Simulation experimental pipeline device and simulation experimental method of multi-phase fluid erosion and flow states

A simulation experiment and multi-phase flow technology, applied in the direction of measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve the problems that cannot truly reflect the flow characteristics of the flow pipeline, avoid edge effects, and be easy to disassemble and install Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

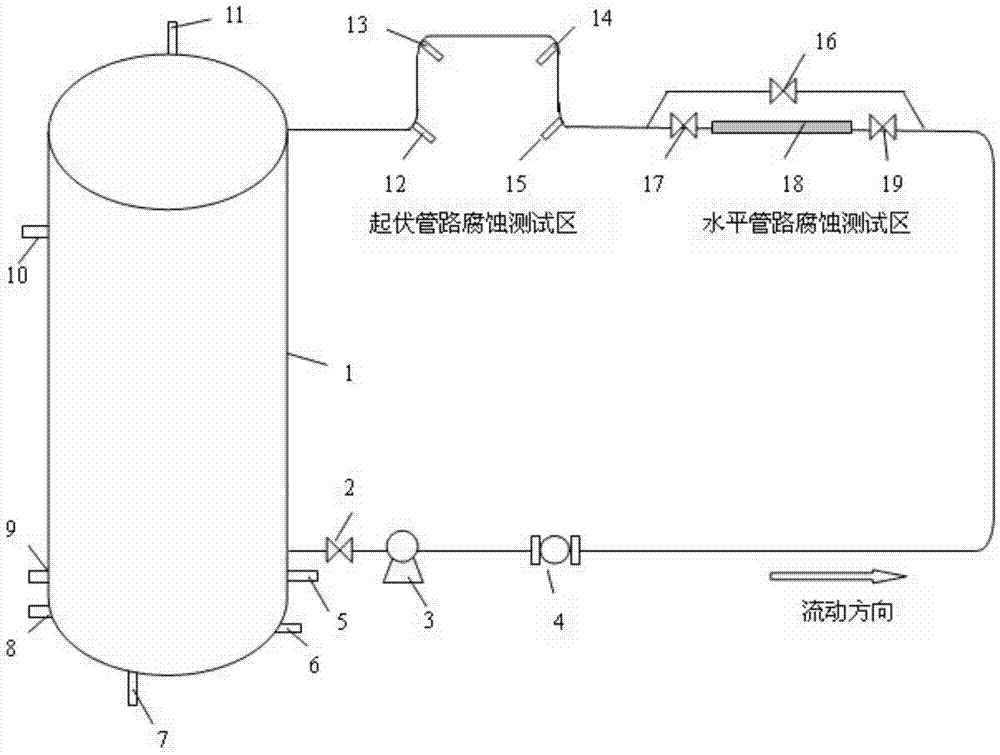

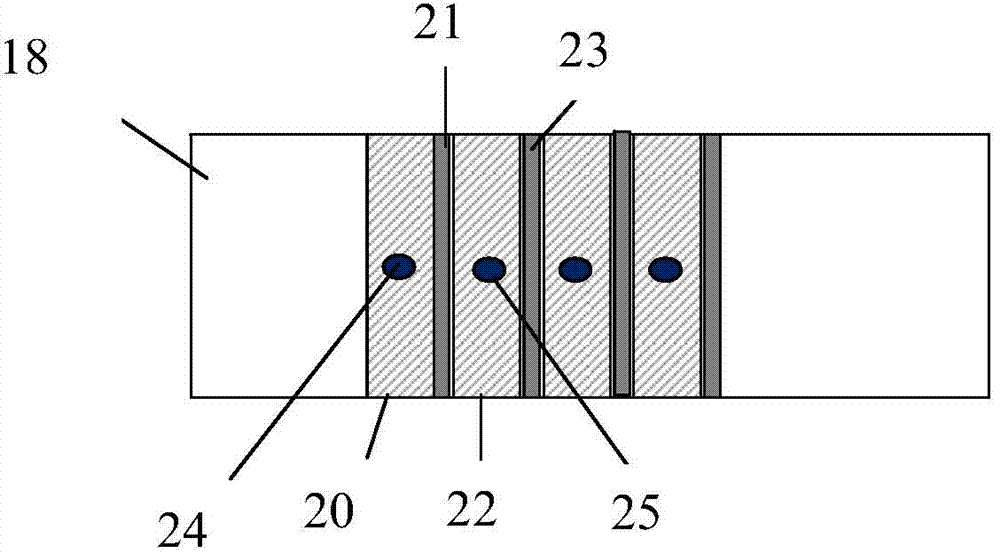

[0031] The invention provides a pipeline device for multiphase flow corrosion and flow state simulation experiments, which includes pipelines, supports, corrosion-resistant storage tanks, corrosion-resistant pumps, ball valves, electromagnetic flowmeters, resistance probes, thermometers, pH meters, Dissolved oxygen meter, high-speed camera, the pipeline includes undulating pipeline corrosion test area and horizontal pipeline corrosion test area.

[0032] A resistance probe is installed at each inclination of the undulating pipeline corrosion test area for real-time monitoring of corrosion behavior at different inclination angles, and the resistance probe is set flush with the pipe wall of the pipeline.

[0033] There is a gas inlet at the bottom of the corrosion-resistant storage tank, a gas outlet at the top, an experimental liquid inlet on the upper side wall of the corrosion-resistant storage tank, and an experimental liquid outlet on the lower side wall. The gas inlet and g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com