Directly driven synchronous dragger with Nd-Fe-B permanent magnetic rotor

An outer rotor and NdFeB technology, which is applied in the field of NdFeB permanent magnet outer rotor synchronous traction machines, modern elevator traction special driving devices, and outer rotor synchronous traction machines, can solve the problem of difficult stator core pressing and unloading. Lines, uneven rotor air gaps, poor structural manufacturability, etc., to achieve the effects of accurate leveling, compact structure, and reduced positioning torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to better understand the technical solution of the present invention, further detailed description will be given below in conjunction with the accompanying drawings.

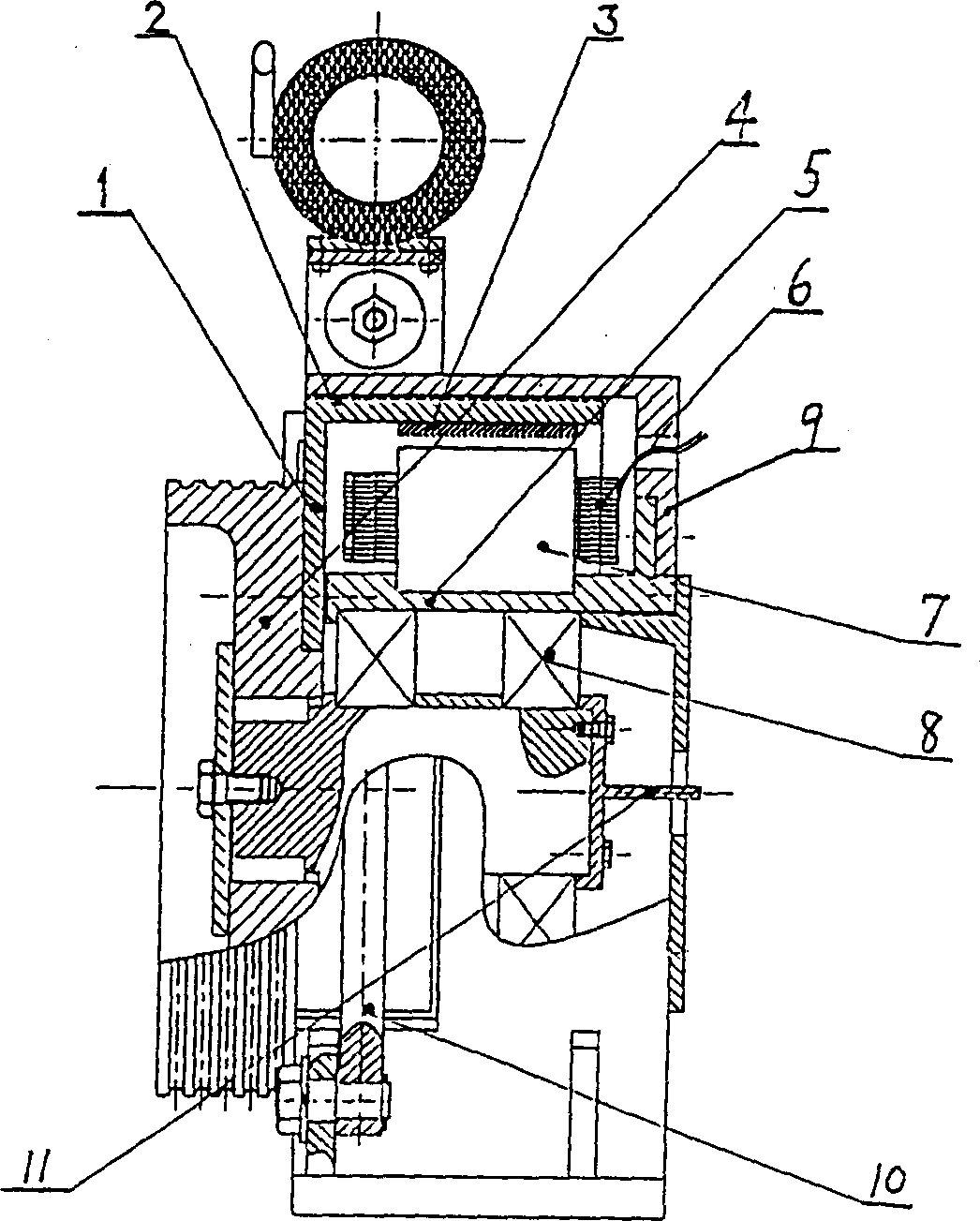

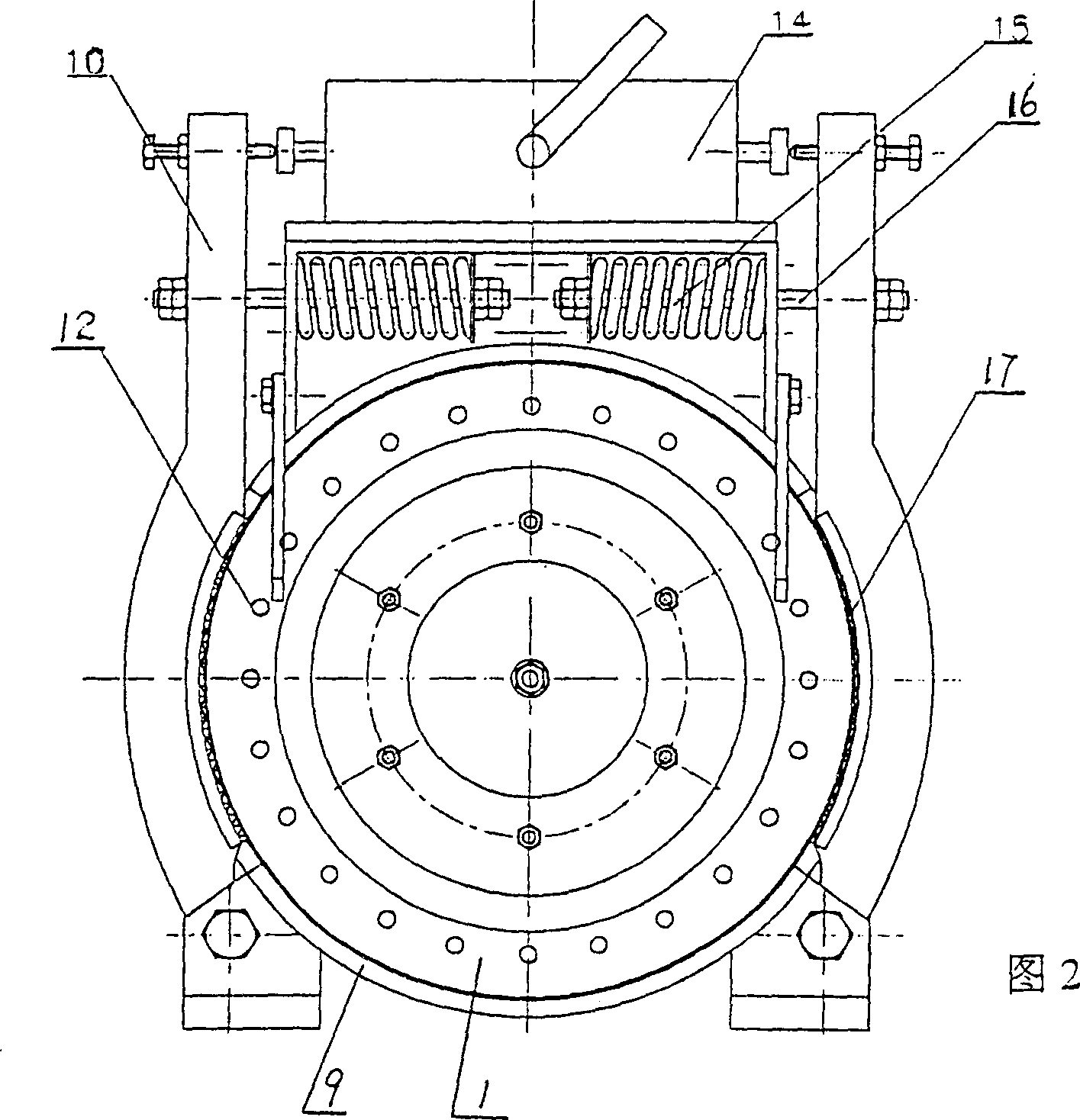

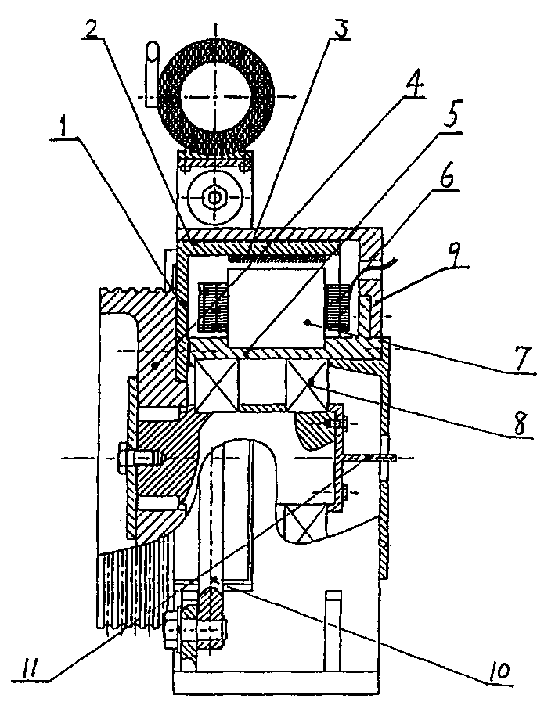

[0015] figure 1 It is a structural schematic diagram of the present invention.

[0016] As shown in the figure, the present invention adopts a multi-pole outer rotor structure. The yoke 2 of the outer rotor 1 not only serves as a support for the salient pole magnetic steel 3 to form the magnetic circuit of the motor, but also serves as a fixed support for the traction sheave 4. The outer rotor 1 is It can also be directly used as a brake wheel when power-off braking. The inner stator adopts a two-layer ring structure, which is composed of a stator inner ring 5 , a stator core 7 , an armature winding 6 and a stator outer ring 9 . The traction sheave 4 is fixed on the outer rotor 1 and is integrally connected with the outer rotor. Stator and rotor are supported by bearings 8 to ensure clearance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com