Single crystal polycrystalline nano-diamond composite thin film and preparation method

A technology of nano-diamond and composite film, which is applied in crystal growth, nanotechnology, nanotechnology, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

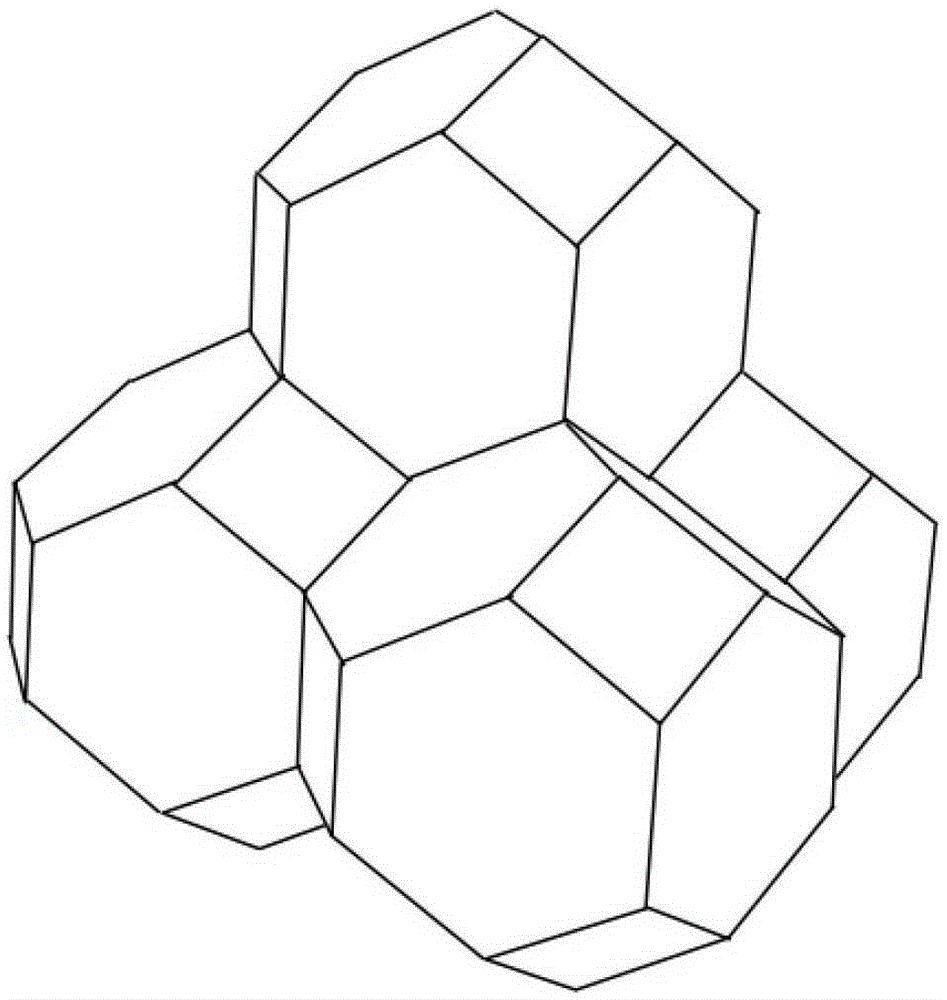

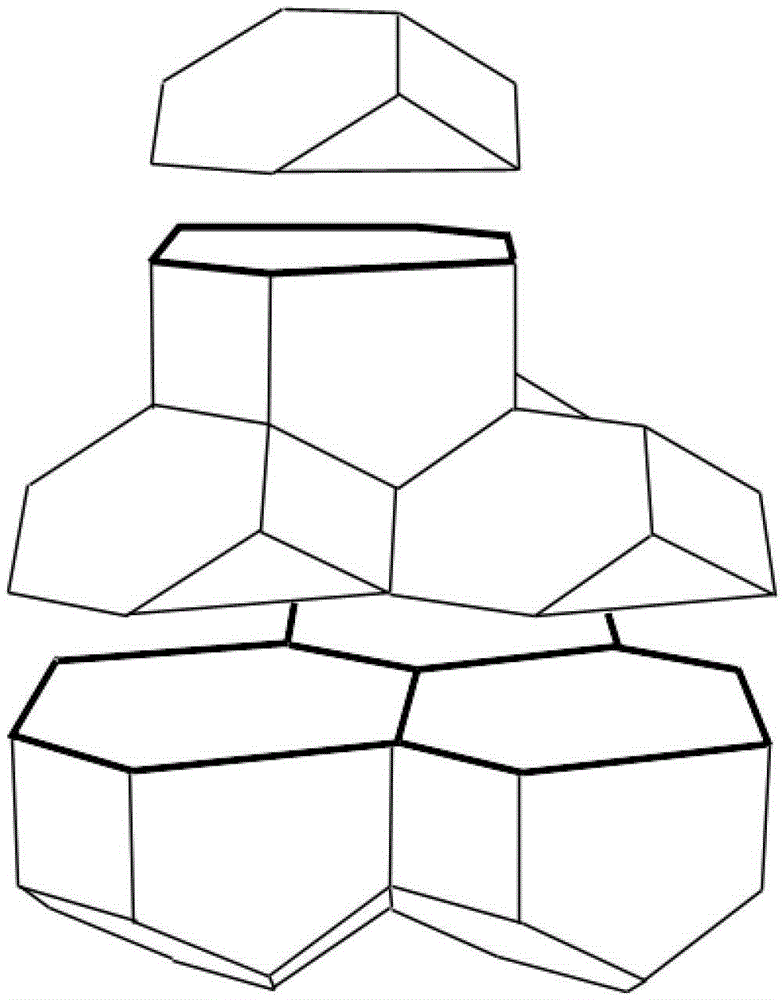

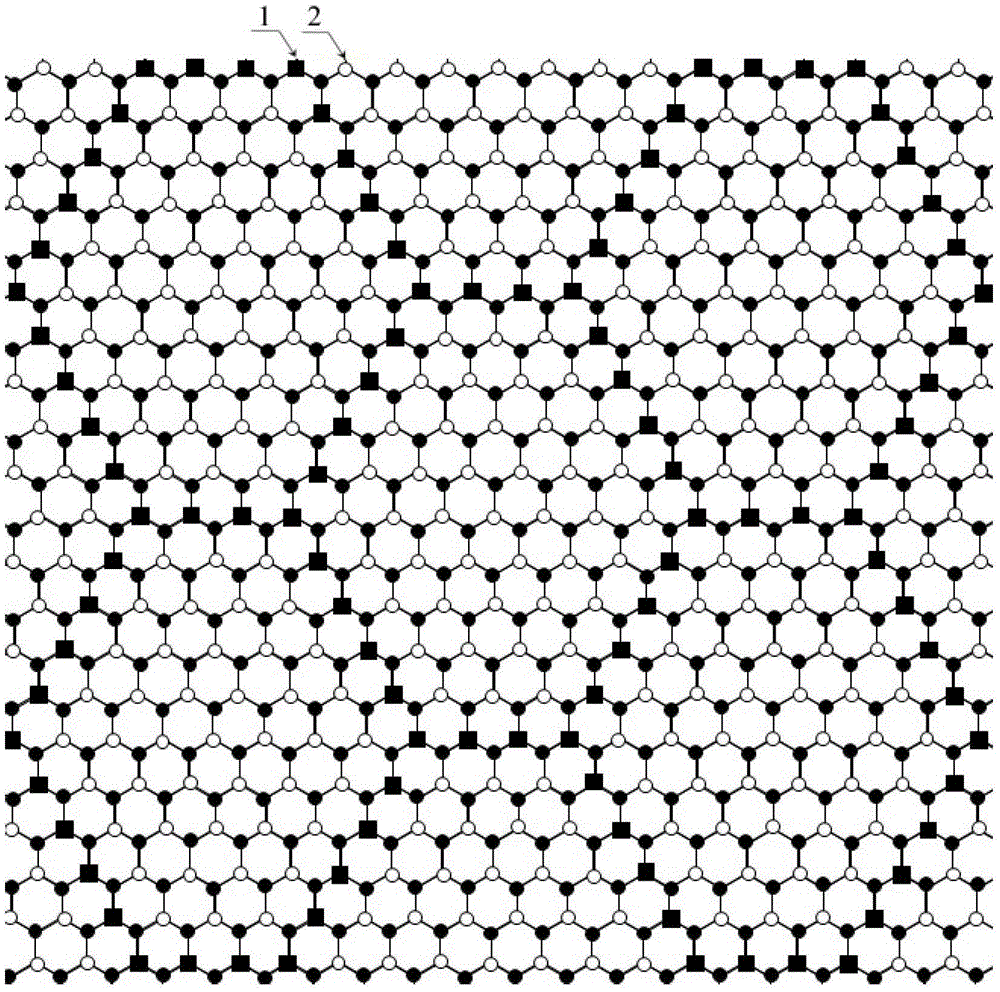

[0023] Embodiment 1: as figure 1 , figure 2 , image 3 , Figure 4 shown, where: figure 2 The thick border is the interface part, and the inside is the grain part; image 3 Particles 2 in are carbon (C) atoms represented by small circles, which form diamond grains, and the hollow and solid carbon (C) particles represent particles of different layers on the diamond (111) surface, respectively. image 3 Particle 1 in is silicon (Si) or germanium (Ge), boron (B) or aluminum (Al), phosphorus (P) or arsenic (As), or copper (Cu), gold ( Au), manganese (Mn) and other atoms, which combine with carbon (C) atoms in diamond to form an interface phase between crystal grains.

[0024] A single crystal polycrystalline nano-diamond composite film, the nano-diamond grain phase formed by carbon (C) particles 2 is separated by the interface phase formed by silicon (Si) particles 1, and the structure of the interface can be a replacement interface (such as image 3 ) or gap-type interfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com