Movable formwork supporting truss and construction method thereof

A technology for supporting trusses and moving formwork, which is applied to the preparation of formwork/formwork/work frames, pillars, and building components on site. It can solve the problems of low utilization rate, failure to turn around the frame pipes in time, and increase construction costs. Achieve the effect of saving manpower and material resources and considerable economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

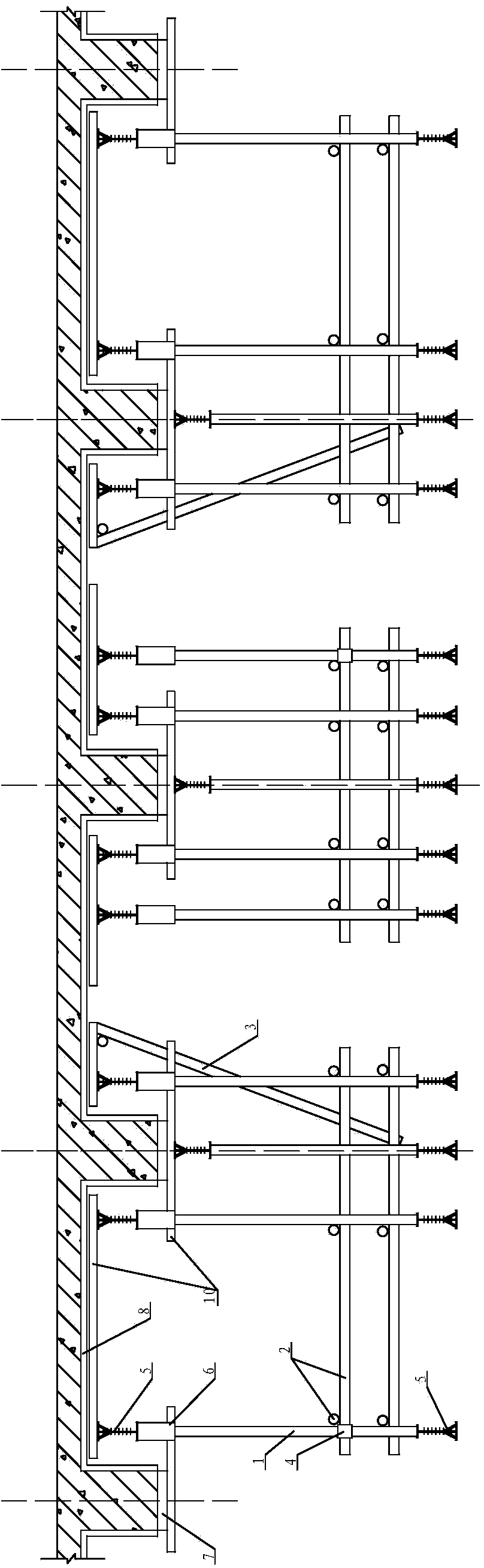

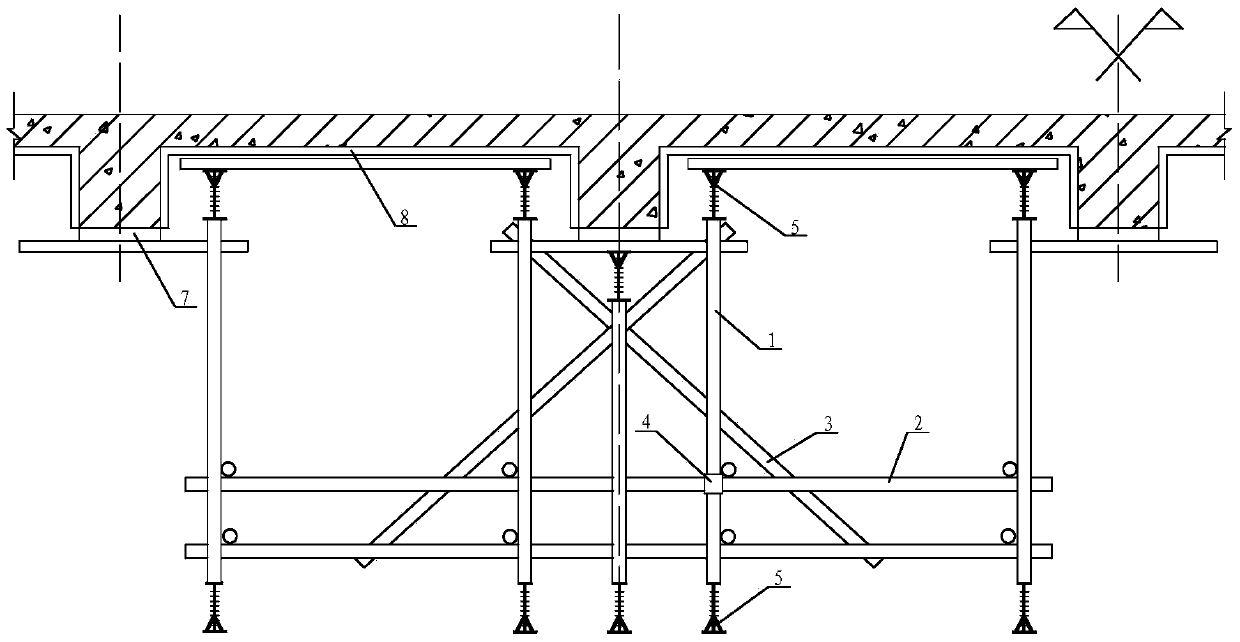

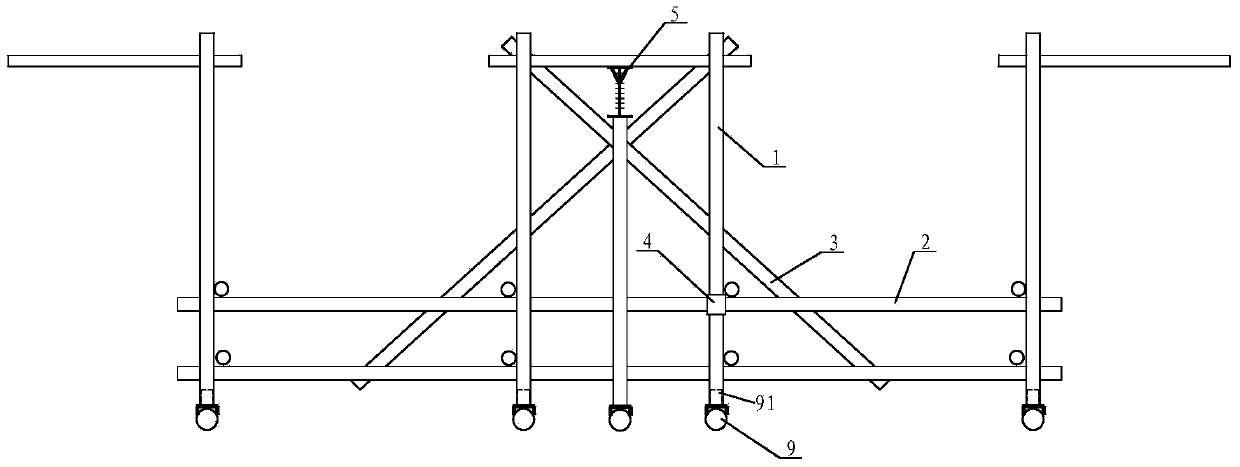

[0046] In this embodiment, the supporting rods are all made of 48mm×3.5mm steel pipes, and the connecting fasteners 4 are used to connect each rod. The top of the vertical rod 1 is connected, and the two ends and the middle position of the diagonal brace 3 are connected and fixed with the vertical rod 1 by the fastener 4.

[0047] The connecting fastener 4 is a fastener commonly used in construction. Among them, the right angle fastener (cross buckle) is used for the connection of two vertically intersecting steel pipes; the rotary fastener (swivel buckle) is used for the connection of two cross steel pipes at any angle; the butt joint fastener (one-word buckle) is used for two Steel pipe butt connection. A stable supporting truss that forms a fixed unit according to the size of the roof beam slab structure to be constructed.

[0048] The steel casing 6 is a Φ63 steel pipe, and an inner baffle 61 is arranged on the inner side of its lower part. The inner baffle 61 is an annu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com