Fan blade assembly

a technology of blades and blades, applied in the direction of liquid fuel engines, marine propulsion, vessel construction, etc., can solve the problems of reducing the service life of the fan blade, so as to facilitate the accurate installation of the core shaft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

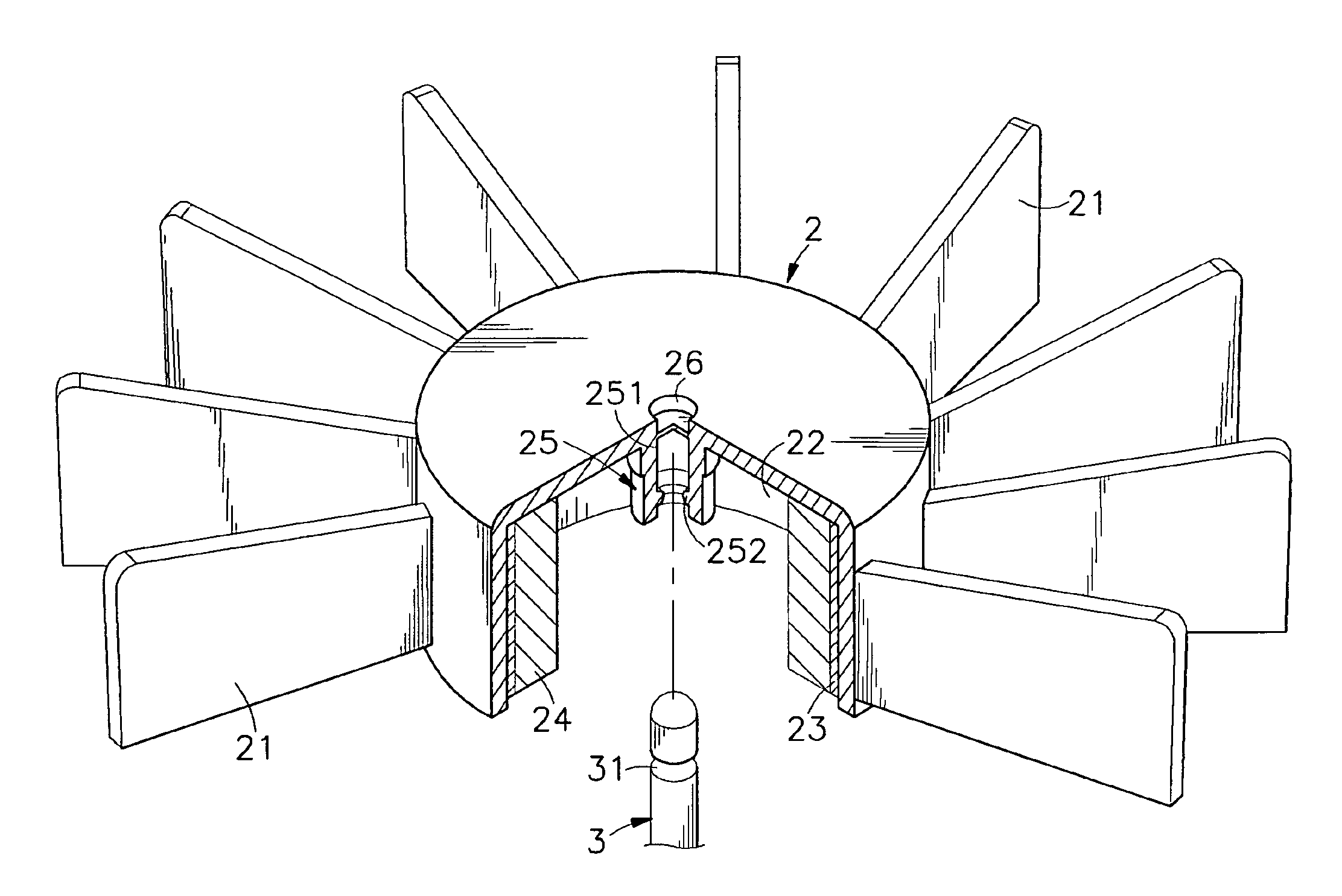

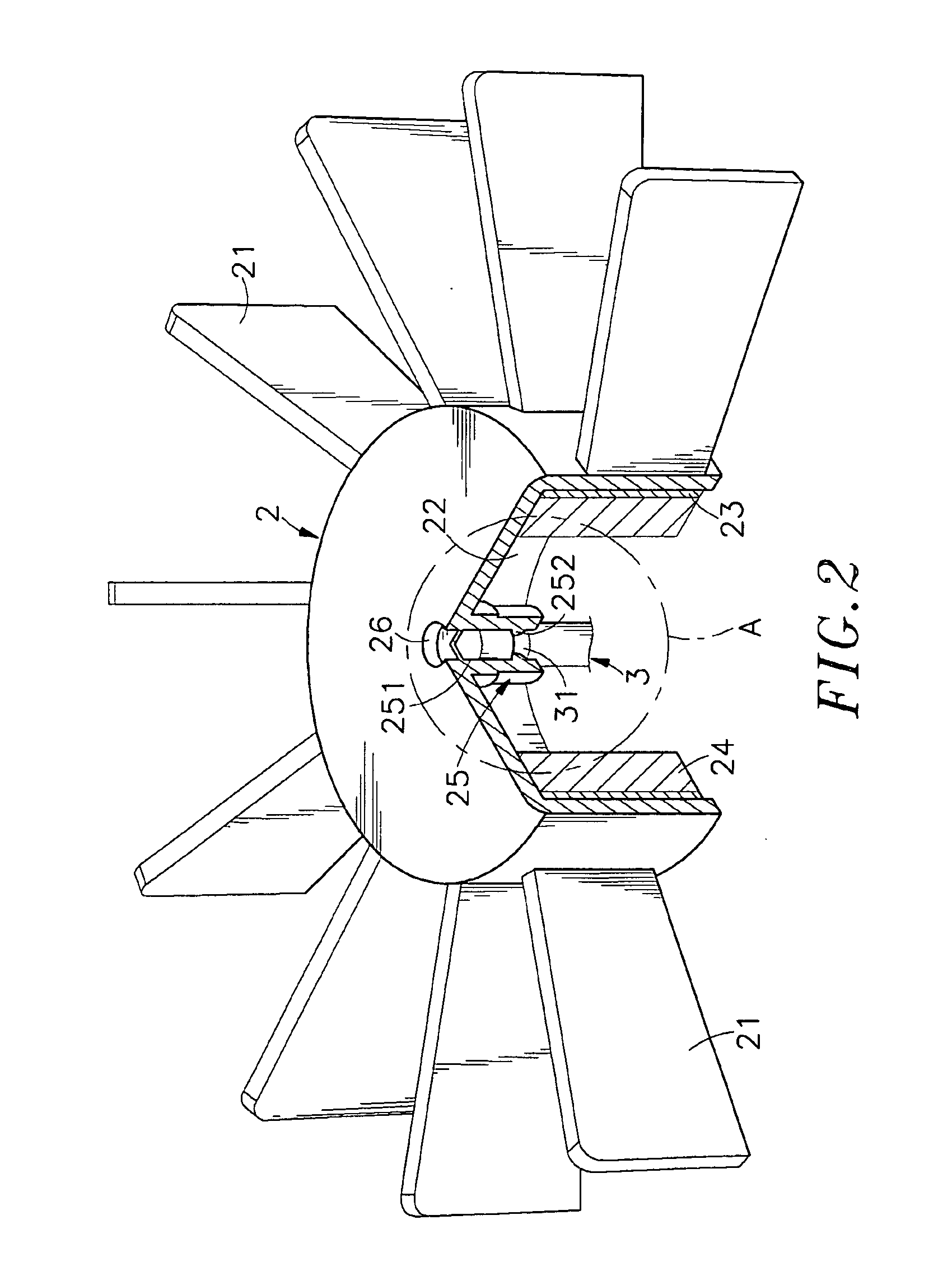

[0019]Referring to FIGS. 2˜4, a fan blade assembly in accordance with a first embodiment of the present invention is shown comprised of a fan blade body 2 and a core shaft 3.

[0020]The fan blade body 2 has an accommodation open chamber 22 disposed at the center and facing one side, namely, the bottom side, a plurality of radial blades 21 equiangularly spaced around the peripheral wall of the accommodation open chamber 22, a metal guide plate 23 mounted on the inner surface of the peripheral wall of the accommodation open chamber 22, a plurality of permanent magnets 24 affixed to the metal guide plate 23, a locating hole 26 located at the center of the top wall of the accommodation open chamber 22 and disposed outside the accommodation open chamber 22 for accommodating a magnetic member 27 (see FIG. 6), and an axle housing 25 downwardly extending from the center of the top wall of the accommodation chamber 22 opposite to the locating hole 26 and suspending inside the accommodation ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com