Composite electrode for catalyzing oxidation of sodium formate, and preparation method and application thereof

A technology for catalyzing sodium formate and composite electrode is applied in the field of composite electrode catalyzing the oxidation of sodium formate and its preparation, which can solve the problems of limiting the catalyst deposition amount, catalytic active area, etc., and achieve the effects of improving catalyst utilization rate, reducing transfer resistance, and shortening transfer path.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

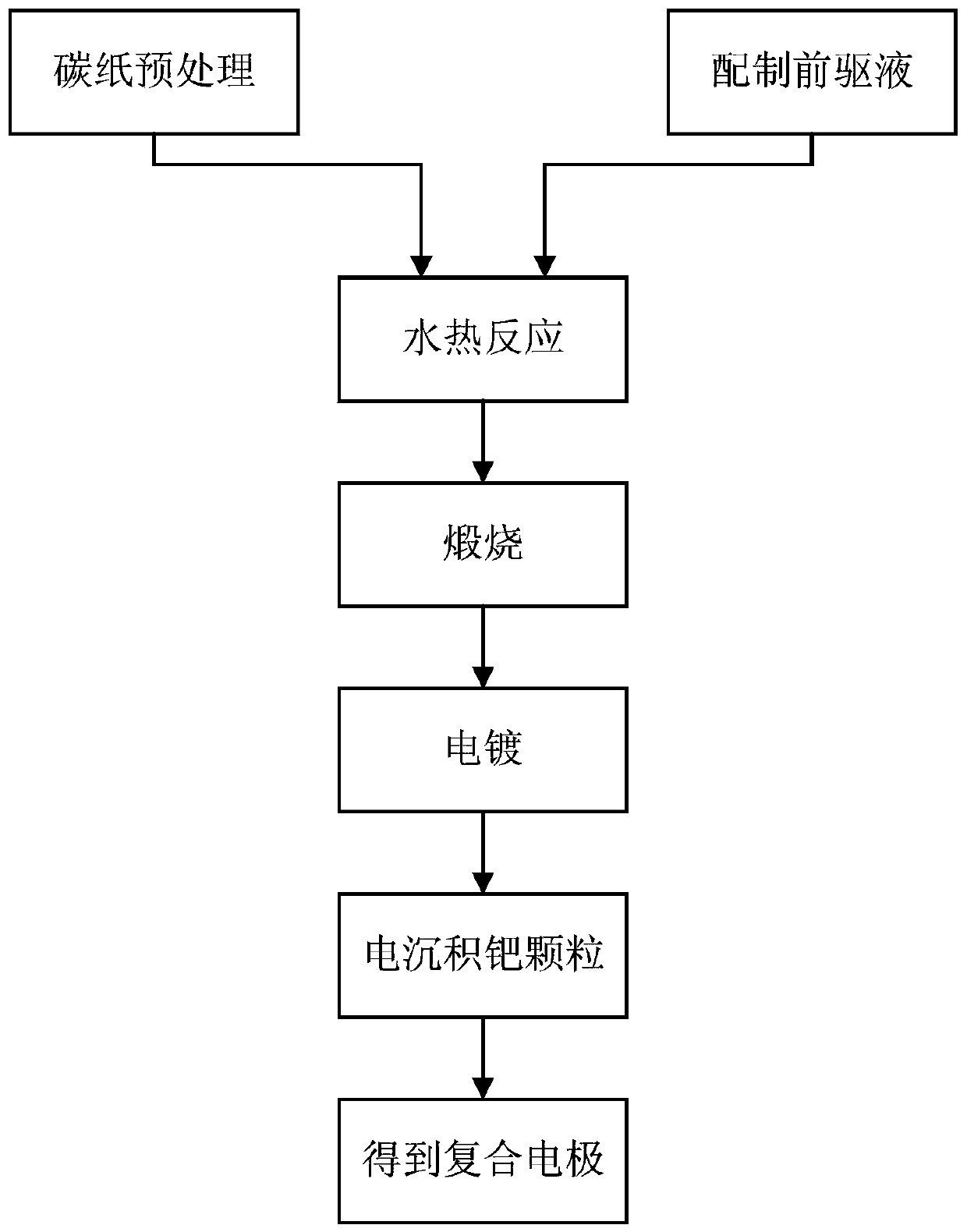

[0029] Example 1, see figure 1 , a method for preparing a composite electrode for catalyzing the oxidation of sodium formate, comprising the following steps:

[0030] A. Put the hydrophilic carbon paper in absolute ethanol for ultrasonic cleaning, then put it into deionized water for ultrasonic cleaning to remove the oil on the surface of the carbon paper, and dry the cleaned carbon paper for later use;

[0031] B. Dissolve cobalt nitrate, ammonium fluoride and urea in deionized water and stir fully to dissolve it to obtain a precursor solution;

[0032] C, transfer the cleaned carbon paper and the precursor solution obtained in step B to a reaction kettle for hydrothermal reaction;

[0033] D. After the hydrothermal reaction is completed, cool to room temperature, take out the carbon paper, rinse it repeatedly with absolute ethanol and deionized water, put it in an oven to dry, and then put the carbon paper with the precursor in the tube furnace in the air atmosphere Calcin...

Embodiment 2

[0040] (1) Put the hydrophilic carbon paper in anhydrous ethanol for 5 minutes and then ultrasonically clean it in deionized water to remove the oil on the surface of the carbon paper. Dry the cleaned carbon paper for later use.

[0041] (2) Dissolve 2mmol of cobalt nitrate, 4mmol of ammonium fluoride, and 10mmol of urea into 50% deionized water and magnetically stir for 15min to dissolve.

[0042] (3) Pour the completely dissolved precursor solution into the lining of a 100mL polytetrafluoroethylene reactor, and then put in carbon paper, so that the carbon paper is completely immersed in the precursor solution, and then seal the lining into the autoclave sleeve, and place it in an oven at 120° Hold for 5 hours.

[0043] (4) Take out the carbon paper after hydroheating in step (3), rinse it repeatedly with absolute ethanol and deionized water, and put it into an oven to dry.

[0044] (5) Put the carbon paper with the precursor into the tube furnace for calcination at 350°C f...

Embodiment 3

[0048] (1) Put the hydrophilic carbon paper in anhydrous ethanol for 5 minutes and then ultrasonically clean it in deionized water to remove the oil on the surface of the carbon paper. Dry the cleaned carbon paper for later use.

[0049] (2) Dissolve 2.5mmol of cobalt nitrate, 5mmol of ammonium fluoride, and 12.5mmol of urea in 30mL of deionized water and magnetically stir for 20min to dissolve.

[0050] (3) Pour the completely dissolved precursor solution into the lining of a 100mL polytetrafluoroethylene reactor, and then put in carbon paper, so that the carbon paper is completely immersed in the precursor solution, and then seal the lining into the autoclave sleeve, and place it in an oven at 120° Hold for 5 hours.

[0051] (4) Remove the carbon paper after hydroheating in step (3), rinse it repeatedly with absolute ethanol and deionized water, and put it into an oven to dry.

[0052] (5) Put the carbon paper with the precursor into the tube furnace for calcination at 350...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com