Accurate adjusting frame of high-speed railway ballastless track plate

A technology of ballastless track and high-speed railway, which is applied in the direction of track, track laying, track maintenance, etc. It can solve the problems of inconvenient installation, large influence of frame temperature, difficulty in frame packaging, transportation, and moving, etc., and achieves convenient installation Accurate and easy to move

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

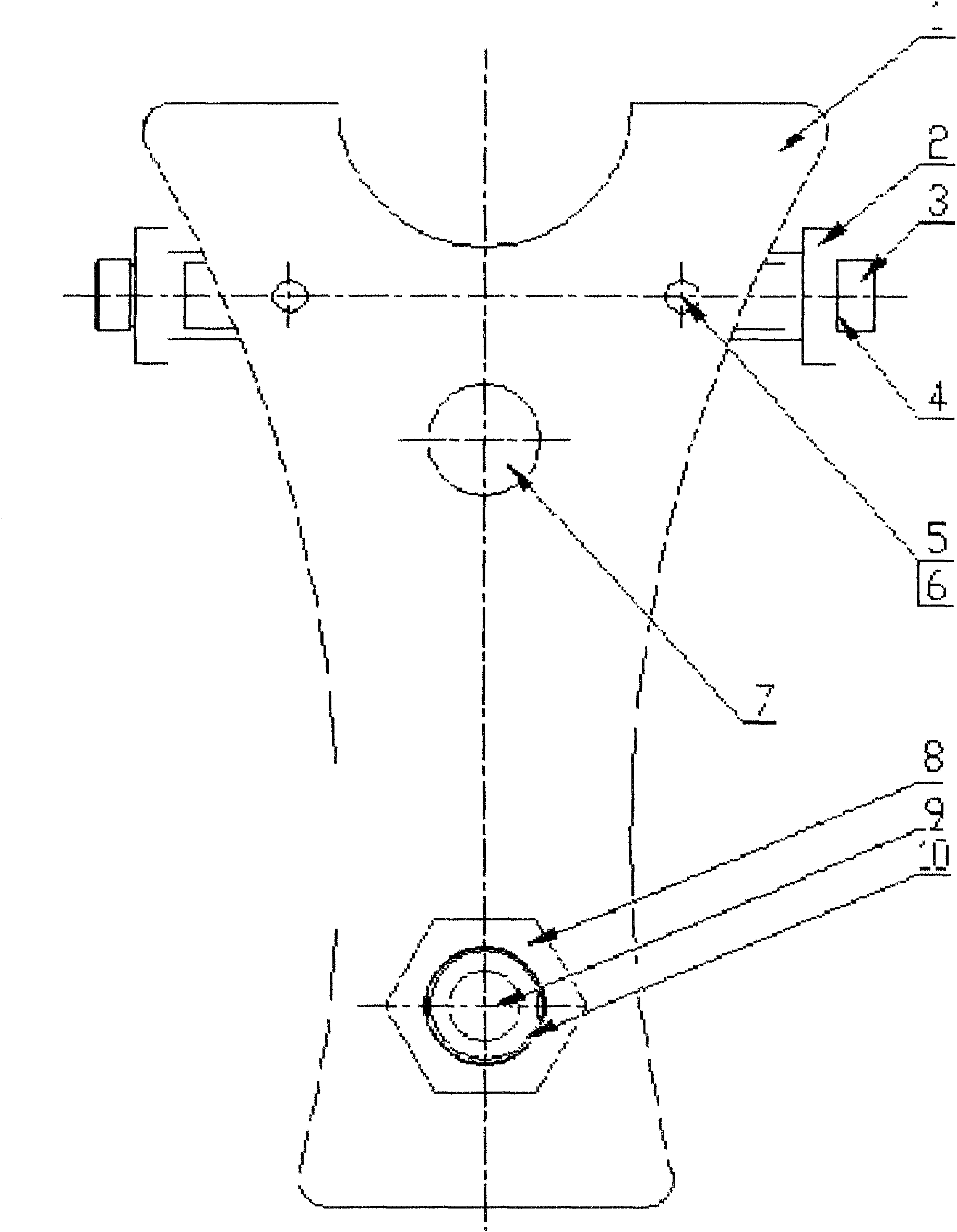

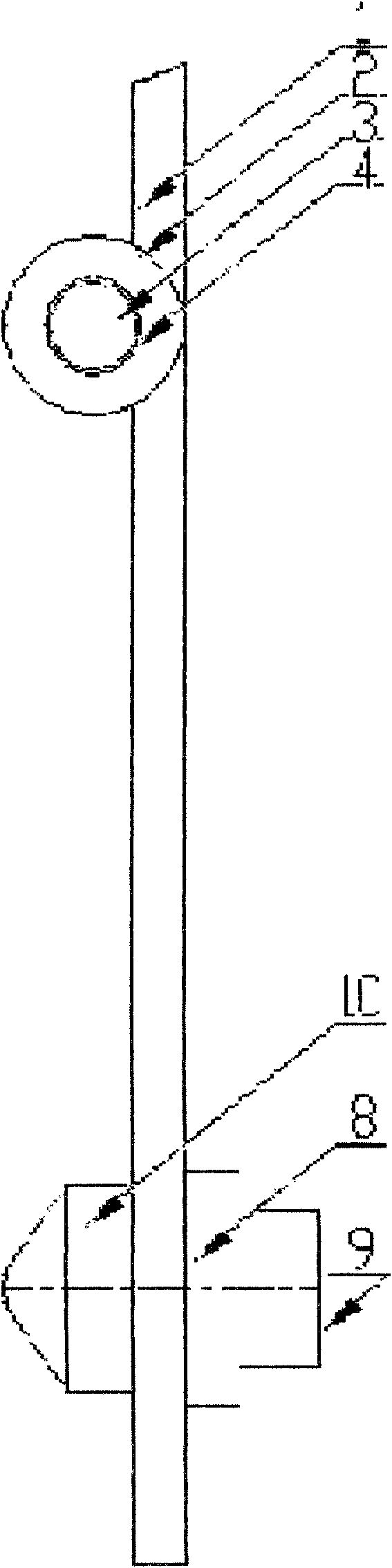

[0011] Such as figure 1 figure 2 As shown, the high-speed railway ballastless track slab fine adjustment frame of the present invention comprises a frame body (1), a pair of through holes (5) are arranged on the frame body (1), and the bearings (2) are installed on the two sides of the shaft (3). end, and clamped by the circlip (4), the shaft (3) has a pair of through holes, installed on the frame (1) through the screw (6) and the through hole (5), and the positioning rod (10) through the nut (8) Installed on the through hole of the frame body (1), a magnet (9) is installed on the top of the positioning rod (10) to install the measuring ball, and the through hole (7) on the frame body (1) is used to ensure that the frame Longitudinal placement accuracy.

[0012] The frame body (1) of key of the present invention, earlier the frame body (1) upper and lower surfaces are precision-machined into a plane, the external dimensions of the frame body (1) are processed, and a pair of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com