Prefabricated bridge abutment multifunctional lifting system and construction procedure thereof

A multi-functional, prefabricated pier technology, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of increasing on-site construction volume, unfavorable use of position adjustment equipment turnover, etc., to improve stability and increase equipment turnover utilization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments to facilitate a clear understanding of the present invention, but they do not limit the present invention.

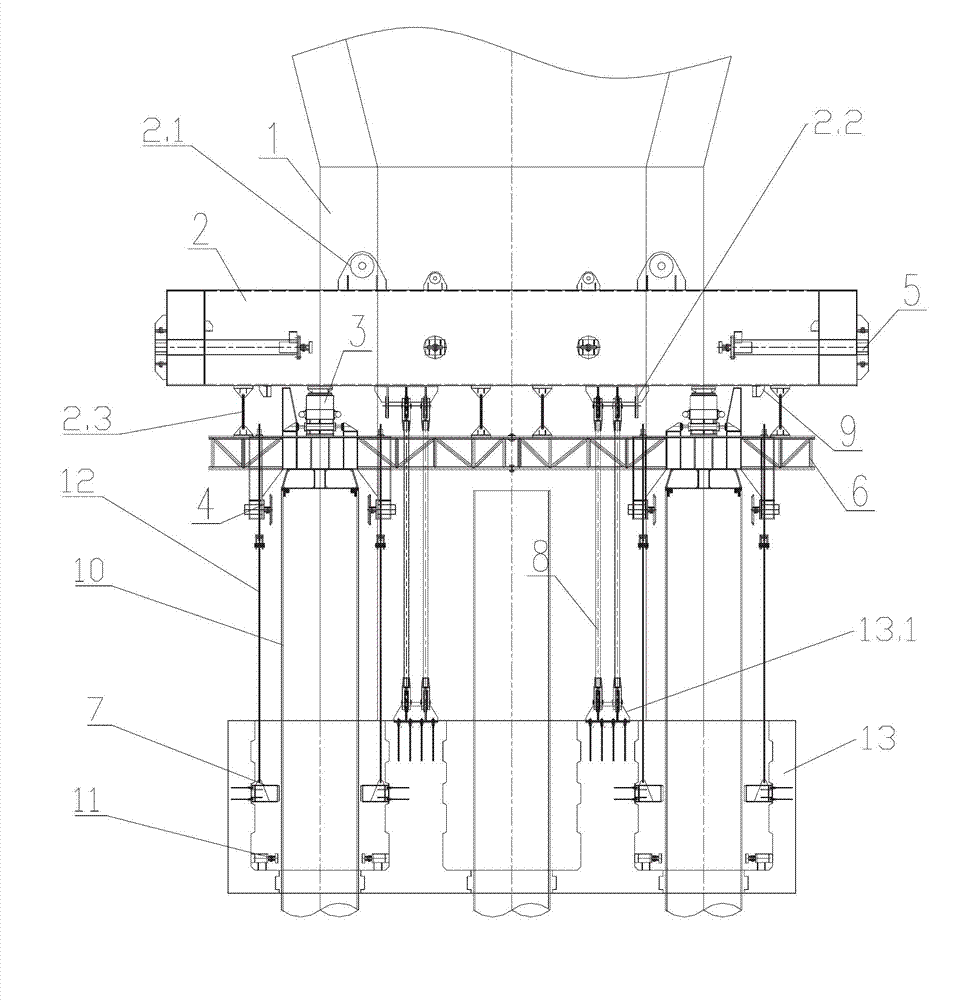

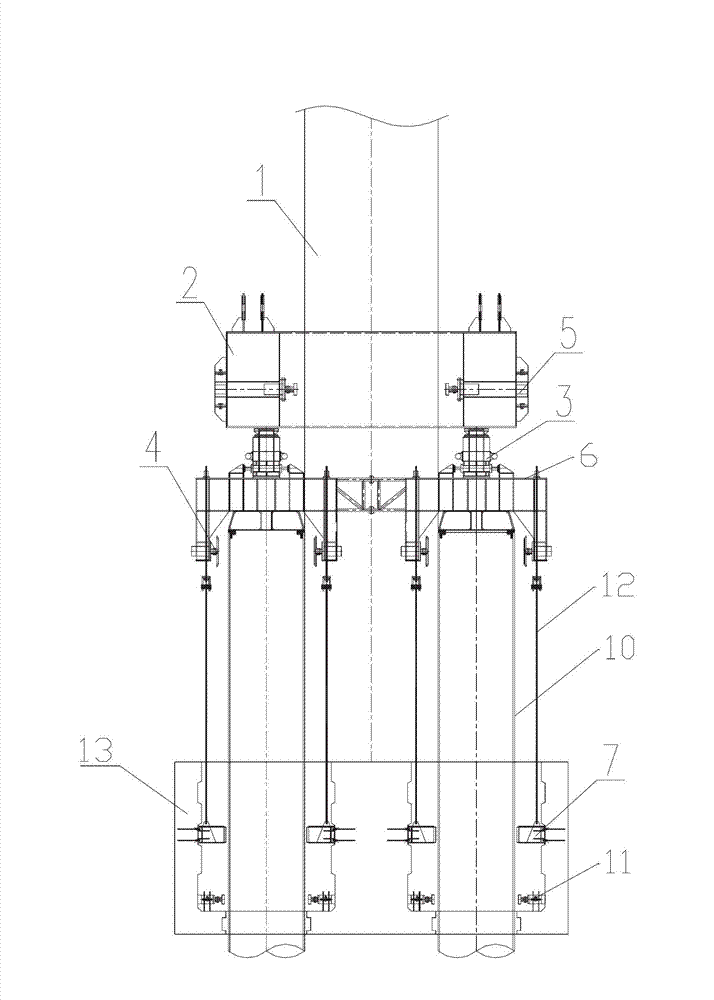

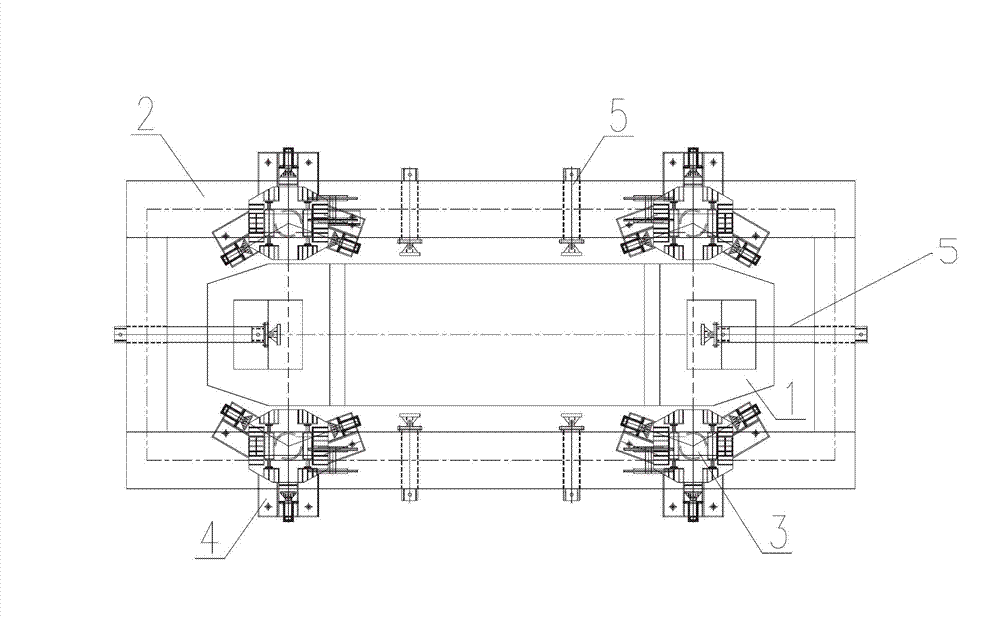

[0024] As shown in the figure, a bridge prefabricated abutment multifunctional hoisting system, which includes a hoisting structure 2 for hoisting the prefabricated abutment 1 and a positioning mechanism 3 for three-way adjustment of the prefabricated abutment 1, hoisting Mechanism 2 is connected to supporting truss 6 through flexible sling 2.3, position adjustment mechanism 3 is set between supporting truss 6 and hoisting mechanism 2, supporting truss 6 is fixed on steel pipe pile 10, and steel pipe pile 10 passes through the prefabricated The inner hole of bearing platform 13 is specifically:

[0025] The hoisting structure 2 is a hollow box structure, the prefabricated abutment 1 is fixed in the hoisting structure 2, the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com