Folding drawing steel internal mould system for prefabricated hollow beam

A pull-type, hollow beam technology, applied in the direction of ceramic molding core, ceramic molding mandrel, etc., can solve the problems of easy corrosion and damage of bamboo plywood, high use cost, low turnover rate, etc., and achieve self-heavy, turnover utilization rate High, improve the effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

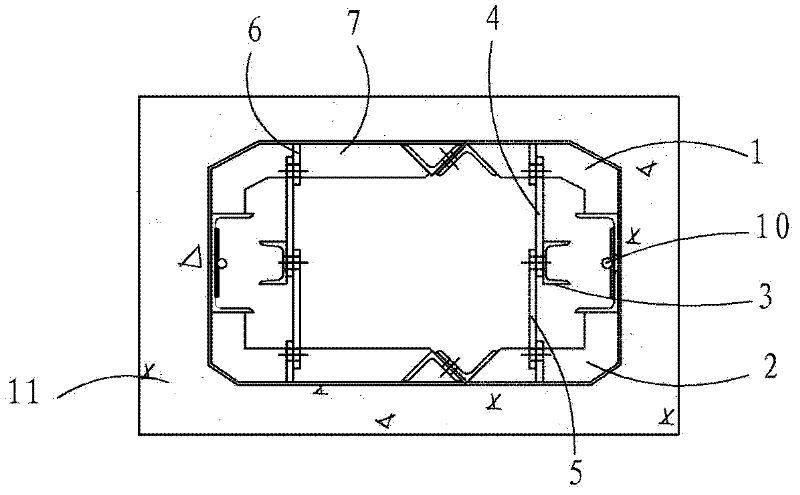

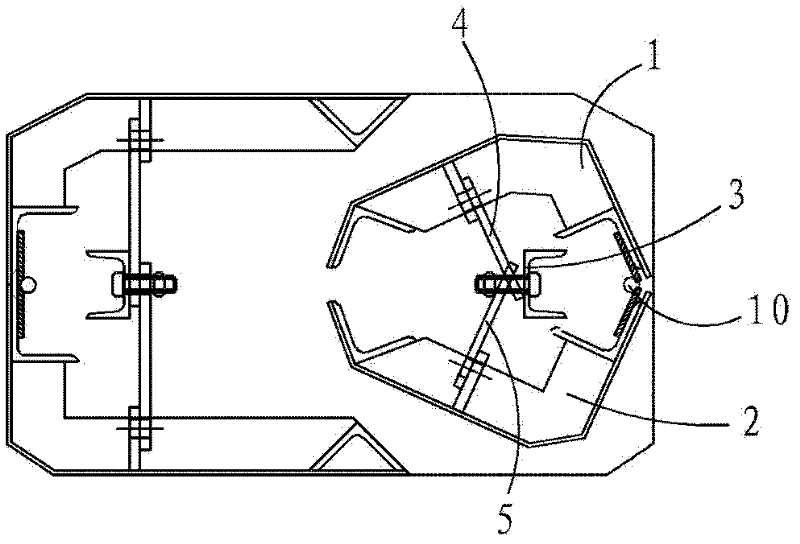

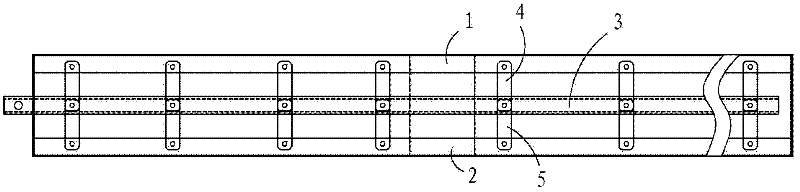

[0029] see figure 1 and image 3 , the prefabricated hollow beam folding and pulling steel inner mold system in this embodiment adopts a steel structure, and on the cross section of the inner mold, two half-mould units with opposite openings are arranged in a left and right split; each half-mould unit The upper unit plate 1 and the lower unit plate 2 are respectively hinged at the sides to form a hinge structure that can be expanded or folded up and down;

[0030] In each half-mould unit, tie rods 3 are arranged along the length direction of the inner mold, and the tie rods 3 are hinged with the upper unit plate 1 at the position of the top plate with a set of upper connecting rods 4 arranged at intervals, and a set of lower connecting rods arranged at intervals 5 is hinged with the lower unit plate 2 at the position of the bottom plate;

[0031] With the structure in this embodiment, the inner mold can have the following two states by operating the pull rod 3:

[0032] fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com