Half-bent printed circuit board and making method thereof

A printed circuit board and manufacturing method technology, applied in printed circuit manufacturing, printed circuit, printed circuit components and other directions, can solve the problems of high cost, long cycle, complex rigid-flex board processing process, etc. Simple, ensure reliability, and solve the effect of solder resist cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] This embodiment provides a half-bent printed circuit board and a manufacturing method thereof. The preparation method comprises the following steps:

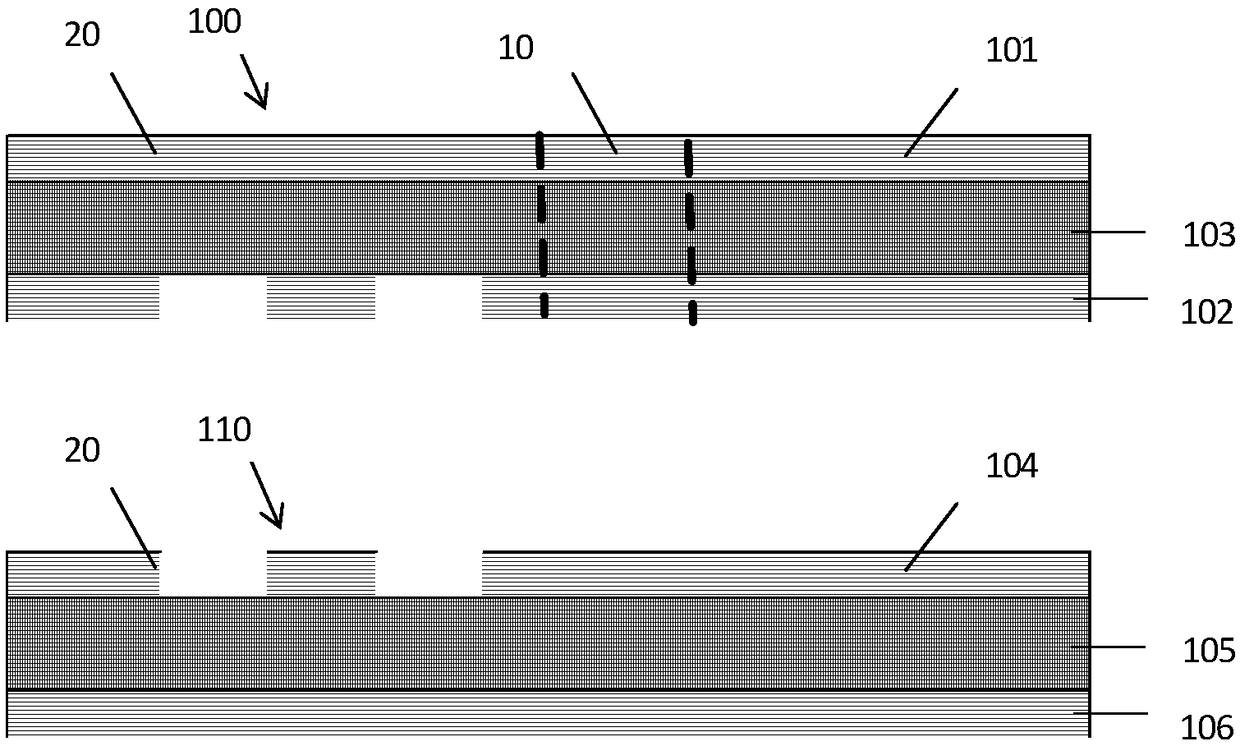

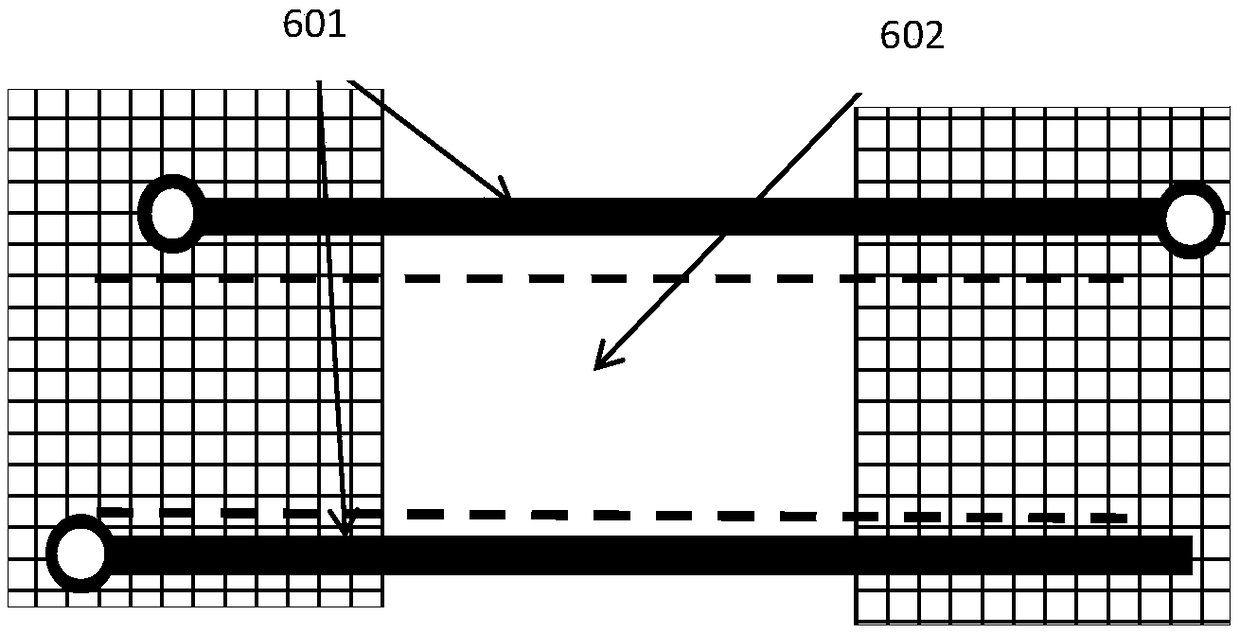

[0038] Step (1), see figure 1 : take the first double-sided copper-clad laminate and make the inner layer circuit to form the first inner layer circuit board 100 including the first outer layer copper foil layer 101 and the first inner layer circuit layer 102; the first inner layer circuit board 100 It is divided into a non-bending area 20 and a bending area 10; the copper-free area of the first inner circuit layer 102 in the bending area 10 is provided with a non-conducting line, and at least one end of the non-conducting line extends into the non-bending area. area, and the non-conductive line is not in contact with the conductive line of the first inner circuit layer 102 .

