Method for setting bracing column in underground cavity

A technology for underground caverns and support columns, applied in the field of support columns, can solve the problems of the gap between the grouting surface and the cave roof, the inability to fill the space, and the increase of engineering costs, so as to avoid invalid grouting, save materials, protect The effect of ecological environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

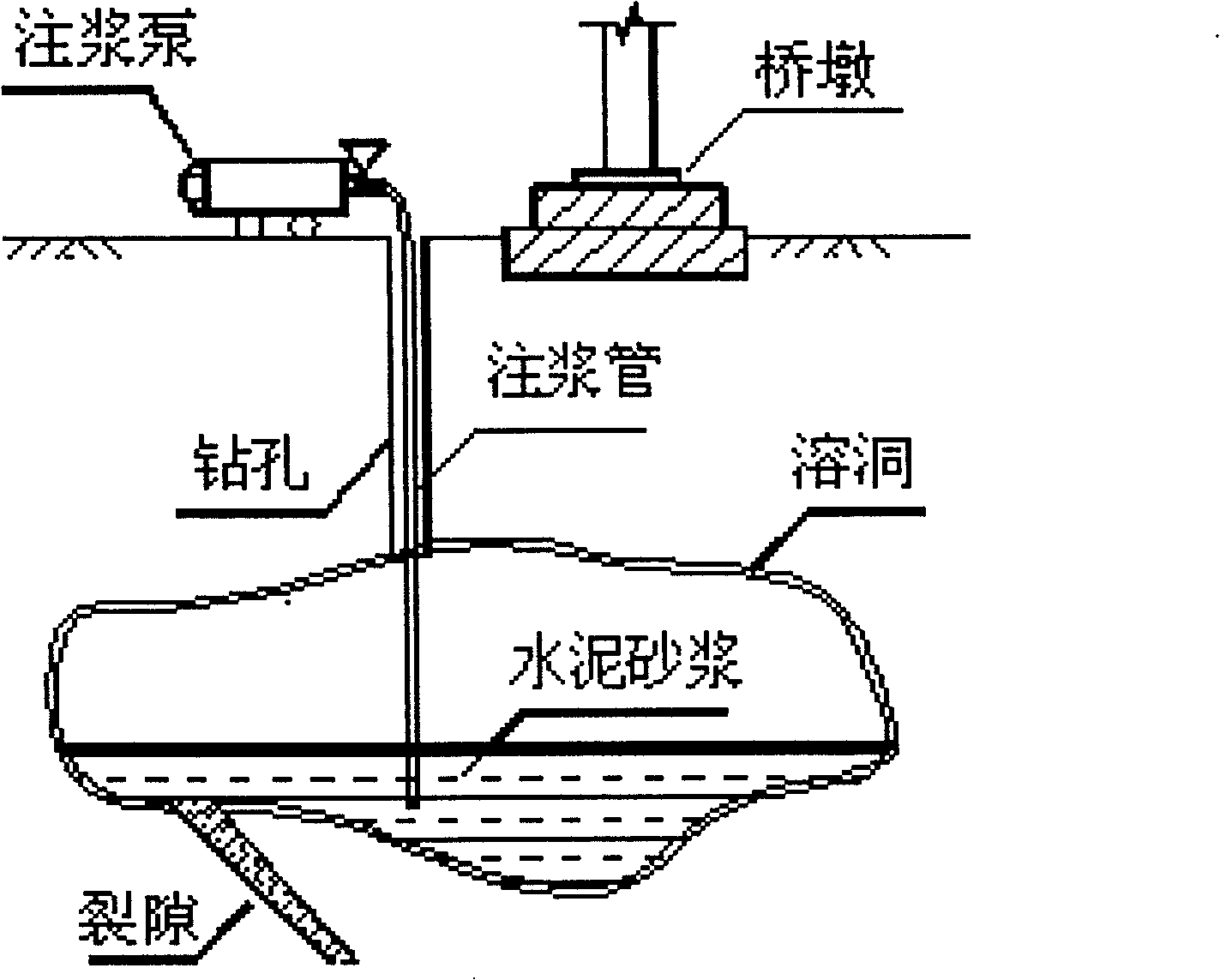

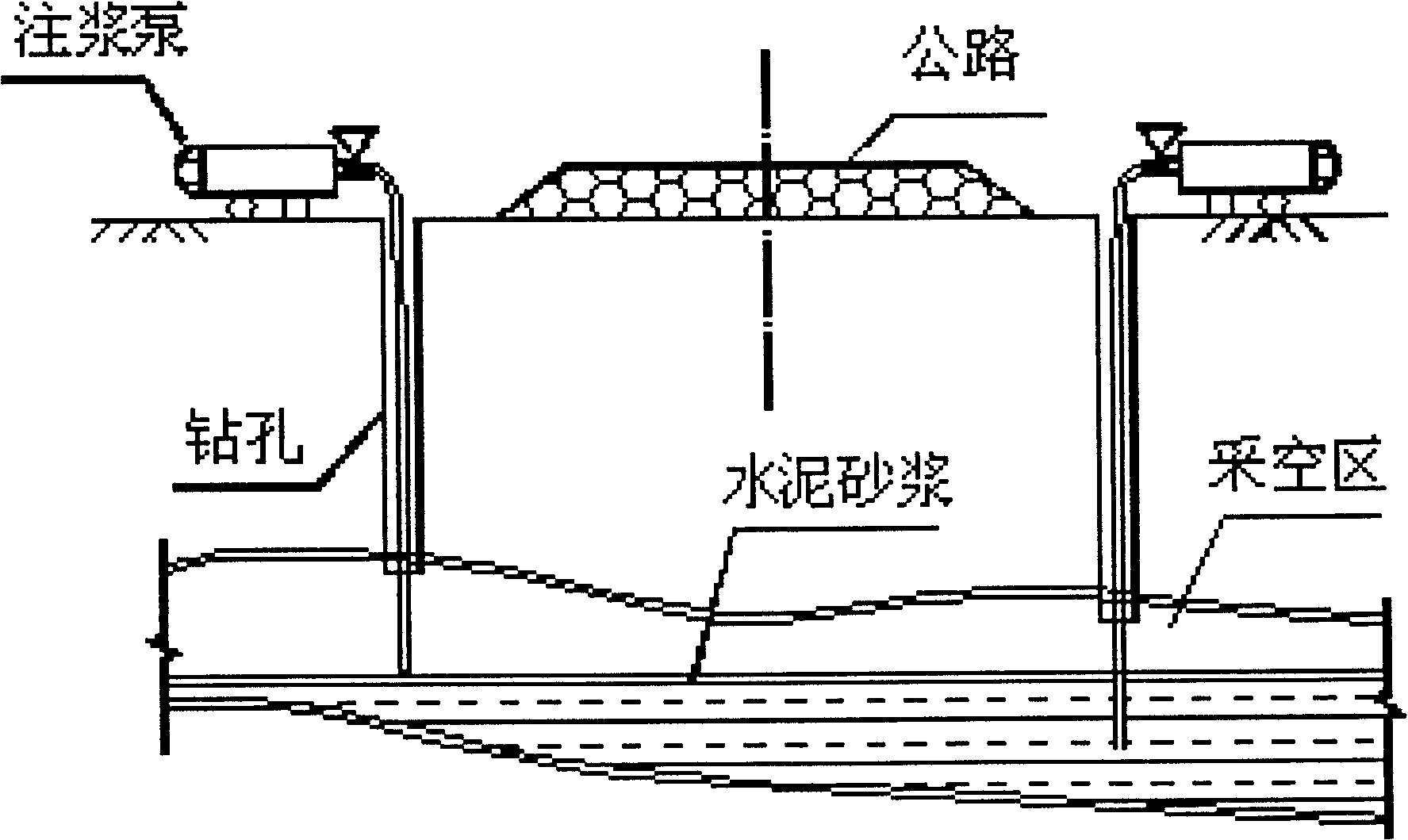

