Cantilever construction detachable triangle hanging basket load-bearing primary truss

A triangular hanging basket, detachable technology, applied in the direction of erecting/assembling bridges, bridges, buildings, etc., can solve the problems of difficult equipment monitoring, inconvenient long-distance transportation, easy loss, etc., to save material and labor costs, Easy to assemble and transport, and improve the effect of mechanical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

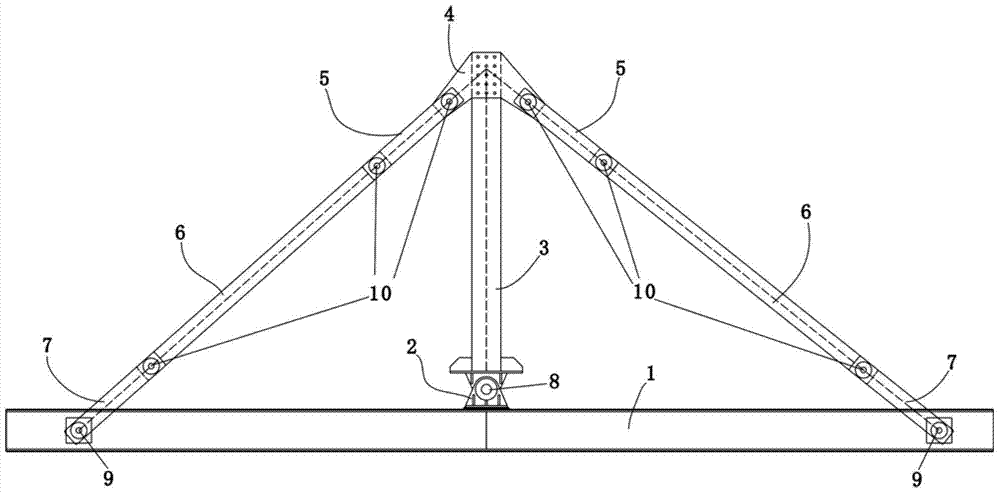

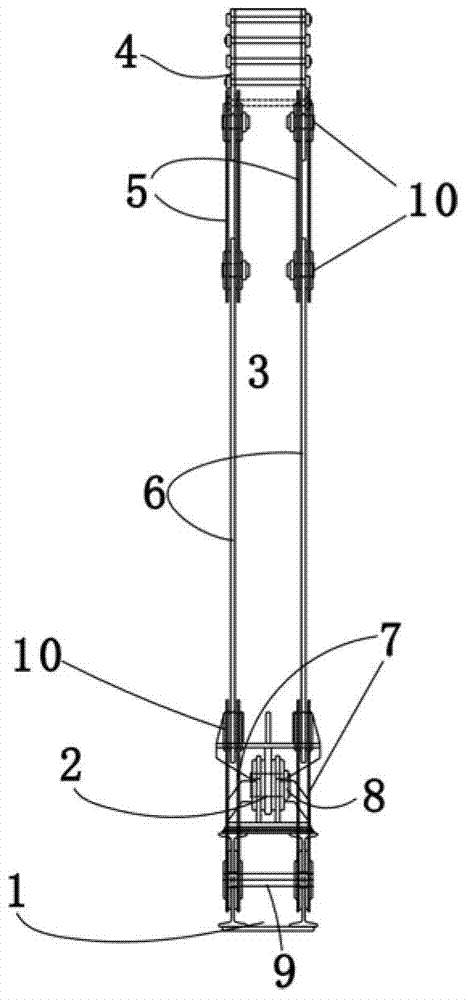

[0035] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0036] see figure 1 , 2 In this embodiment, the cantilever construction dismountable triangular hanging basket load-bearing main truss includes a main beam 1 composed of double I-beams, a hinged adjustable base 2, a column 3 assembled with channel steel, a plate-type connection column head 4, and a The front and rear oblique tie rods 5, 6, and 7 formed by pulling 16Mn steel belts (the single oblique tie rod on each side is composed of 2 No. 5 steel belts, 1 No. 6 steel belt and 2 No. 7 steel belts, among which, The specification of No. 6 steel strip is generally 200mm×21mm, the specification of No. 5 and No. 7 steel strips is generally 200mm×12mm), and No. 45 steel pins 8, 9 and 10 are subjected to shear and pressure.

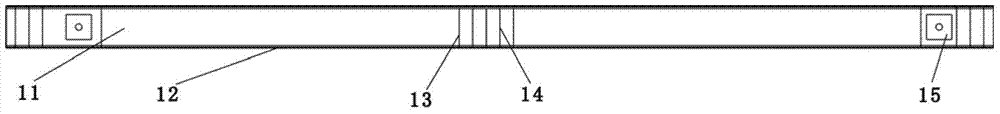

[0037] Such as Figure 3a , 3b As shown, the main girder 1 includes two I-beams 11 arranged in parallel. can change t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com