Metal sheet profiled proton exchange membrane fuel cell bipolar plate

A proton exchange membrane and thin metal plate technology, applied in solid electrolyte fuel cells, fuel cells, fuel cell components, etc., can solve the problems of increasing assembly processes, assembly errors, increasing the weight of bipolar plates, etc., and achieve improved sealing performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: this embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following the described embodiment.

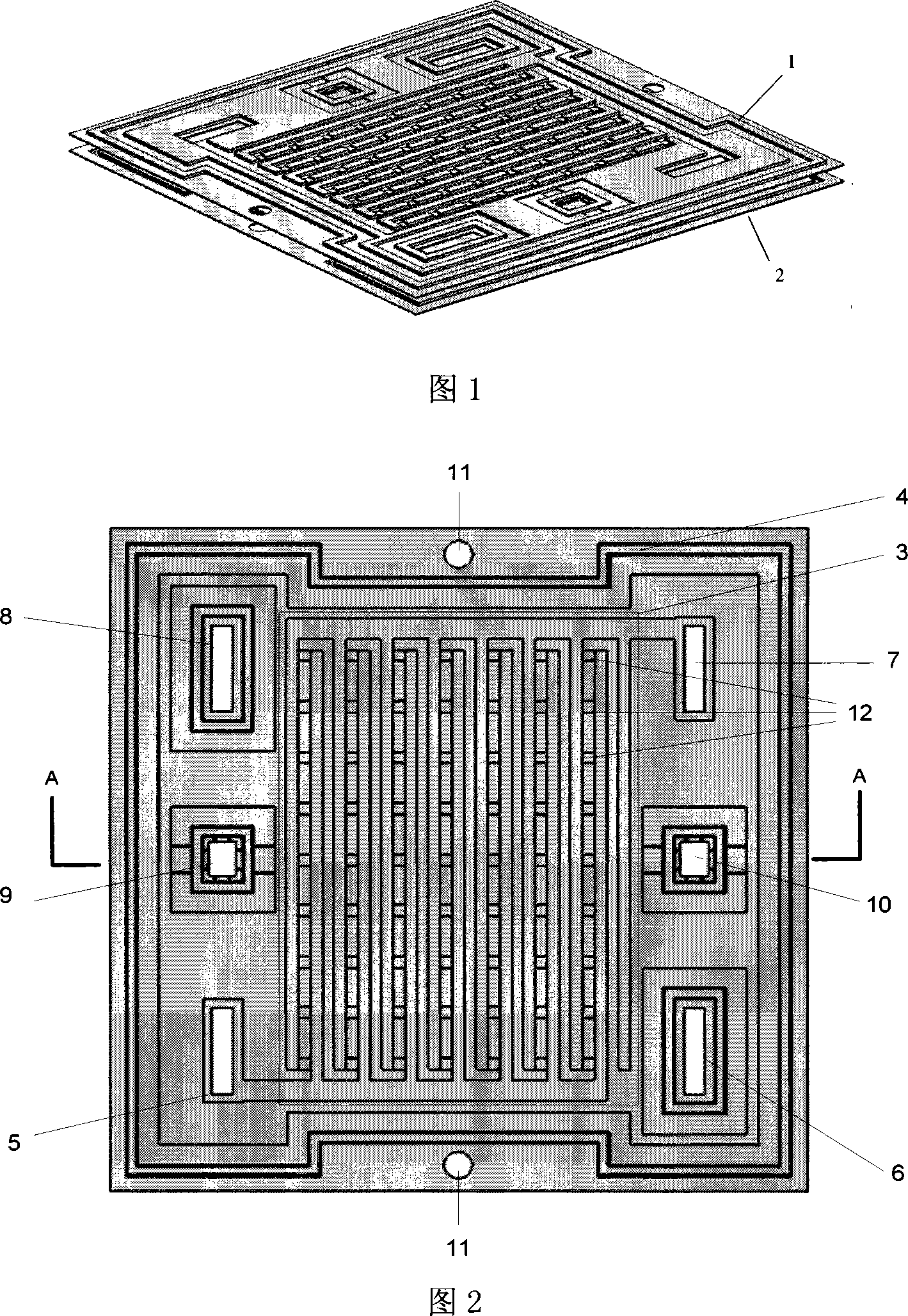

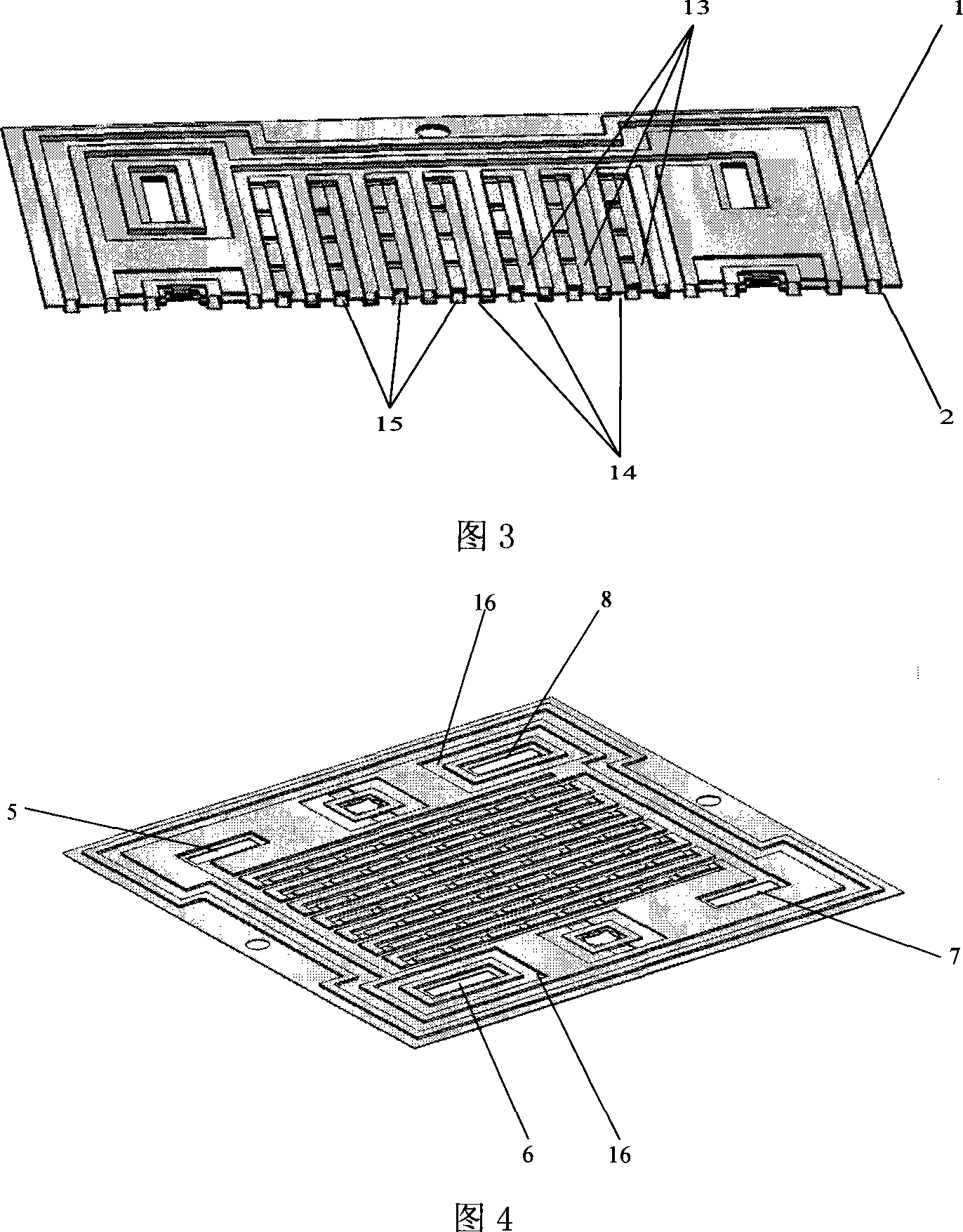

[0017] Figure 1 is a schematic diagram of the overall structure, including two identical flow field veneers 1 and 2. The entire plate structure is almost completely symmetrical, and can be formed by one stamping under a set of molds, which are respectively used as the cathode and anode of the bipolar plate.

[0018] As shown in Figure 2, it is the front view of the flow field veneer. The middle area of the flow field veneer is the reaction flow field 3, which adopts the improved straight flow channel interdigitated flow field, and the cross section of the flow chann...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com