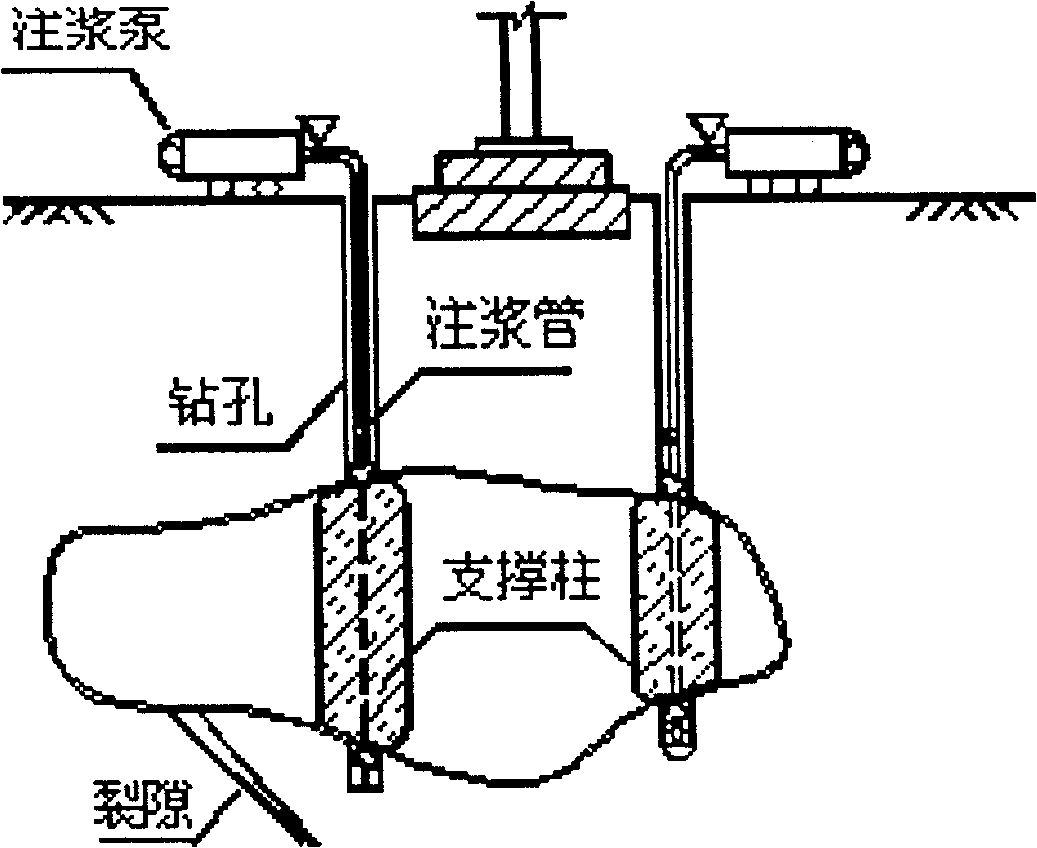

[0020] attached Figure 5 It is a specific embodiment of the present invention. Among them: 1-drilling; 2-the rope binding the lower opening of the bag or the upper opening of the bag; 3-the bag for filling cement mortar; 4-steel pipe; 5-the hole on the steel pipe wall for the outflow of cement mortar; 6 - Inner pull rope; 7 - Mortar; 8 - Bottom plug located in the lower end of the steel pipe for blocking the lower nozzle; 9 - Grouting pipe.

[0021] The implementation process of the present invention is as follows:

[0022] Use a drilling rig on the ground to drill hole 1 into the underground cavity. The diameter of hole 1 can be 9 to 13 cm. You can also drill a hole with a larger diameter according to the design requirements. After drilling through the top of the hole, continue drilling to the bottom of the cavity. , until the drilling reaches 40-60 cm below the bottom of the cavern. Get the steel pipe 4 whose outer diameter is smaller than the borehole diameter and whose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com