A precise and compact 3D printer powder supply mechanism and transmission method

A 3D printer, compact technology, applied in the field of printer powder supply mechanism, can solve the problems of complex structure and bulky powder supply mechanism, and achieve the effect of meeting transmission precision requirements, reducing layout space, and high linear motion accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

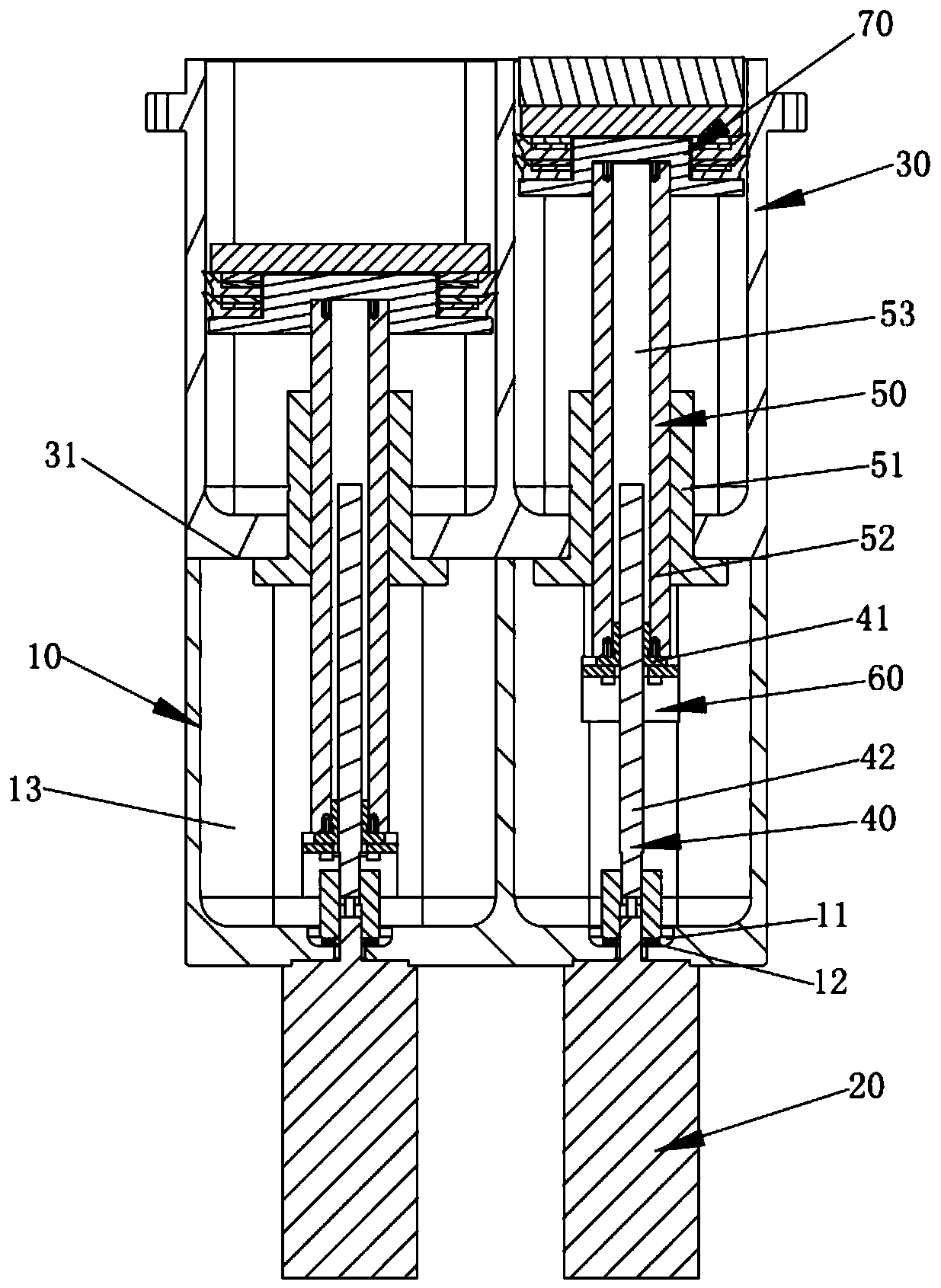

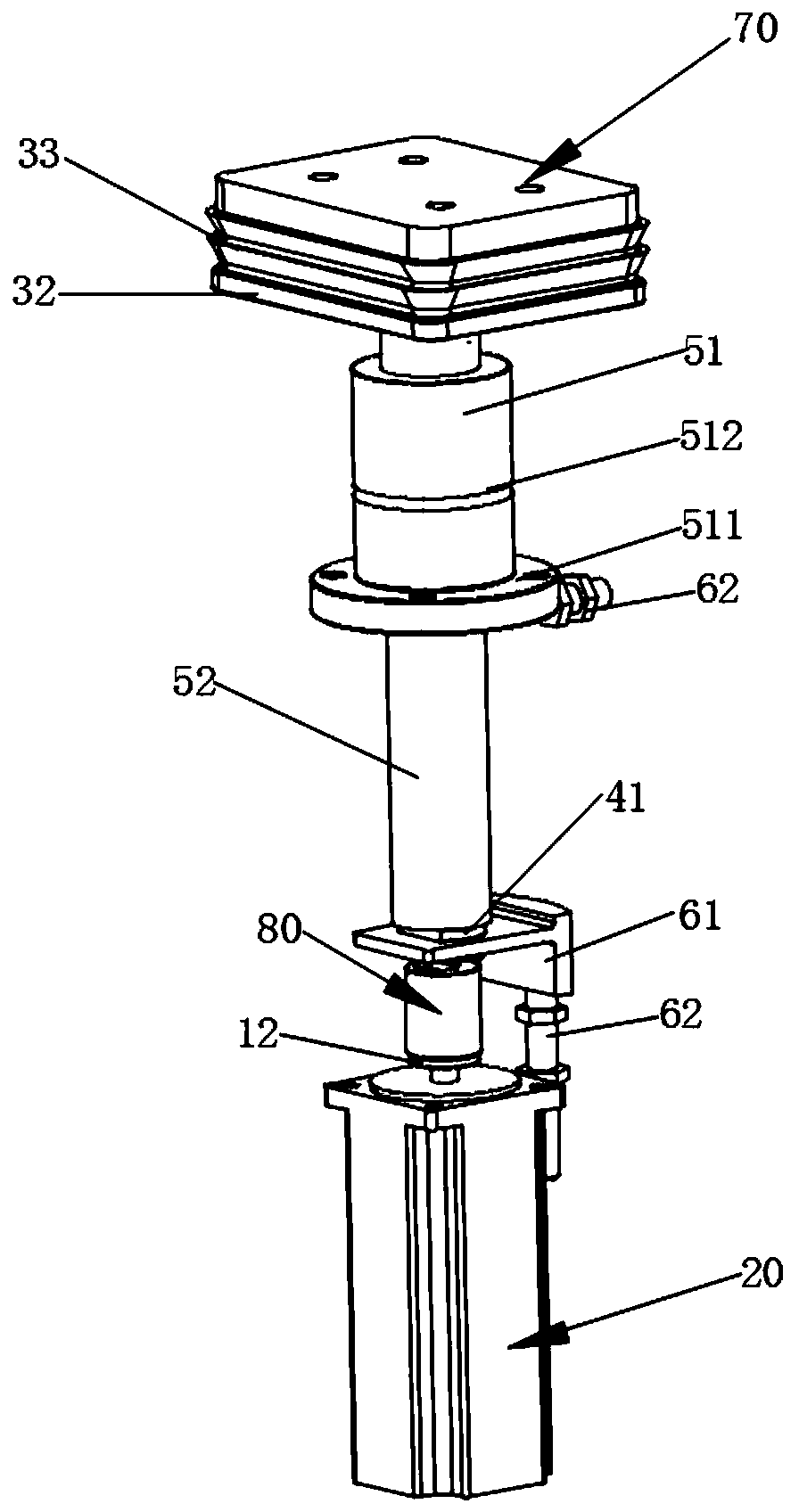

[0030] The main problem to be solved by the present invention is to change the existing transmission structure in which the screw rod and the guide rail cooperate, simplify the transmission structure and reduce the volume of the powder supply mechanism. Of course, on the basis of solving the problem, it is necessary to ensure the linear motion accuracy of the powder supply mechanism before it can be applied to 3D printer equipment. Among them, according to the characteristics of metal 3D printer molding, the distance of each feeding is required to be 0.02mm, and the repeat error is below 0.005mm. Therefore, the transmission parts connected to the workbench must have high linear motion distance accuracy and have controllable High performance and smooth movement.