[0039] In this embodiment, the first double-sided copper-clad laminate is a common double-sided copper-clad laminate in the field, including t...

Embodiment 2

[0065] This embodiment is a modification example of Embodiment 1, and also provides a half-bent printed circuit board and a manufacturing method thereof. Compared with the preparation method of embodiment 1, the changes of this production method mainly include:

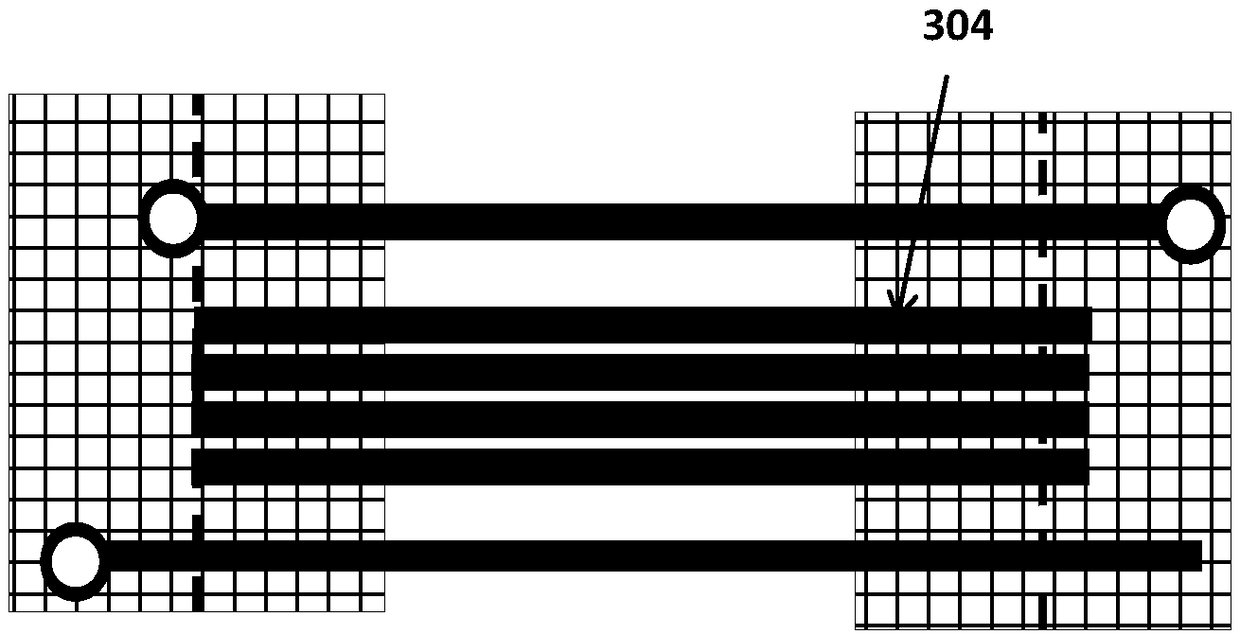

[0066] In step (1): the non-conducting line 304 satisfies the following conditions:

[0067] 1) The non-conductive wire is copper wire ( Figure 4 middle a);

[0068] 2) Lead wire ( Figure 4 Middle b) and non-conductive line 304 ( Figure 4 Middle a) is consistent with the bending direction;

[0069] 3) The minimum distance e between the preset component hole or pad and the boundary of the bending area in the non-bending area is 1 mm. At the same time, the distance c of the non-conducting line extending out of the bending area is 1mm;

[0070] 4) The width and line gap of the non-conducting line a are equal to 2 mm.

[0071] In step (5), the total thickness of the first ink layer and the second ink layer is 25...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com