A Compensation Method for Laser Flatness Measurement Error

A compensation method and measurement error technology, applied in the direction of measurement devices, optical devices, instruments, etc., to achieve the effect of improving projection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In conjunction with the accompanying drawings, the present invention will be described in detail below.

[0044] 1. Main technical ideas

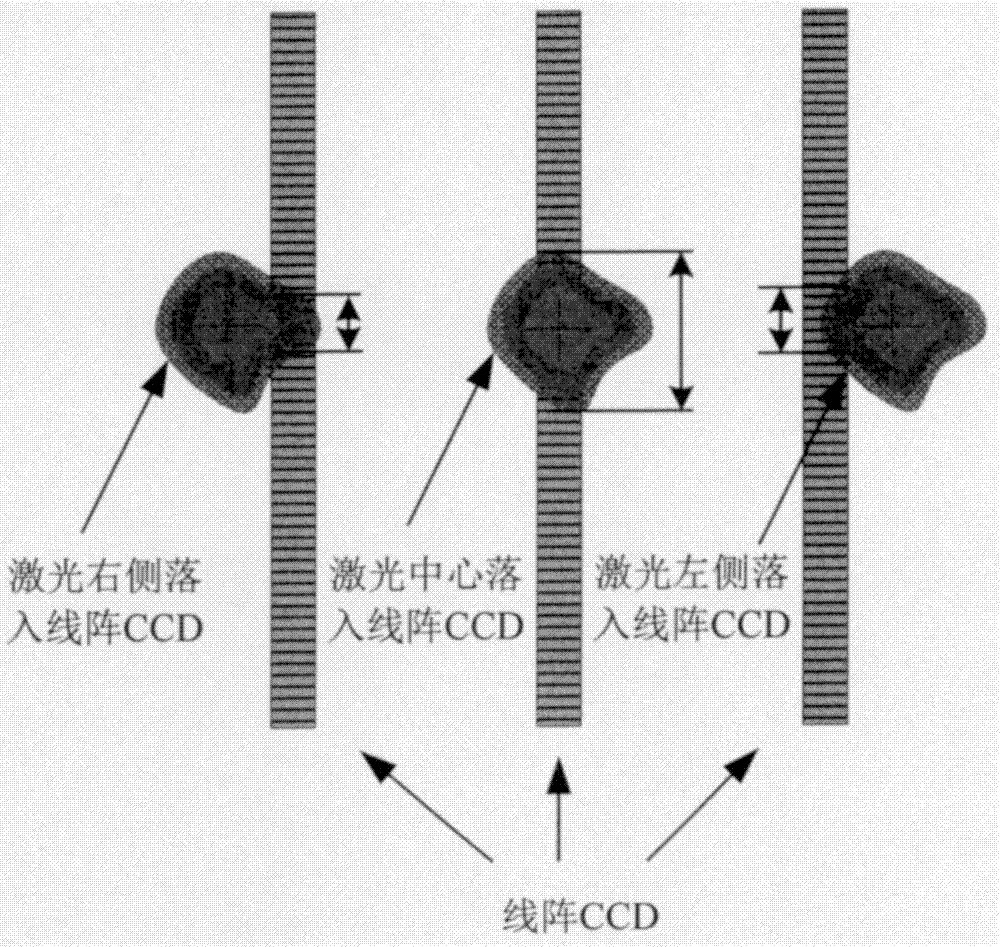

[0045] A laser flatness measurement error compensation method involved in the present invention, the main technical idea is that it is composed of three parts: sub-pixel image scattering compensation, reference inclination compensation, and spot variation centering compensation, which can effectively improve the laser flatness measurement system. measurement accuracy.

