High-temperature-resistant clean type self-adhesive protection film and preparation method thereof

A self-adhesive protective film, high temperature resistant technology, applied in the direction of chemical instruments and methods, adhesives, film/sheet adhesives, etc., can solve the problems of affecting the protective film, difficult to tear off, poor viscosity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

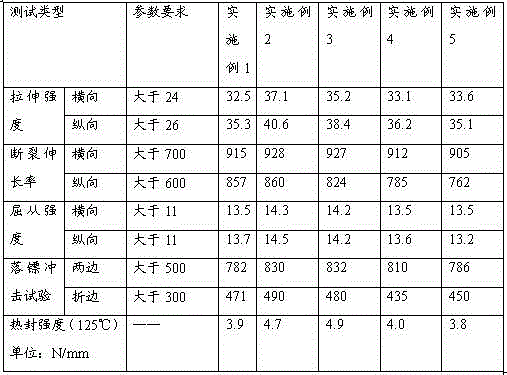

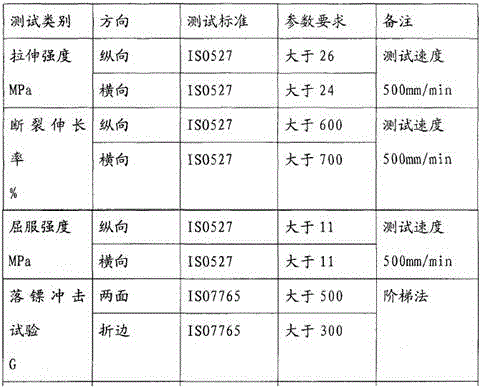

Examples

Embodiment 1

[0029]Get 80 parts of Metocene-EM248U metallocene polypropylene low-density elastomer produced by Basell Company, 5 parts of LDPE-LD600BA low-density polyethylene produced by Exxon Mobil, and 15 parts of SEBS-A1536H SEBS produced by American Kraton as the protective film. Adhesive layer resin; take 85 parts of HDPE-HD 8660.29 high-density polyethylene produced by ExxonMobil and 15 parts of LDPE-LD600BA low-density polyethylene produced by ExxonMobil as the middle layer resin of the protective film; take ExxonMobil 80 parts of MDPE-MD3505CH medium-density polyethylene produced, and 20 parts of LDPE-LD600BA low-density polyethylene produced by Exxon Mobil were used as the middle layer resin of the protective film as the back material layer resin of the protective film.

[0030] Among them, in terms of the mass percentage of the raw materials of each layer in the entire protective film, the self-adhesive layer, the middle layer and the back material layer are 5%, 80% and 15% respe...

Embodiment 2

[0033] Take 70 parts of Metocene-EM248U metallocene polypropylene low-density elastomer produced by Basell, 10 parts of LDPE-LD600BA low-density polyethylene produced by Exxon Mobil, and 20 parts of SEBS-A1536H SEBS produced by American Kraton as the protective film. Adhesive layer resin; take 80 parts of HDPE-HD 8660.29 high-density polyethylene produced by ExxonMobil and 20 parts of LDPE-LD600BA low-density polyethylene produced by ExxonMobil as the middle layer resin of the protective film; take ExxonMobil 75 parts of MDPE-MD3505CH medium density polyethylene produced and 25 parts of LDPE-LD600BA low density polyethylene produced by Exxon Mobil were used as the middle layer resin of the protective film as the back material layer resin of the protective film.

[0034] Among them, in terms of the mass percentage of the raw materials used in each layer in the entire protective film, the self-adhesive layer, the middle layer and the back material layer are 10%, 70% and 20% respe...

Embodiment 3

[0037] Take 70 parts of Metocene-EM248U metallocene polypropylene low-density elastomer produced by Basell, 10 parts of LDPE-LD600BA low-density polyethylene produced by Exxon Mobil, and 20 parts of SEBS-A1536H SEBS produced by American Kraton as the protective film. Adhesive layer resin; take 80 parts of HDPE-HD 8660.29 high-density polyethylene produced by ExxonMobil and 20 parts of LDPE-LD600BA low-density polyethylene produced by ExxonMobil as the middle layer resin of the protective film; take ExxonMobil 70 parts of MDPE-MD3505CH medium density polyethylene produced and 30 parts of LDPE-LD600BA low density polyethylene produced by Exxon Mobil were used as the middle layer resin of the protective film as the back material layer resin of the protective film.

[0038] Among them, in terms of the mass percentage of the raw materials used in each layer in the entire protective film, the self-adhesive layer, the middle layer and the back material layer are 20%, 70% and 10% respe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com