4 , a processing device for building steel bars, comprising a straightening box 1, the top of the inner cavity of the straightening box 1 is fixedly connected with a first electric telescopic rod 9, and the first electric telescopic rod 9 is set in two groups, and each group of the first electric telescopic rod The quantity of telescopic link 9 is two, and by support plate 5, last conveying roller support 10, last conveying roller 17, last conveying roller support 10 and upper guide roller support 6 and following conveying roller support 13, following conveying roller 12, The role of the lower guide roller bracket 32 and the lower guide roller 33 can realize the straightening requirements for steel bars of different diameters, and the bottom of the first electric telescopic rod 9 is fixedly connected with the support plate 5, and the left and right ends of the support plate 5 bottom are all fixed. Be connected with upper conveying roller support 10, and ...

Embodiment 2

[0031] see Figure 1-4 , a processing device for building steel bars, comprising a straightening box 1, the top of the inner cavity of the straightening box 1 is fixedly connected with a first electric telescopic rod 9, and the first electric telescopic rod 9 is set in two groups, and each group of the first electric telescopic rod The quantity of expansion link 9 is three, and by support plate 5, last conveying roller support 10, last conveying roller 17, last conveying roller support 10 and upper guide roller support 6 and following conveying roller support 13, following conveying roller 12, The role of the lower guide roller bracket 32 and the lower guide roller 33 can realize the straightening requirements for steel bars of different diameters, and the bottom of the first electric telescopic rod 9 is fixedly connected with the support plate 5, and the left and right ends of the support plate 5 bottom are all fixed. Be connected with upper conveying roller support 10, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com