Construction method for dynamic steel supporting system of deep foundation pit

A construction method and steel support technology, which can be applied in basic structure engineering, excavation, construction, etc., can solve the problems of reducing time effect and a large amount of steel, and achieve the effect of saving usage, reasonable force, and speeding up construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

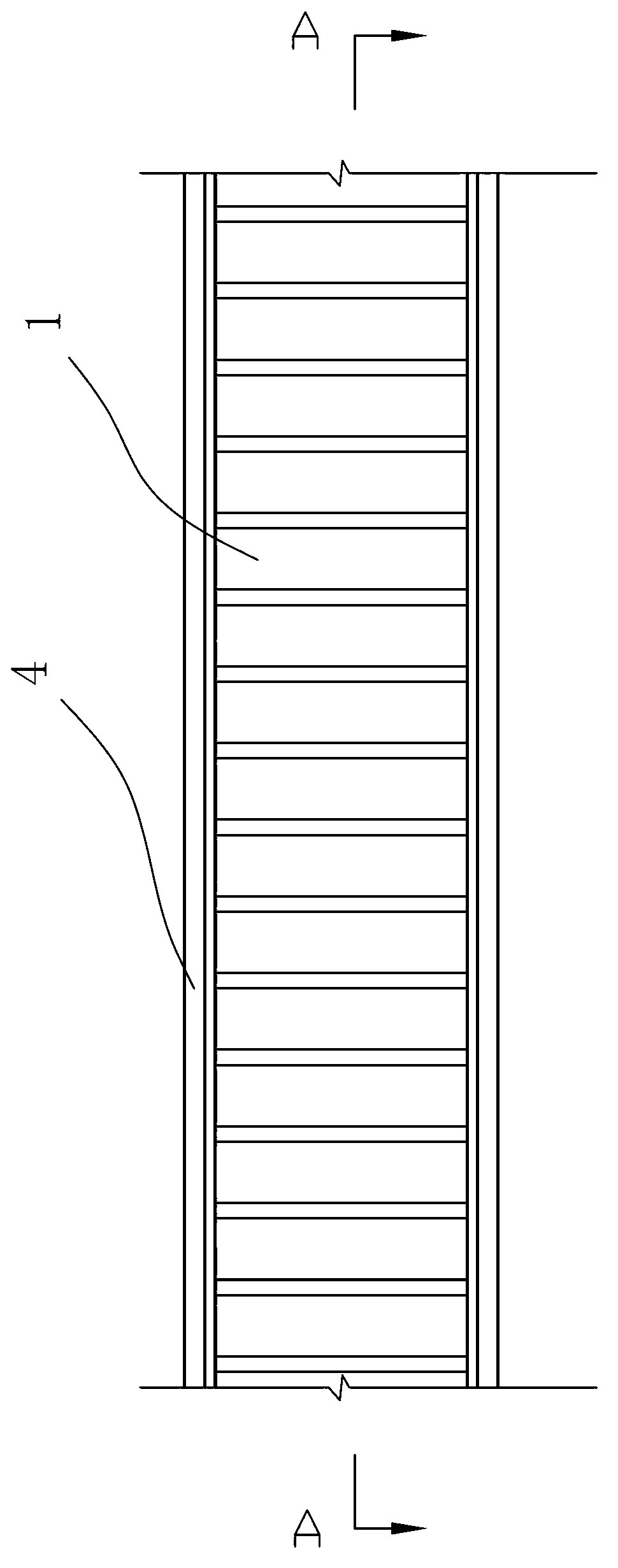

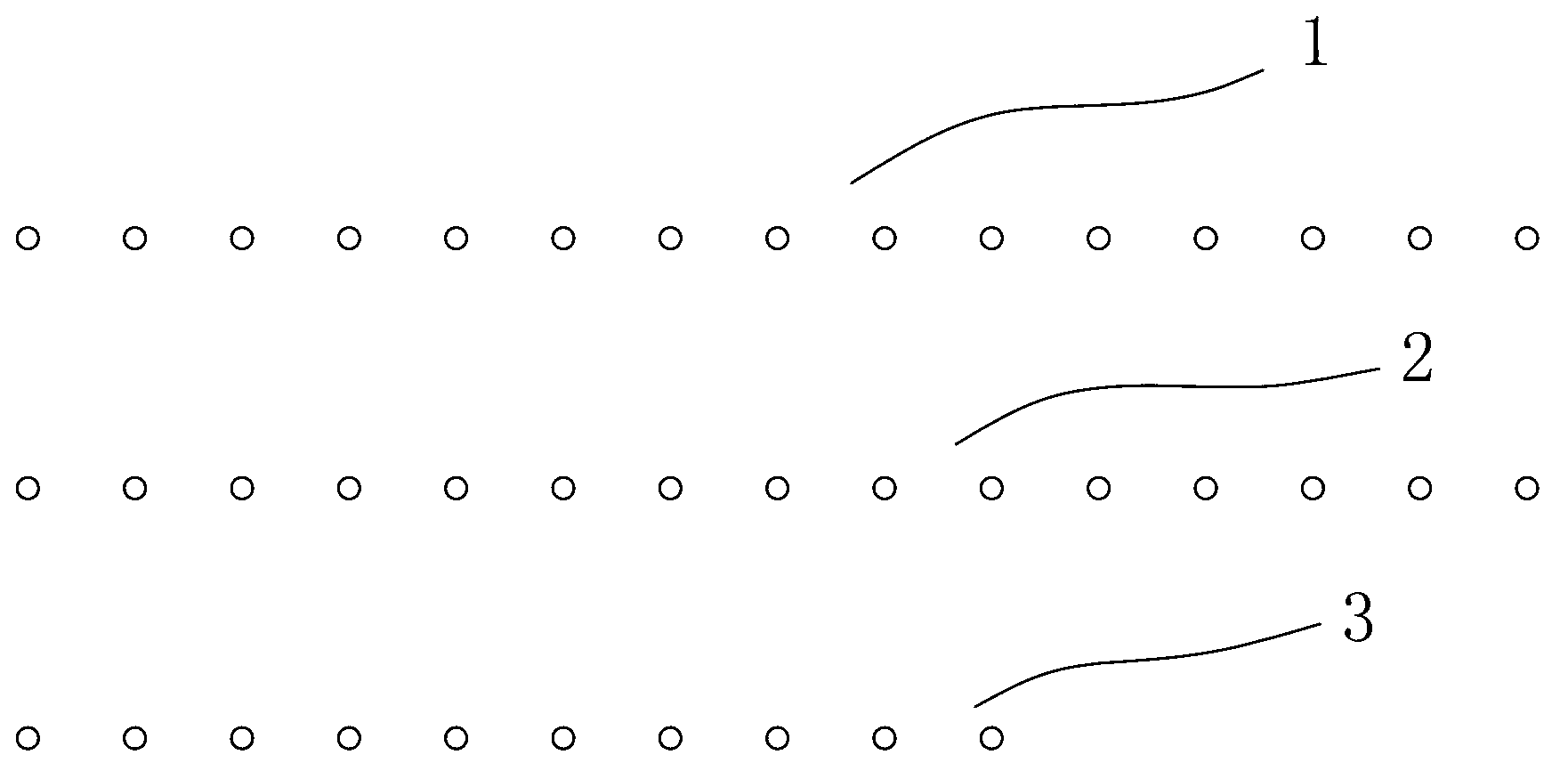

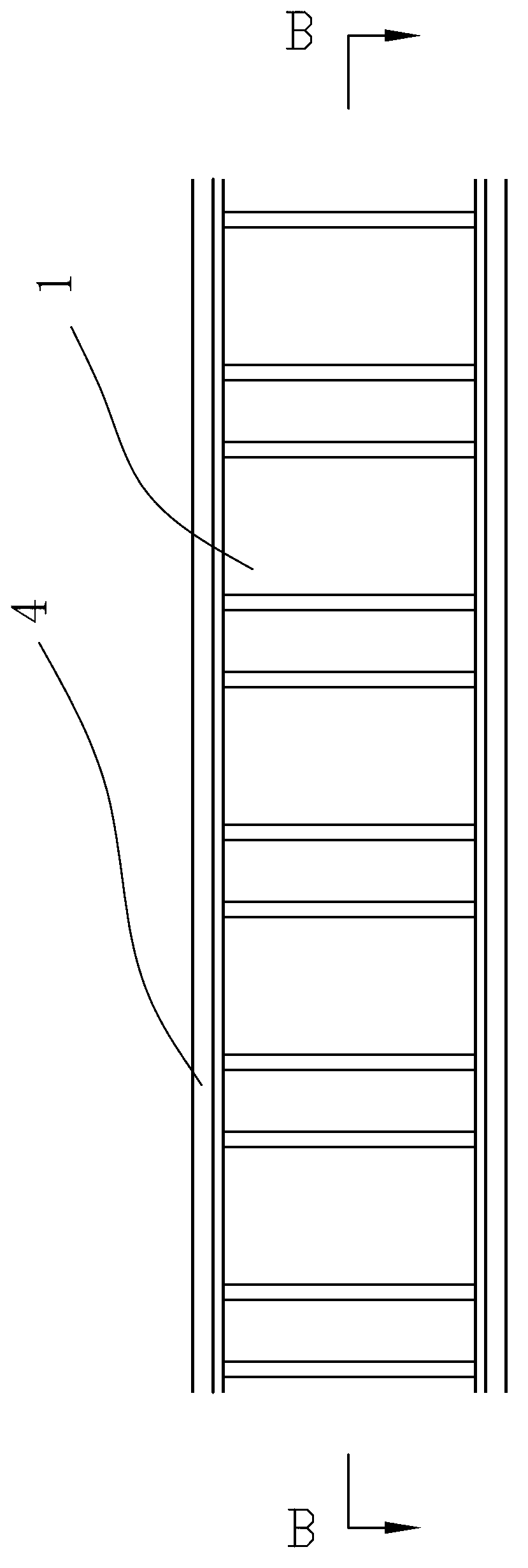

[0019] refer to Figure 1 to Figure 4 , the construction method of a deep foundation pit dynamic steel support system of the present invention comprises the following steps:

[0020] 1) Construct foundation pit enclosure structure 4;

[0021] 2) Excavate the first layer of earthwork in the foundation pit enclosure structure, and install the first layer of steel support 1;

[0022] 3) Excavate the second layer of earth and install the second layer of steel support 2;

[0023] 4) Excavate the third layer of earth and install the third layer of steel support 3;

[0024] 5) According to the design requirements, remove several steel supports from the first layer of steel supports 1 and / or the second layer of steel supports 2 and install them into the third layer of steel supports 3 synchronously.

[0025] When using layered excavation method to excavate the foundation pit, when the next layer of earthwork is excavated and steel support is installed, the stress on the steel suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com