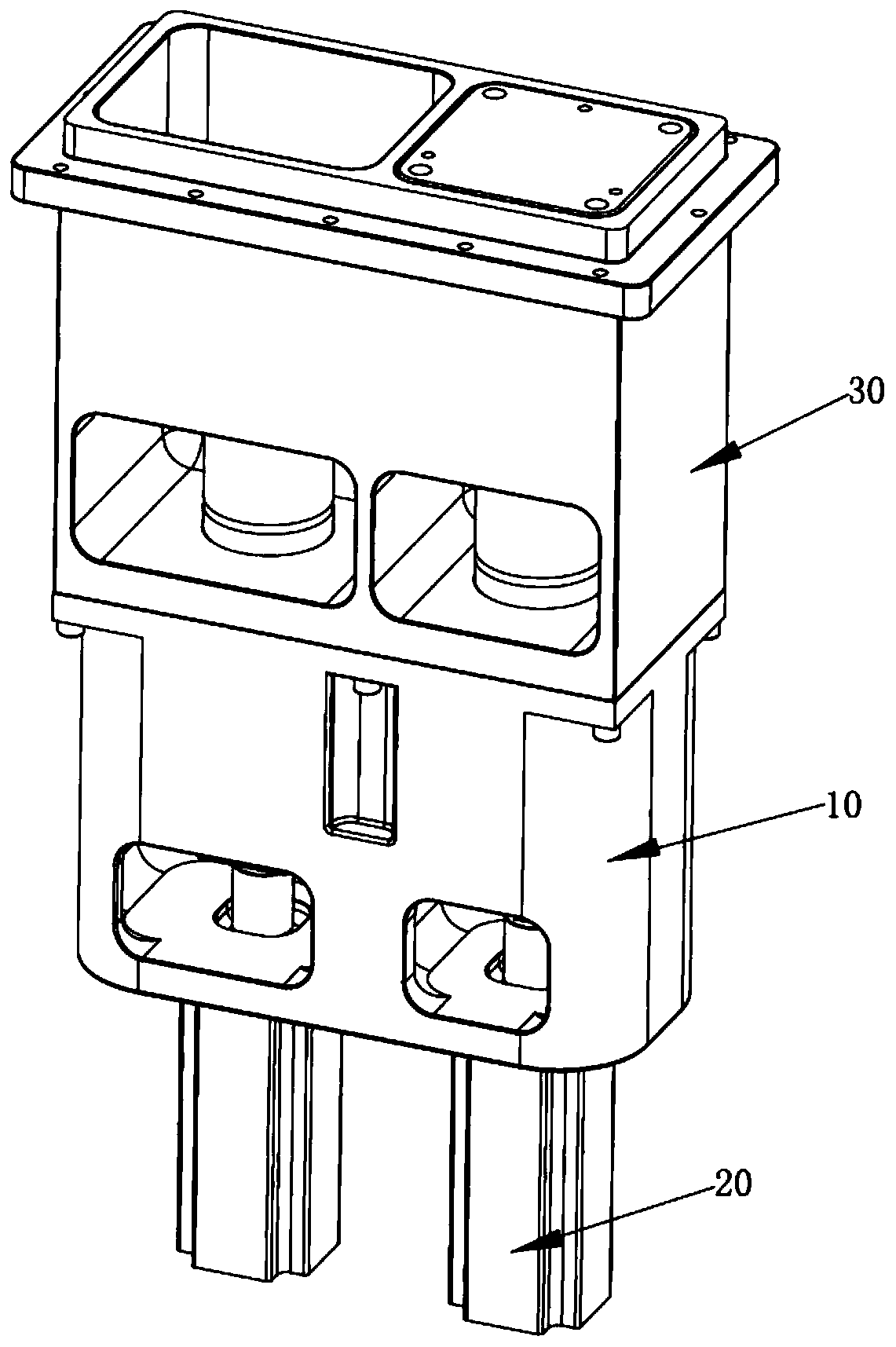

[0031] Please refer to figure 1 and figure 2 , a precision compact 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com