Modular prefabricated concrete circular arc chamfering waterproof system for waterproof paving of roofing coils and construction method of modular prefabricated concrete circular arc chamfering waterproof system

A prefabricated concrete, arc chamfering technology, applied in the direction of roof, roof covering, roof insulation material, etc. Good visual effect, simple installation, not easy to empty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

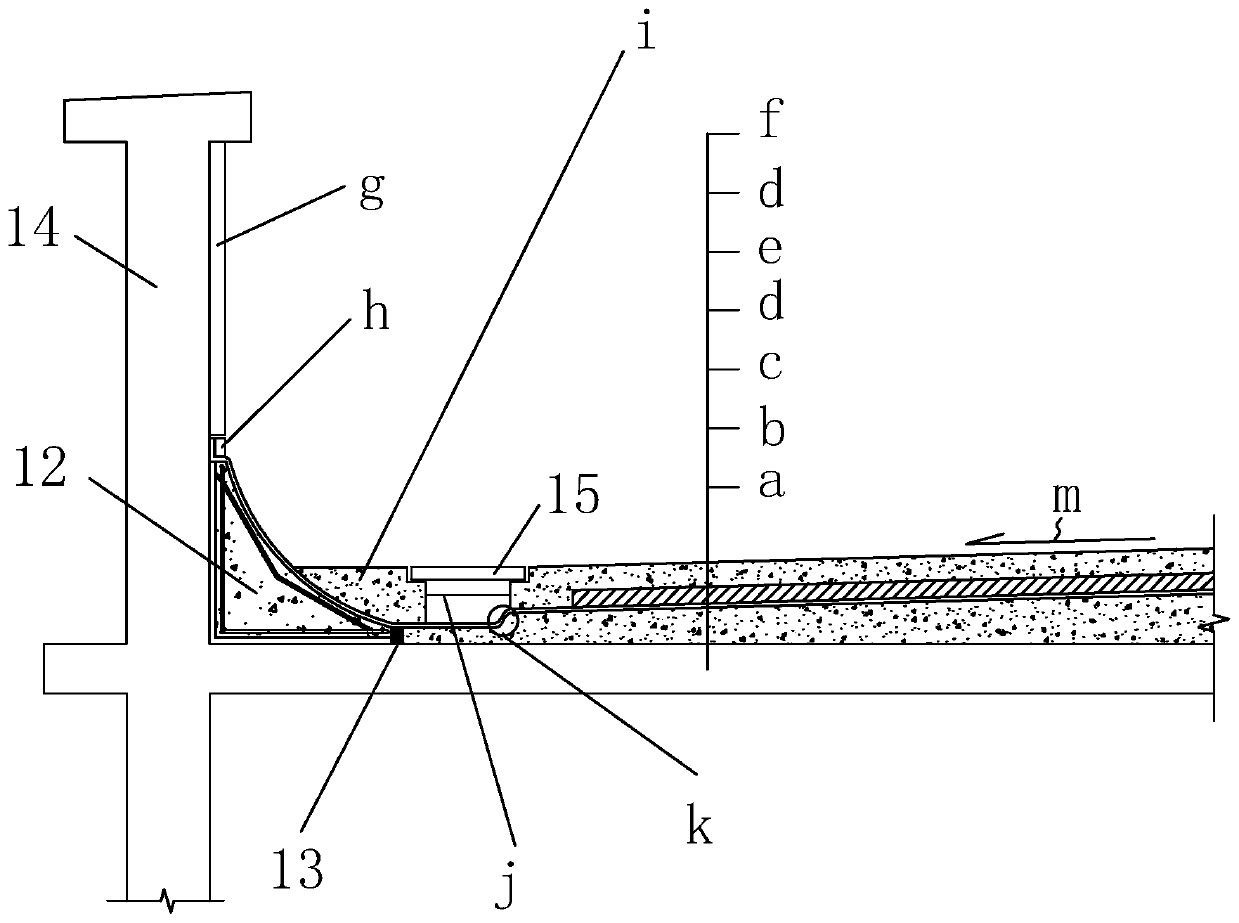

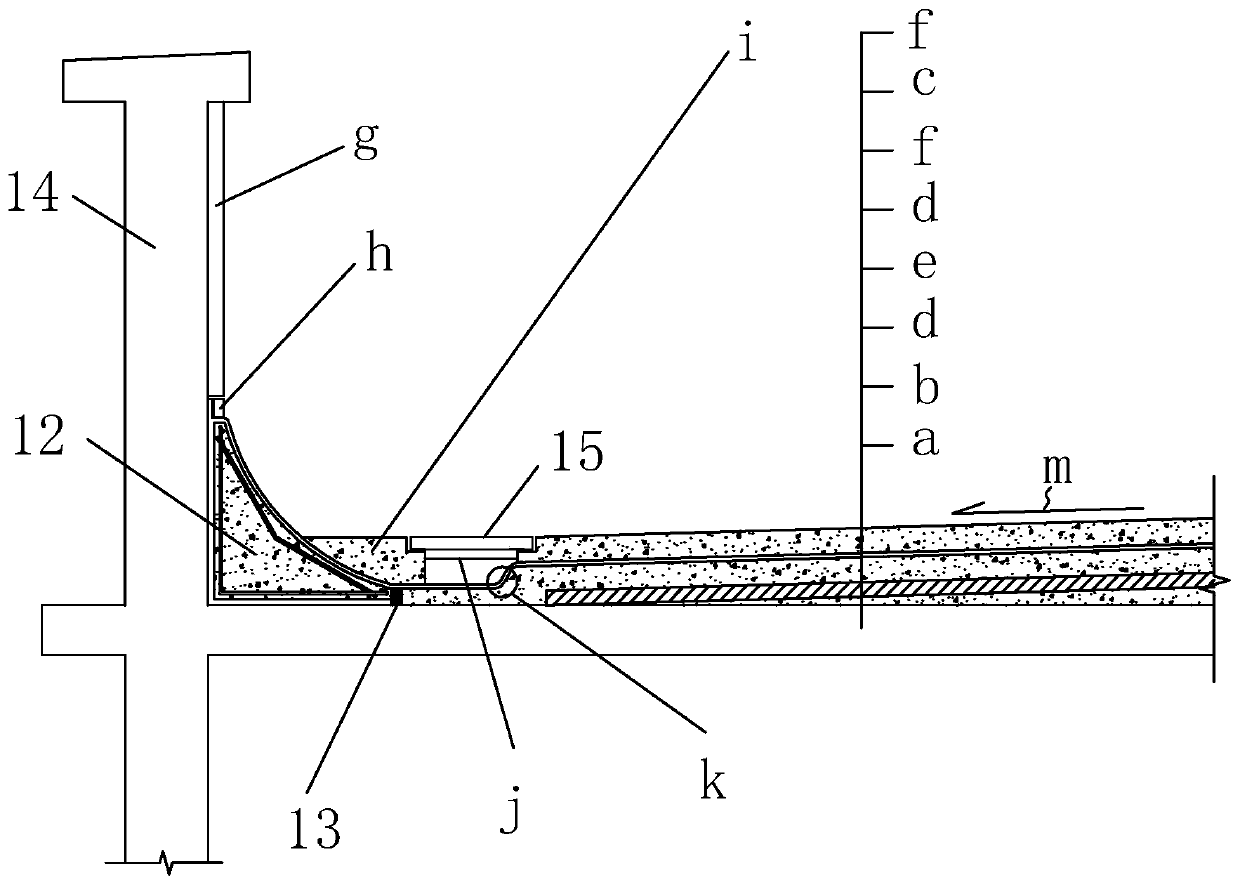

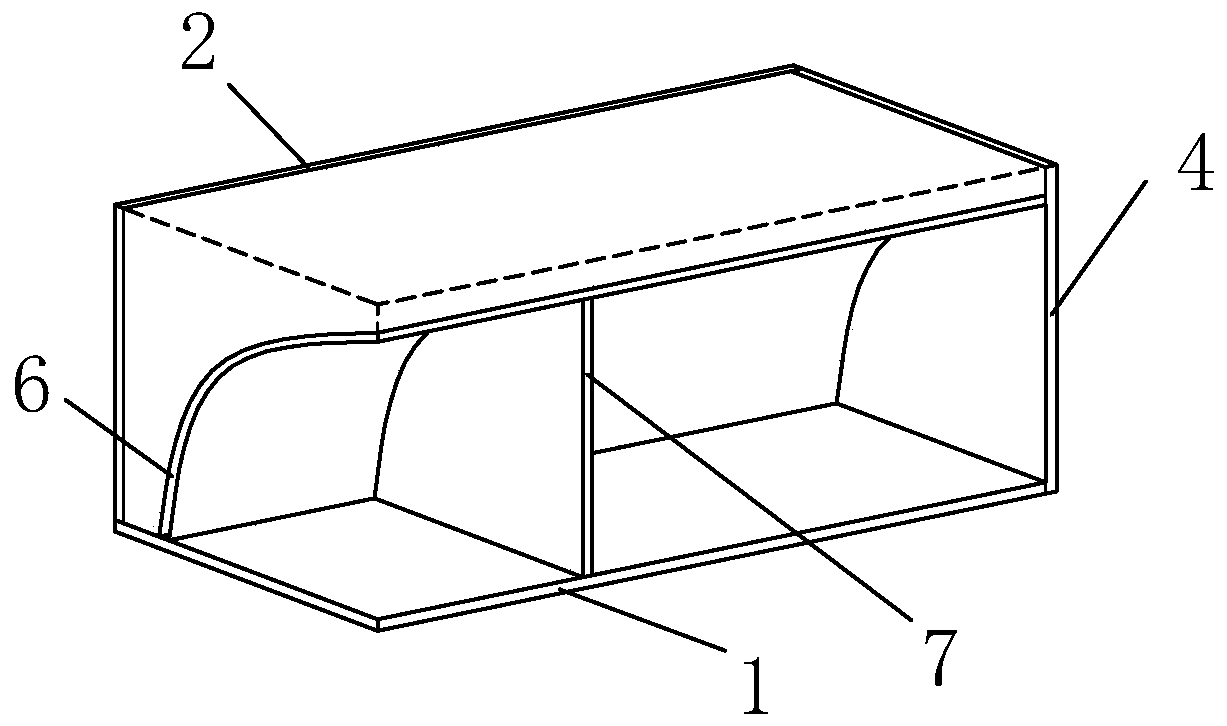

[0057] A modular prefabricated concrete circular arc chamfering waterproof system for roofing membrane waterproof paving, applied to the corner of the junction of the roof parapet and the roof panel, the waterproof system comprises a plastering layer arranged on the roof parapet g and the leveling