Backlight module structure

A technology of backlight module and light guide plate, which is applied in the direction of optics, nonlinear optics, diffuser elements, etc., and can solve problems such as black tape falling off, light concentrated at the position of the lug, and unfavorable for mass production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

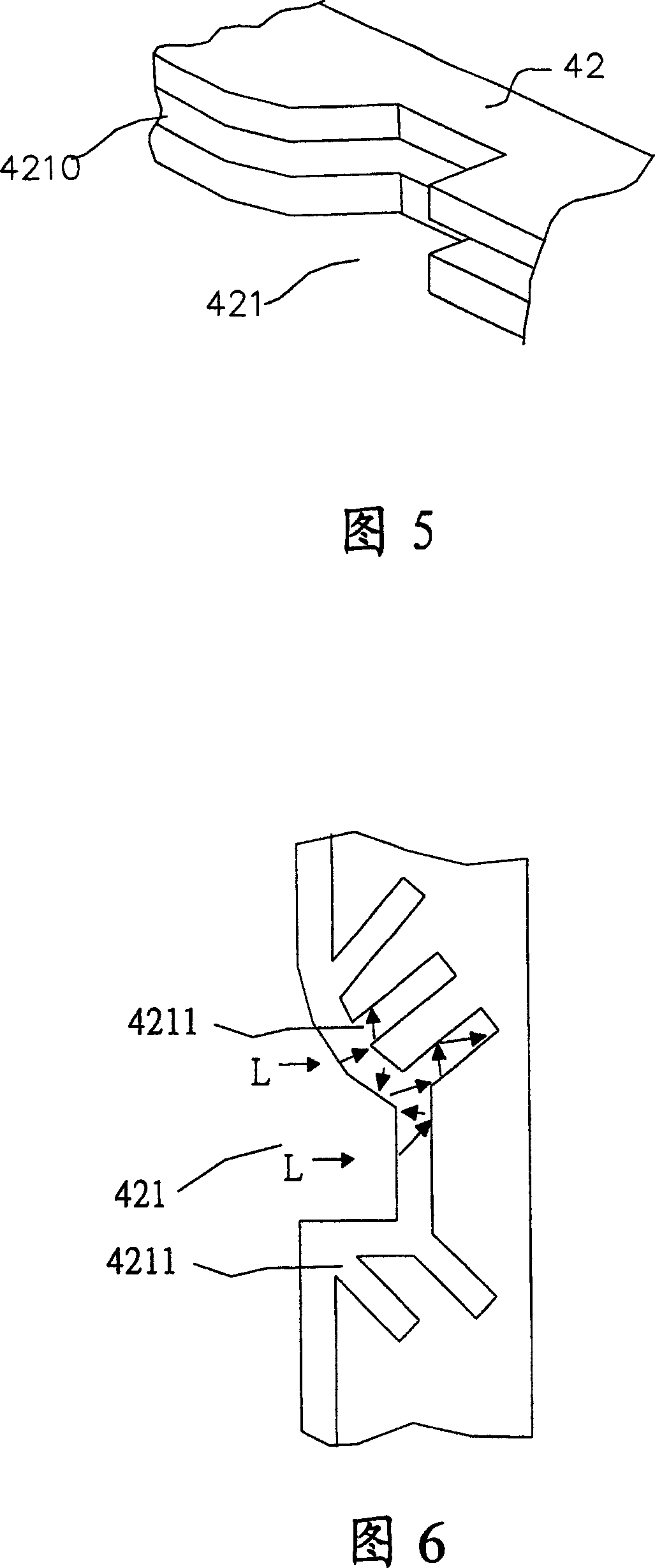

[0039] As shown in 5, the light guiding device is a groove 4210 arranged on the frame 42. The groove 4210 is opened along the frame 42. When the light scattered by the reflector reaches the groove 421 or any position of the frame 42, such as from In the L direction, the light will be diffused along the groove 4210 at this time, and will not be reflected back to the reflector, so that the situation where the light at the lug of the reflector is particularly bright can be avoided.

Embodiment 2

[0041] As shown in Figure 6, the light guiding device is a groove 4211 arranged near the groove 421 of the frame, mainly at the position where light is easily reflected back to the reflector, and is set inside the frame 42, forming a vertical or non-perpendicular angle with the frame Open; when the light scattered by the reflector reaches any position of the groove 421 or the frame 42, such as from the L direction, the light will be guided out along the groove 4211 and will not be reflected back Reflective plate.

Embodiment 3

[0043]As shown in Fig. 7, in this embodiment, the light guide device is not only arranged on the frame of the backlight module, but also arranged on the outer frame 43 used for fixing the frame 42, and the half part on the dotted line in Fig. Sectional view of the interior; half of the dotted line is a top view of the light guide device.

[0044] The light guide device is arranged in the groove 4212 near the groove 421 of the frame, mainly at the position where light is easily reflected back to the reflector, and is set inside the frame 42, runs through the frame 42, and the groove 4212 is perpendicular to the frame 42 Or non-perpendicular angle; when the light scattered by the reflector reaches any position of the groove 421 or the frame 42, such as from the L direction, the light will be guided out along the groove 4212 and always be exported At the same time, in order to prevent light from encountering the plane of the outer frame 43 and being reflected back along the origi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com