Inclination angle column cap combined wood former in beamless connected upright post

A technology of combining wood and column caps, which is applied in the field preparation of formwork/formwork/work frame, building components, construction, etc., can solve the problems of low utilization rate of boards, difficulty in effectively fixing formwork, and leakage of concrete, etc., to achieve reduction Small planting and cutting processing workload, increased plate turnover rate, and the effect of matching the joint surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

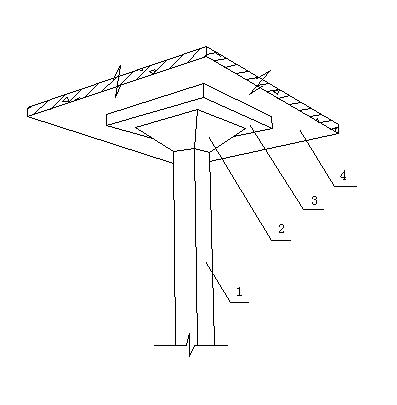

[0028] Embodiment 1 The structure and installation method of the inclined column cap wood formwork of the present invention

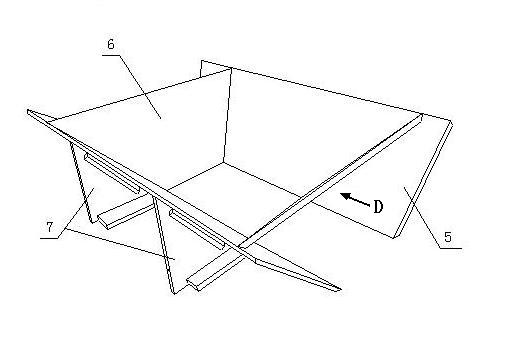

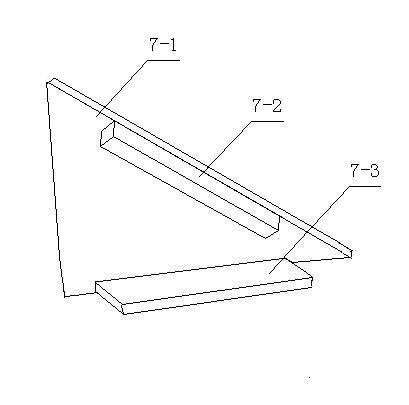

[0029] The wooden formwork structure of the inclined column cap is as follows figure 2 As shown, it is composed of trapezoidal wooden formwork 6 and two column cap rectangular wooden formwork 5, which are respectively inclined 45?? Angle positioning and support. The size and size of two trapezoidal wooden templates 6 are consistent, and the long sides of two rectangular wooden templates 5 can be greater than or equal to the long side dimensions of trapezoidal wooden templates 6, but its short sides are consistent with the height dimensions of rectangular wooden templates 5. The structure of the inclination positioning support member 7 is as image 3, its main body is an isosceles right-angled triangle rib 7-1, along the hypotenuse of the isosceles right-angled triangle, an oblique backing wooden flute 7-2 is installed, and a horizontal backing wooden...

Embodiment 2

[0032] Example 2 The splicing method of the combined wooden formwork of the inclined column cap, the wooden formwork of the horizontal pallet and the wooden formwork of the cylinder

[0033] The splicing steps of the wooden formwork of the inclined column cap combination, the wooden formwork of the horizontal pallet and the wooden formwork of the column are as follows:

[0034] Such as Figure 10 , the horizontal pallet wooden formwork and column wooden formwork are installed on the scaffold 10 according to the conventional method, the horizontal pallet wooden formwork includes the horizontal pallet bottom formwork 8 and the horizontal pallet side formwork 15, and the center of the horizontal pallet bottom formwork 8 is reserved For the interface to be connected with the wooden formwork of the inclined column cap combination, a space position for installing the wooden formwork of the inclined column cap combination is reserved between the wooden formwork of the column body an...

Embodiment 3

[0037] Example 3 The construction method of the inclined column cap combined with the supporting plate and the column

[0038] The specific construction steps are as follows:

[0039] (1) Install column formwork and floor formwork

[0040] see Figure 10 and Figure 13 , set up the scaffolding 10, and install the column formwork 16, the outside of the column formwork 16 arranges the vertical wooden corrugated 17 and the pull bolt 11 (see Figure 13 ), and at the same time reserve the position for installing the column cap mold and the horizontal pallet mold above the column formwork 16, install the floor formwork corrugated 14 on the reserved position, and install the floor formwork corrugated 14 around the upper part of the reserved position, and install the floor formwork corrugated Install floor template 13 on 14. Floor template 13 reserves the central interface to be installed horizontal pallet wood formwork.

[0041] (2) Install horizontal pallet wood formwork

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com