Material guiding cover structure suitable for air-flowing type dryer feeding airlock

An airflow drying and material hood technology, which is applied in the direction of drying solid materials, tobacco drying, drying, etc., can solve the problems of laborious handling, small space, and large maintenance force, and achieve the effect of simple operation and improved automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

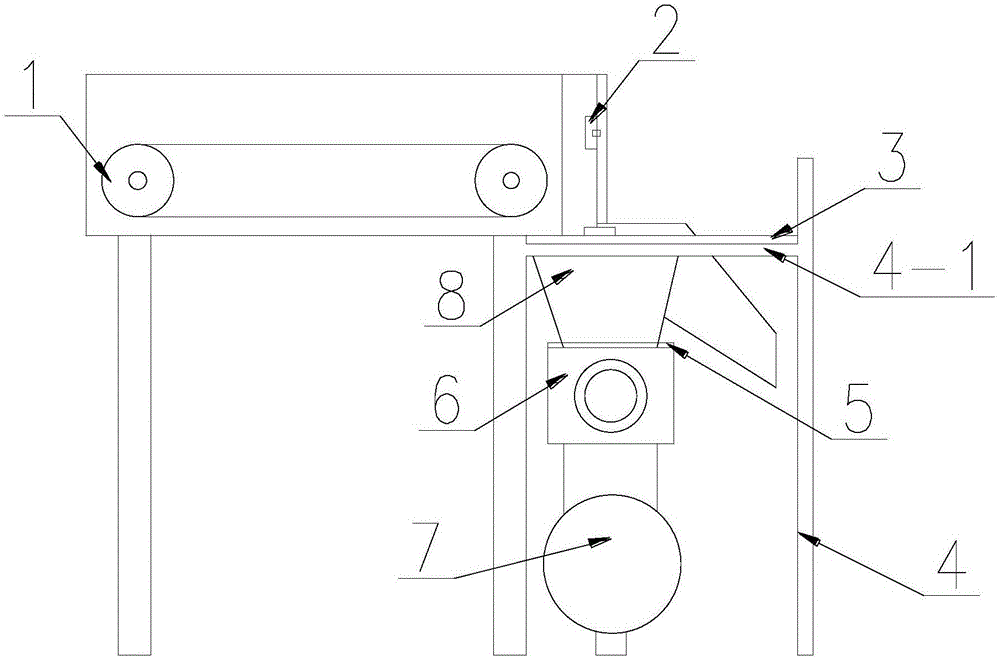

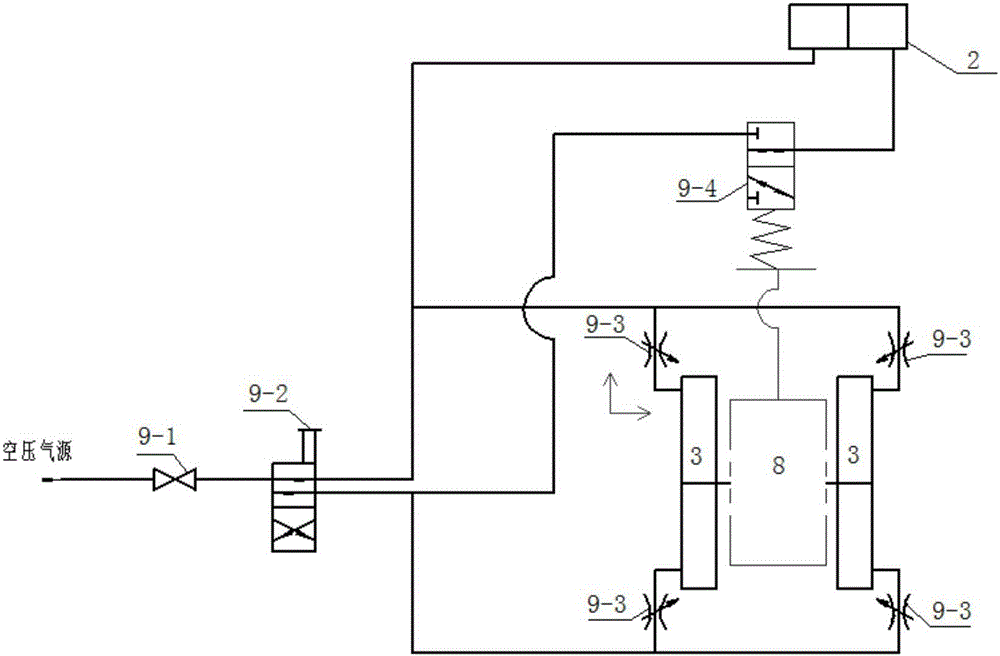

[0035] Example: such as figure 1 As shown, a material guide cover structure suitable for the feed airlock of the airflow dryer, including:

[0036] Feeding and metering belt mechanism 1, one side of the feeding and metering belt mechanism is the discharge port;

[0037] Below the outlet is the feed air lock 6, and the lower part of the feed air lock 6 communicates with the sublimation tube 7;

[0038] The outer side of the discharge port is provided with a movable guide cover bracket 4;

[0039] There is a parallel support part 4-1 on the mobile material guide cover bracket, and a sliding mechanism is installed on the upper side of the parallel support part 4-1, and the sliding mechanism makes the material guide cover 8 guide the material from the feed metering belt mechanism 8 to the feed air lock .

[0040] According to different requirements, the sliding mechanism can be optionally a linear slide table. As a preferred solution, the sliding mechanism is selected as the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com