Hydrophilic mirror coated tio2 membrane on chrome plate and manufacturing process thereof

A hydrophilic and coating technology, applied in the field of hydrophilic mirrors, can solve the problems of weak hydrophilic performance, poor crystal structure and exposure in the manufacturing process, and achieve the effect of super hydrophilic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

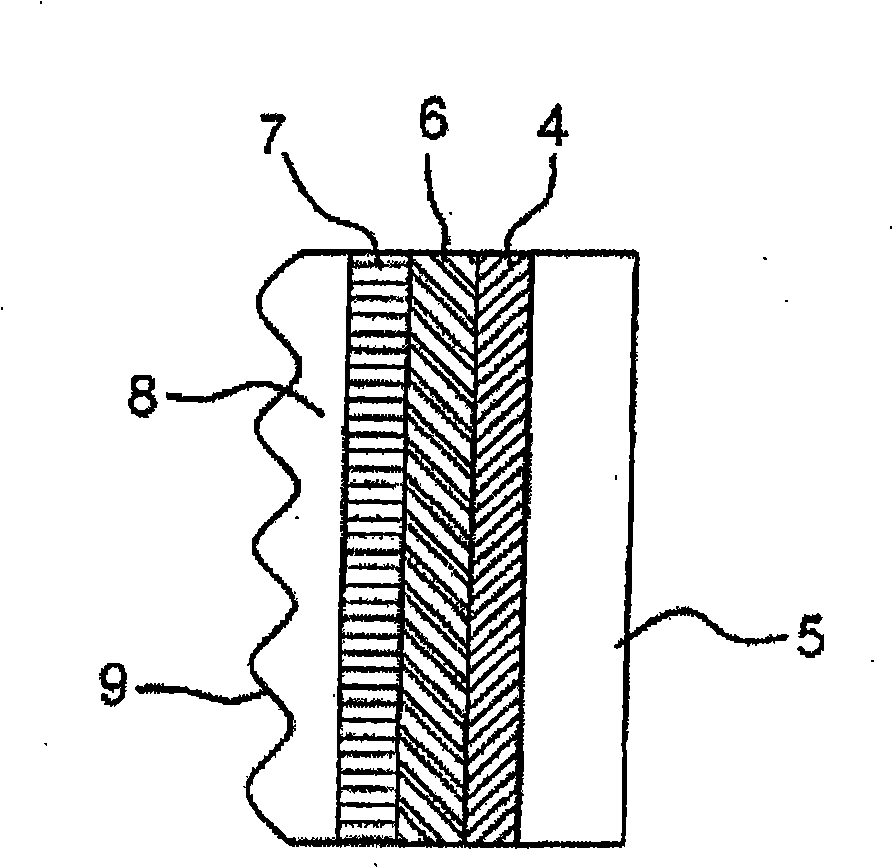

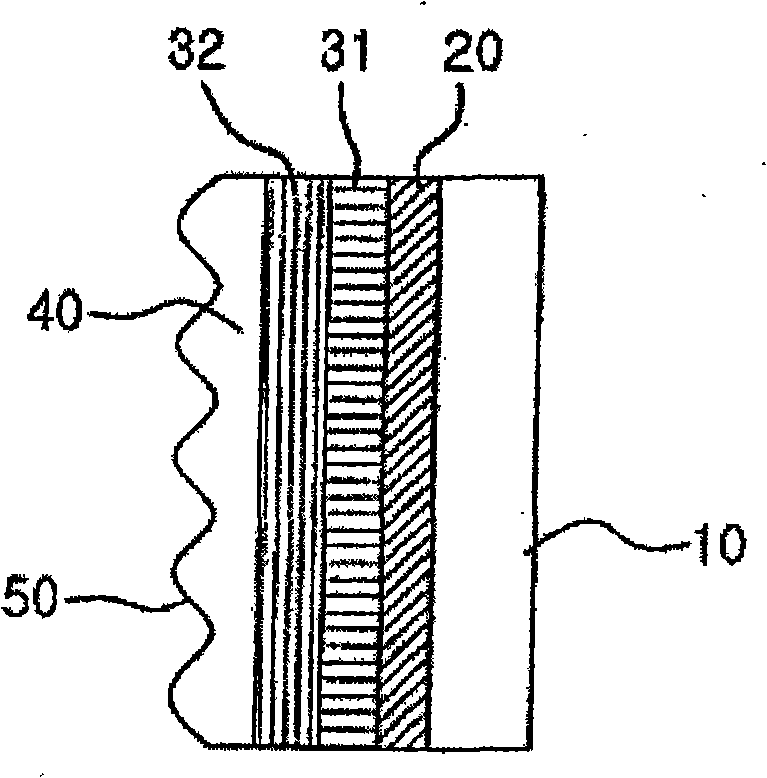

[0029] Hereinafter, exemplary embodiments of the present invention will be described in detail with reference to the accompanying drawings.

[0030] figure 2 is a sectional view of a hydrophilic photocatalyst according to an exemplary embodiment of the present invention, and a hydrophilic mirror of the photocatalyst according to the present invention uses a commercially available mirror coated with chromium as a substrate 10 .

[0031] Such as figure 2 As shown, according to the present invention, in order to use a commercial mirror comprising a chrome-plated layer 20 formed on a glass substrate 10 to manufacture a hydrophilic photocatalyst, the chrome-plated layer 20 is cleaned using ultrasonic waves in an acetone solution to remove Impurities or oxide layers on the chromium plating layer 20 .

[0032] Afterwards, a layer of amorphous (amorphous) titanium dioxide (TiO2) is coated on the chromium layer 20 using a sputtering method. 2 ) layer 31 (hereinafter referred to as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com