Curtain wall metal structure vertical keel and vertical keel and transverse keel connecting structure

A vertical keel and metal structure technology, applied in the direction of walls, building components, building structures, etc., can solve the hidden problems of welding quality curtain wall construction quality, resistance can not be too large, life is shortened, etc., to achieve fast and convenient adjustment of position, Reliable plug connection and length reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

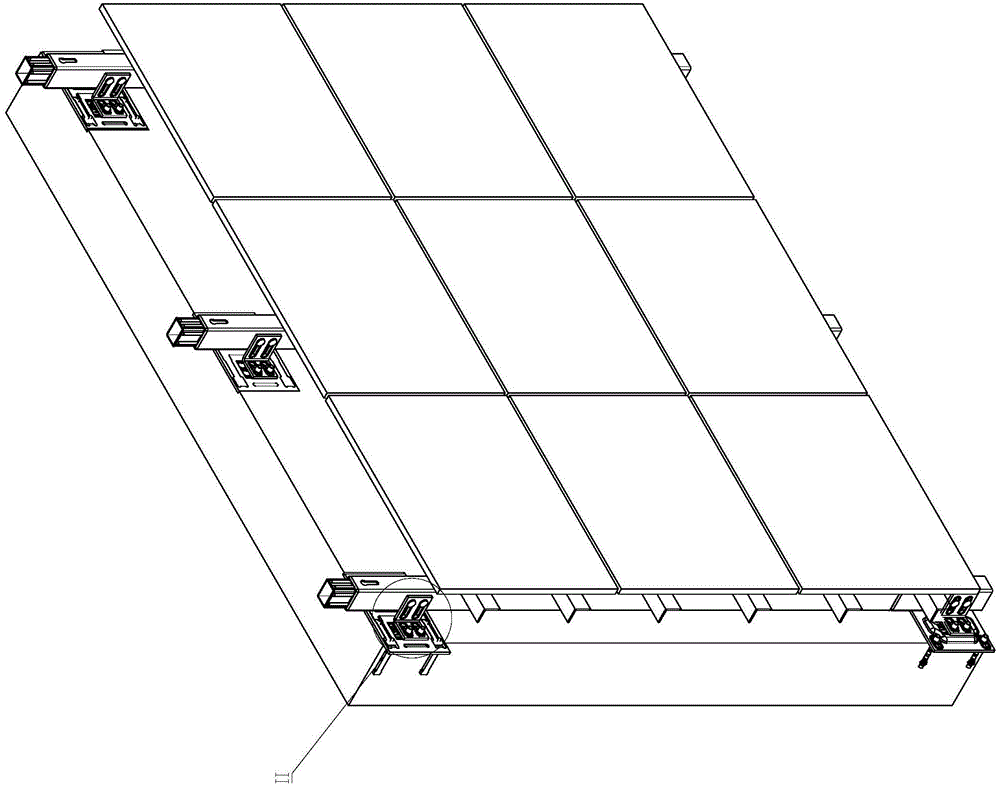

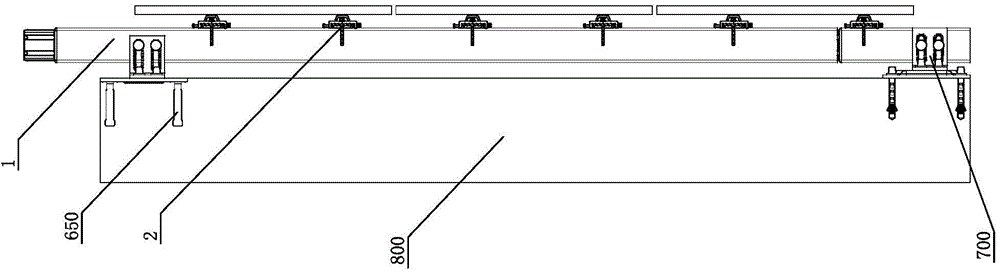

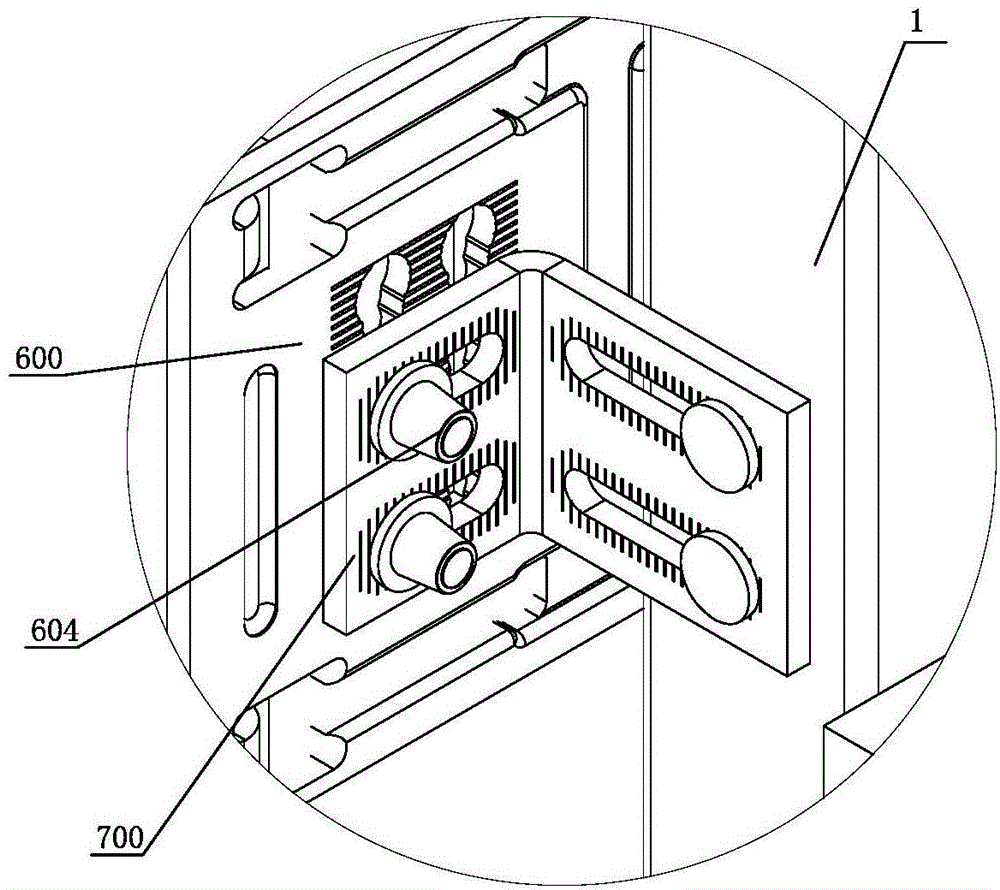

[0077] refer to Figure 1a , 1b , 2a, 2b. The vertical keel 1 of the curtain wall metal structure provided by the present invention is a square tube keel, and one end of the vertical keel is extruded into a joint square tube shape 1-1, and the surface of the joint square tube shape has vertical protrusions 1-2, to form a plug-in part integrated with the square tube keel for heat expansion, cold-contraction and compression resistance, with the overall size of the cross-section being consistent up and down. The plug-in part can match the size of the other end of the square tube keel, so that The insertion part of one vertical keel can be inserted into another square tube keel with interference or transition fit. The vertical protrusions 1-2 serve to reinforce the square tube shape of the butt joint and can not only achieve interference or transition fit when plugged in with the adjacent vertical keel, but also make the plugged in easier.

[0078] The overall size of the cross-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com