Small reinforcing steel bar bending device

A steel bar and small technology, applied in the field of small steel bar bending equipment, can solve the problems of large space occupation, inconvenient use, limitation of bending steel bar length and radian, etc., and achieve the effect of large length range, simple structure and convenient transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below with reference to the accompanying drawings and examples, and the embodiments of the present invention include but not limited to the following examples.

[0014] In order to achieve the above object, the technical scheme adopted in the present invention is as follows:

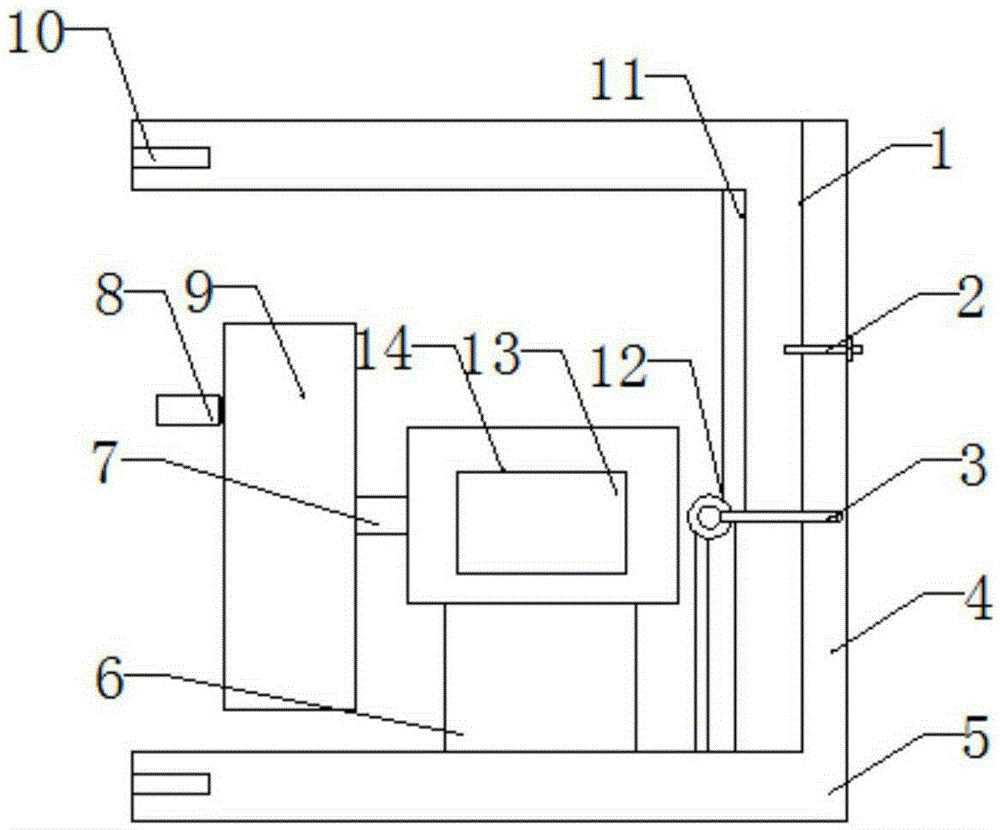

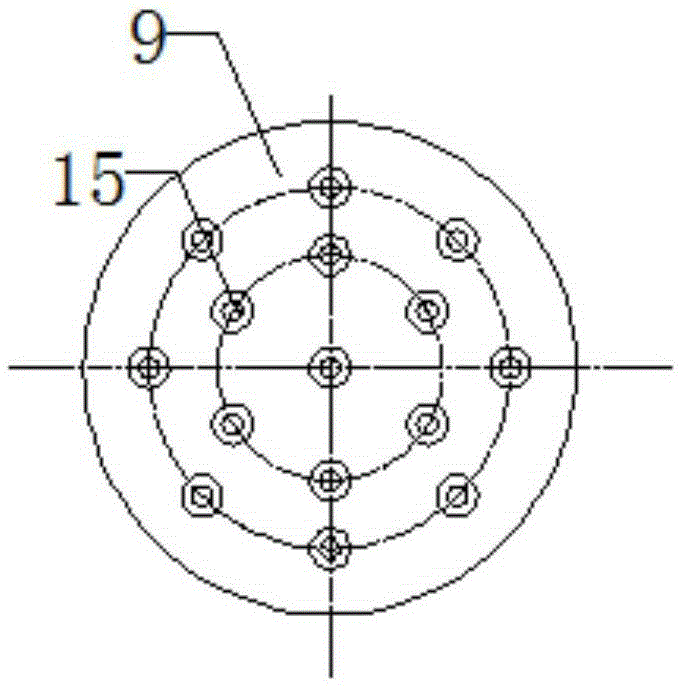

[0015] This small steel bar bending equipment includes an upper moving part 1, a set bolt 2, a handle 3, a body 4, a base 5, a fixed frame 6, a rotating shaft 7, a fixed pin 8, a turntable 9, a slot 10, and a rack 11 , gear 12, operation panel 13, motor 14 and tapered hole 15; the rack 11 is fixedly connected on the upper moving part 1, the operation panel 13 is fixedly connected with the motor 14, the motor 14 is connected to the turntable 9 through the rotating shaft 7, and the motor 14 is fixedly connected On the fixed frame 6, the fixed frame 6 is welded with the base 5, the handle 3 is fixedly connected to the gear 12, the gear 12 meshes with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com