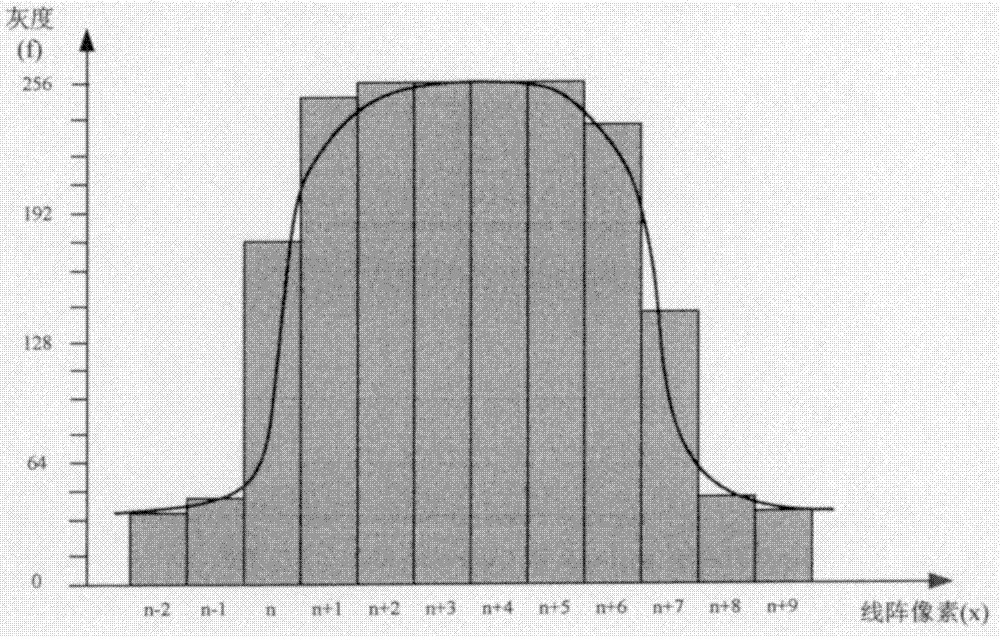

[0046] The sub-pixel image scattering compensation involved in the above technical route is to use the pixel edge recognition method to solve the scattering problem of the laser beam due to long-distance transmission, which can ensure the vertical accuracy of the plane measurement.

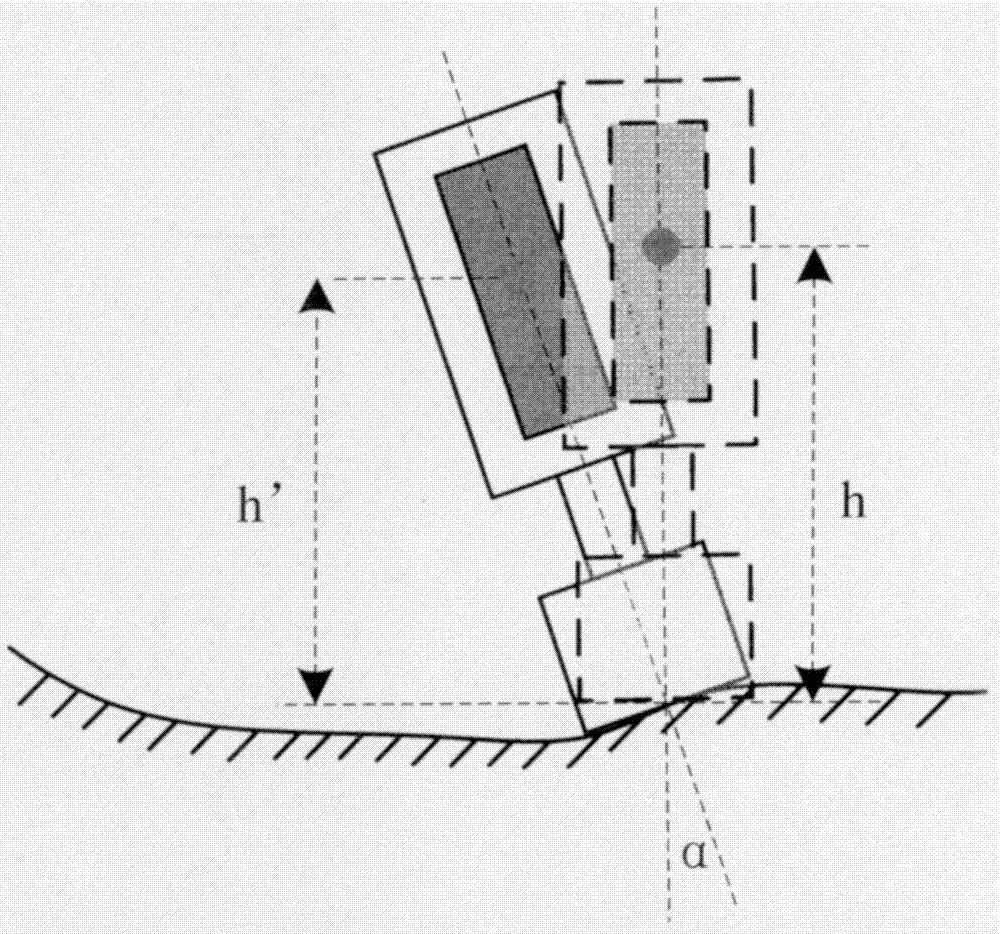

[0047]The reference inclination compensation involved in the above technical route uses the method of inclination transformation height to solve the problem of reference deviation in las...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com