layer, thermal insulation layer, isolation layer, protective layer and waterproof layer arranged on the construction roof panel; the waterproof layer (that is, the waterproofing membrane layer) can be arranged under the thermal insulation layer or on the thermal insulation layer; when When the waterproofing membrane is placed under the insulation layer, see figure 1 Schematic diagram of the structure, on the construction roof structure layer a from bottom to top are the fine stone concrete leveling layer b, the waterproof layer c, the polyethylene film isolation layer d, the thermal insulation layer e, the polyethylene film isolation layer d and the crack-resistant steel mesh. Fine s...

Embodiment 2

[0063] A construction method of a modular precast concrete arc chamfered waterproof system for roofing membrane waterproofing paving, which is a modular precast concrete circular arc for roofing membrane waterproofing paving described in Example 1 The construction method of the chamfered waterproof system, the construction process is as follows: A. The steel component processing factory prefabricates the precast concrete arc chamfering mold → B. The modular precast concrete arc chamfering is made → C. The precast concrete arc is installed Chamfer→D. Construction of roof leveling layer→E. Construction of roof waterproof layer, thermal insulation layer, isolation layer and protective layer according to design drawings and specifications→F. Construction of parapet plastering layer; among them,

[0064] Described step A, the method that steel component processing factory prefabricates precast concrete arc chamfering mould:

[0065] A1. Using BIM three-dimensional modeling technolo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com