Concrete water-based releasing agent produced by using drainage oil and preparation method thereof

A technology for waste oil and concrete is applied in the field of concrete water-based release agent and its preparation, which can solve the problems of high cost and low enthusiasm.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

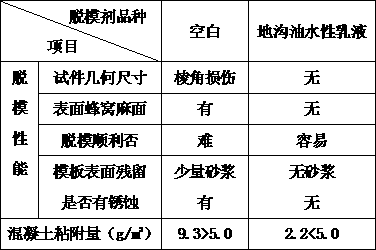

Image

Examples

Embodiment 1

[0023] Embodiment 1: add waste oil, emulsifier, auxiliary agent etc. in the reaction vessel after metering earlier, its batching is as follows:

[0024] Waste oil 15.5%, 32% NaOH 1%, triethanolamine 1.5%, engine oil 5.2%, sodium dodecylbenzenesulfonate 0.3%, sodium polyphosphate 0.5%, 2% methylcellulose 1.5%, water 74.5% .

[0025] The reaction temperature was 50°C, and the reaction time was 20 minutes.

Embodiment 2

[0026] Embodiment 2: add waste oil, emulsifier, auxiliary agent etc. in the reaction vessel after metering earlier, its batching is as follows:

[0027] Waste oil 9%, 32% NaOH 0.5%, triethanolamine 0.8%, stearic acid 1.5%, sodium dodecylbenzenesulfonate 0.1%, sodium polyphosphate 0.2%, 2% hydroxymethylcellulose 1%, Water 86.9%

[0028] The reaction temperature was 50°C, and the reaction time was 30 minutes.

Embodiment 3

[0029] Embodiment 3: add waste oil, emulsifier, auxiliary agent etc. in the reaction vessel after metering earlier, its batching is as follows:

[0030] Waste oil 16%, stearic acid 3%, 32% NaOH solution 1%, triethanolamine 1.5%, engine oil 5%, sodium dodecylbenzenesulfonate 0.1%, sodium polyphosphate 0.5%, methyl cellulose 2% Vegetable solution 1.5%, water 71.4%.

[0031] The reaction temperature was 60°C, and the reaction time was 20 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com