Three-dimensional motion multifunctional washing machine

A three-dimensional motion and multi-functional technology, applied in the field of washing machines, can solve the problems of unsuitable cleaning of high-grade fabrics, unbalanced clothes and easy entanglement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

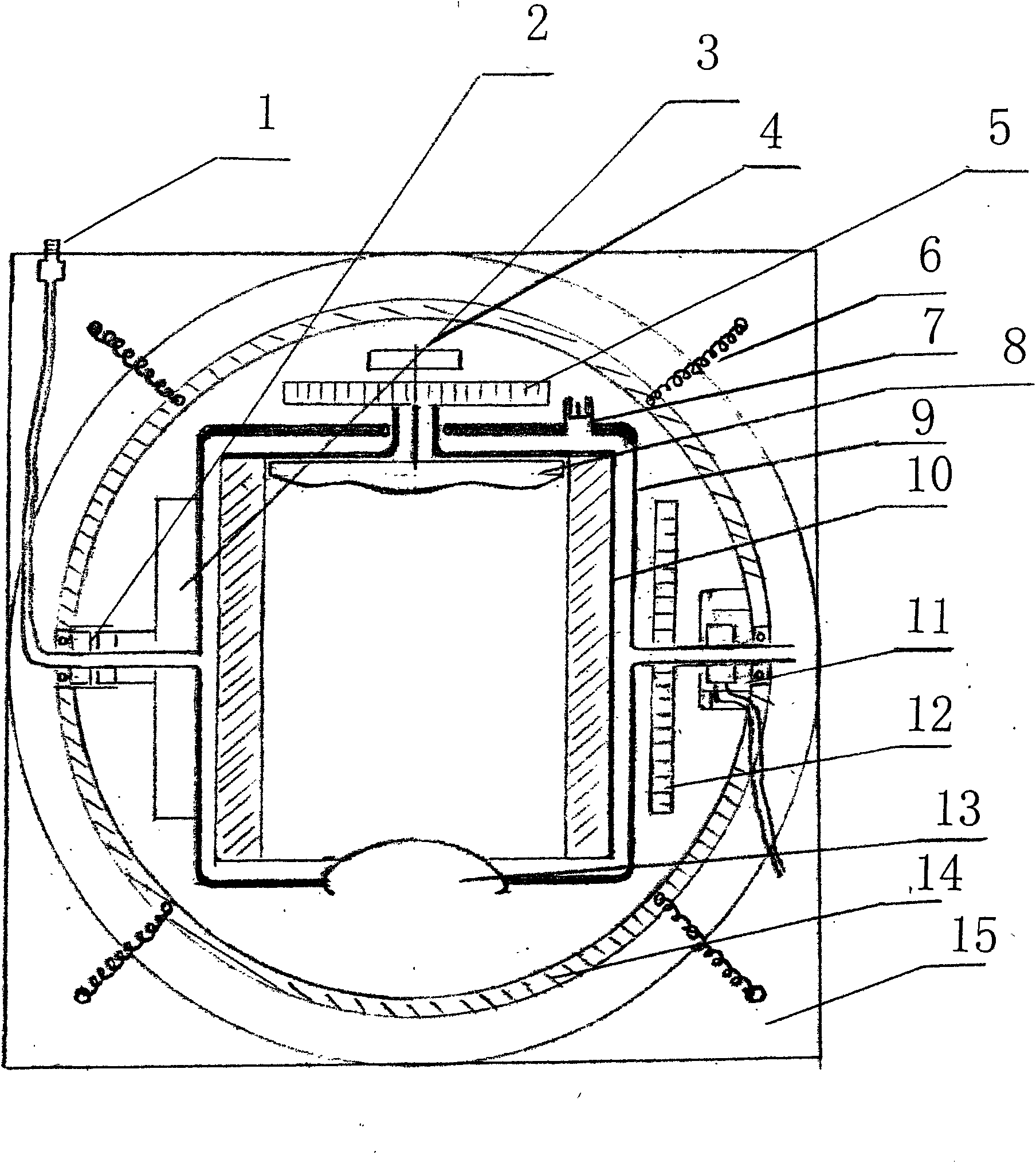

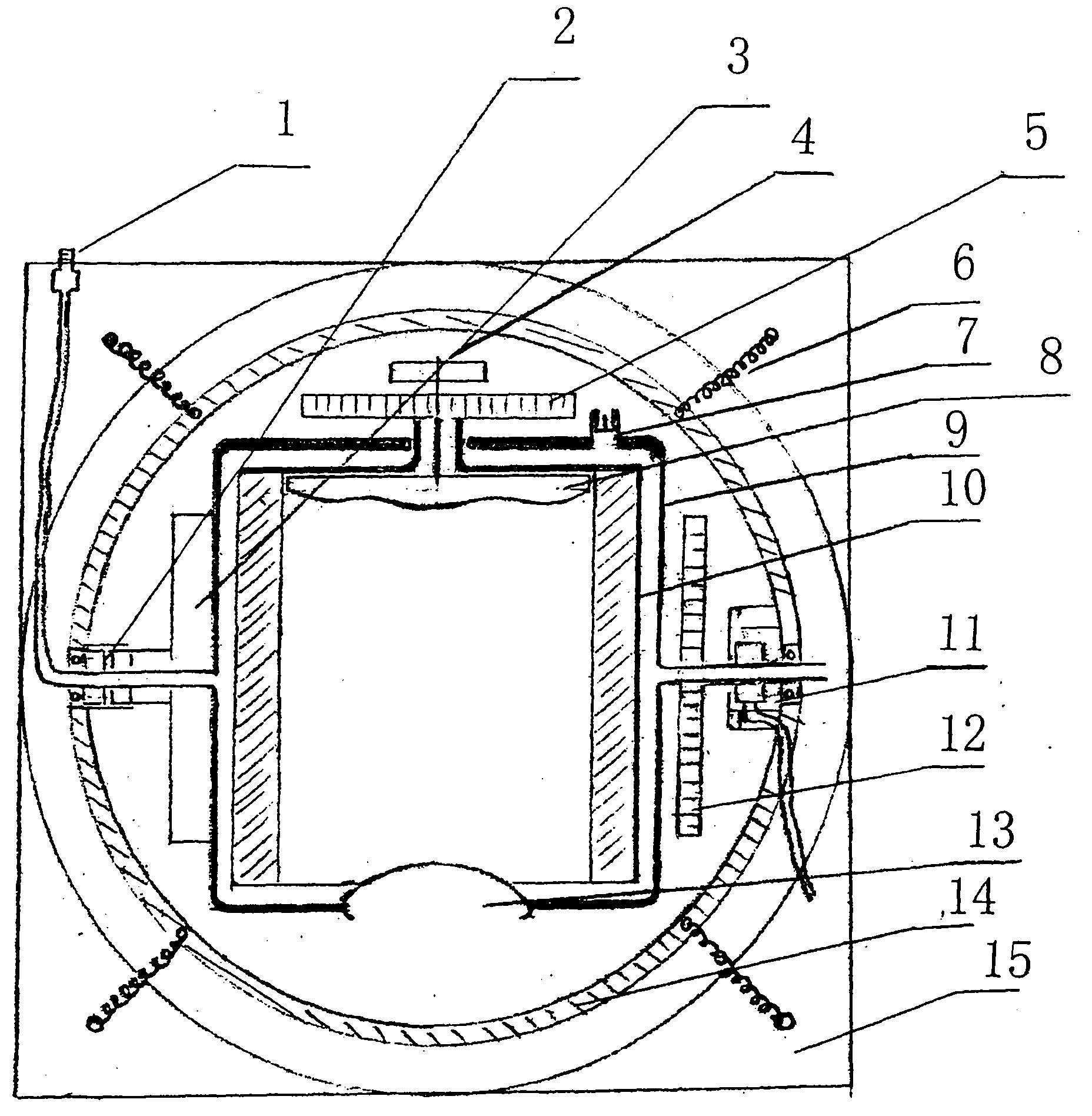

[0013] The shell (15) hangs the load-bearing rings in it through the suspension springs, and the load-bearing rings are connected with the outer barrel through the left and right support connecting rods. The outer barrel is driven by the outer barrel drive motor to rotate up and down. The discs (8) are driven by their own drive motors to rotate around the inside of the outer barrel (9) in various ways. The left support link has both water inlet function and power supply function, and the right support link has both drainage function and signal input and output. function, as shown in the figure. , mainly has the following functions.

[0014] 1: When the outer tub (9) rotates around the horizontal axis until it is perpendicular to the ground, the pulsator drive motor (4) drives the pulsator to rotate, and at this time the pulsator is in the washing state.

[0015] 2: When the outer tub (9) rotates around the horizontal axis until it is level with the ground, the drum drive moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com