Measuring system and measuring method of mass, center of mass and moment of inertia of rigid body

A moment of inertia and measurement system technology, which is applied in the field of measurement, can solve problems such as cycle lengthening, measurement cycle error, and poor accuracy of moment of inertia, and achieve the effects of easy installation and disassembly, removal of accidental errors, and high action accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046]In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

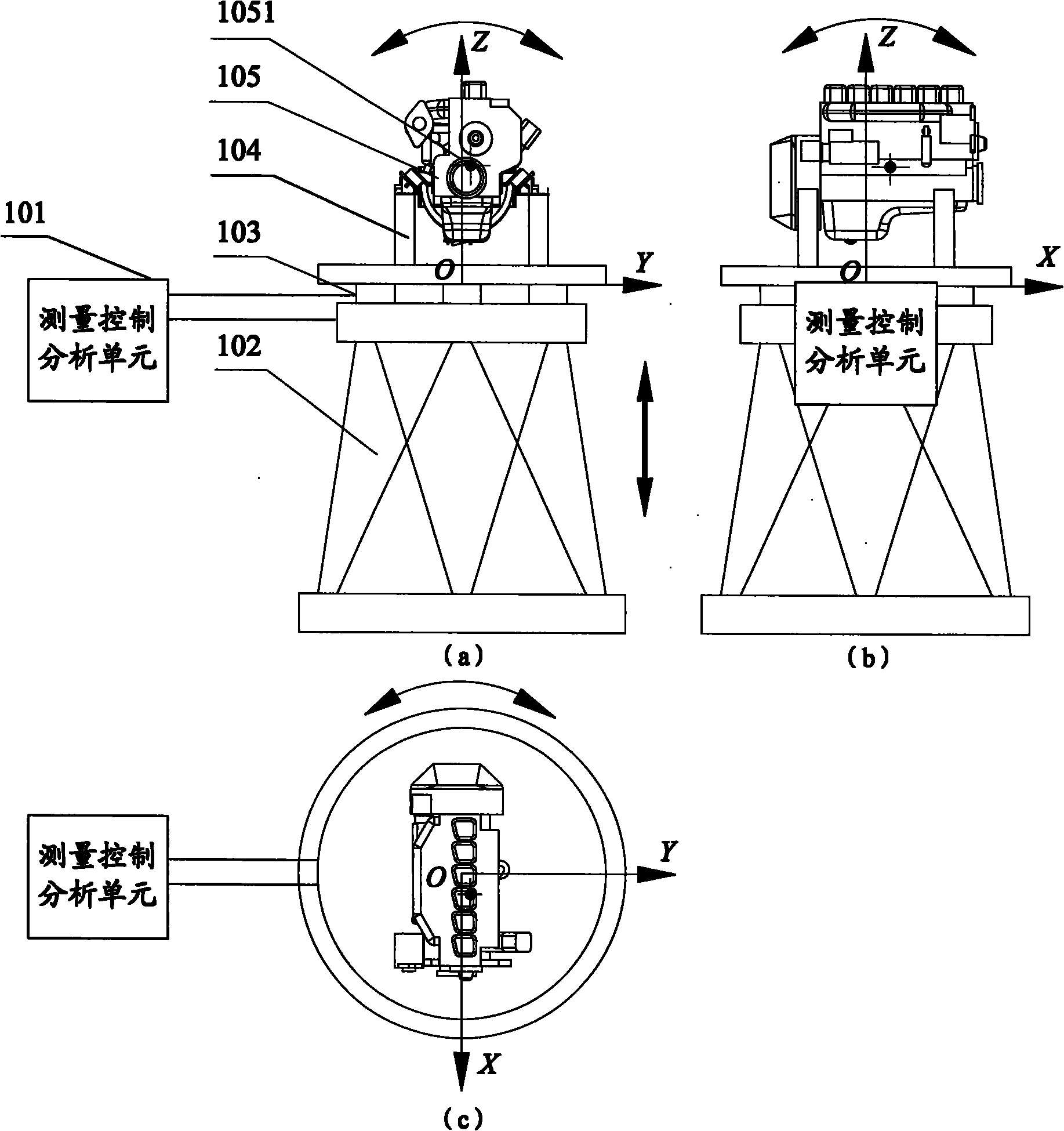

[0047] refer to figure 1 , which shows a structural schematic diagram of an embodiment of a measurement system for the mass, center of mass and moment of inertia of a rigid body of the present invention, wherein the measurement system includes:

[0048] The measurement control analysis unit 101 is used to control the posture or motion mode of the six-degree-of-freedom motion platform by sending motion signals, and analyze and calculate the measured rigid body according to the motion signals and the force and torque transmitted by the six-component force sensor. 105 mass, center of mass and moment of inertia;

[0049] The six-degree-of-freedom motion platform 102 is used to move according to the corresponding posture or motion mode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com