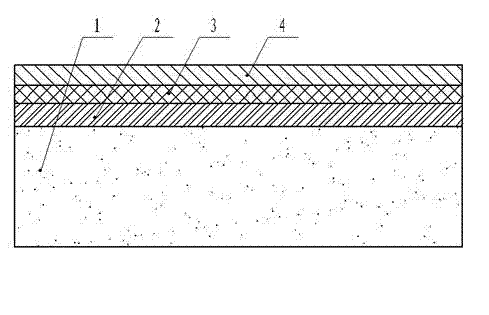

Self-cleaning layer with photocatalysis and anti-static compounding functions and production method thereof

A composite function, anti-static layer technology, applied in coatings, conductive coatings, layered products, etc., can solve problems such as poor workability and insignificant self-cleaning effect, and achieve easy cost control, good anti-static, and reduced molecular attraction force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0047] 1) Pickling the surface of the cement board that needs to be self-cleaning to remove dust, dirt and impurities on the surface of the cement board, and then dry it naturally for 2 hours to ensure that the surface of the substrate is clean and dry.

[0048] 2) Configure a silicone water repellent suspension with a mass percentage concentration of 0.5%, spray evenly on the surface of a clean and dry substrate with a spray gun, and control the spraying amount at 0.1L / m 2 , Dry naturally for 60 minutes after spraying to form a closed layer.

[0049]3) According to the proportion by weight, 5kg (5%) of film-forming agent fluorocarbon resin, 0.1 kg (0.1%) of film-forming agent polyethylene glycol, 2kg (2%) of 5nm nano-tin oxide, and 20m nano-oxide Silver 0.5kg (0.5%), 10nm nano-silicon oxide 1kg (1%), methanol 35kg (35%), deionized water 56.4kg (56.4%), stir well and make anti-static material stock solution for later use.

[0050] 4) Pour the prepared antistatic material stoc...

Embodiment example 2

[0056] 1) Wash the glass surface that needs to be self-cleaning to remove dust, dirt, and impurities on the glass surface, and then dry it naturally for 8 hours to ensure that the surface of the substrate is clean and dry.

[0057] 2) Configure a silicone water repellent suspension with a concentration of 1% by mass, spray evenly on the surface of a clean and dry substrate with a spray gun, and control the spraying amount at 0.01L / m 2 , Dry naturally for 30 minutes after spraying to form a closed layer.

[0058] 3) 10kg (10%) of the film-forming agent butadiene resin, 1kg (1%) of 8nm nano-tin oxide, 0.5kg (0.5%) of 15nm nano-silver oxide, and 5kg of 8nm nano-silicon oxide according to the proportion by weight. (5%), ethanol 45kg (45%), deionized water 38.5kg (38.5%), stir well and make anti-static material stock solution for later use.

[0059] 4) Inject the stock solution of anti-static material into the chemical synthesis reaction kettle, control the speed at 400 rpm, contr...

Embodiment example 3

[0065] 1) Pickling the surface of the aluminum plate that needs to be self-cleaning to remove dust, dirt, and impurities on the surface of the aluminum plate, and then dry it naturally for 4 hours to ensure that the surface of the substrate is clean and dry.

[0066] 2) Configure the epoxy resin suspension with a mass percentage concentration of 2.5%, and spray it evenly on the surface of the clean and dry substrate with a spray gun, and the spraying amount is controlled at 0.2L / m 2 , Dry naturally for 90 minutes after spraying to form a closed layer.

[0067] 3) Mix 8kg (8%) of film-forming agent silane resin, 1.5 kg (1.5%) of film-forming agent low-molecular wax dispersant, 1.5kg (1.5%) of 5nm nano-silver oxide, and 5nm Nano silicon oxide 3kg (3%), ethylene glycol 40kg (40%), deionized water 46kg (46%), stir well and make anti-static material stock solution for later use.

[0068] 4) Pour the stock solution of the prepared anti-static material into the chemical synthesis re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com