Radial verticality detection platform

A verticality, single-wafer technology, applied in the direction of measuring devices, mechanical measuring devices, instruments, etc., can solve problems such as inability to guarantee the centering accuracy of crystal ingots, lack of detection methods, and affect the yield of square ingots, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

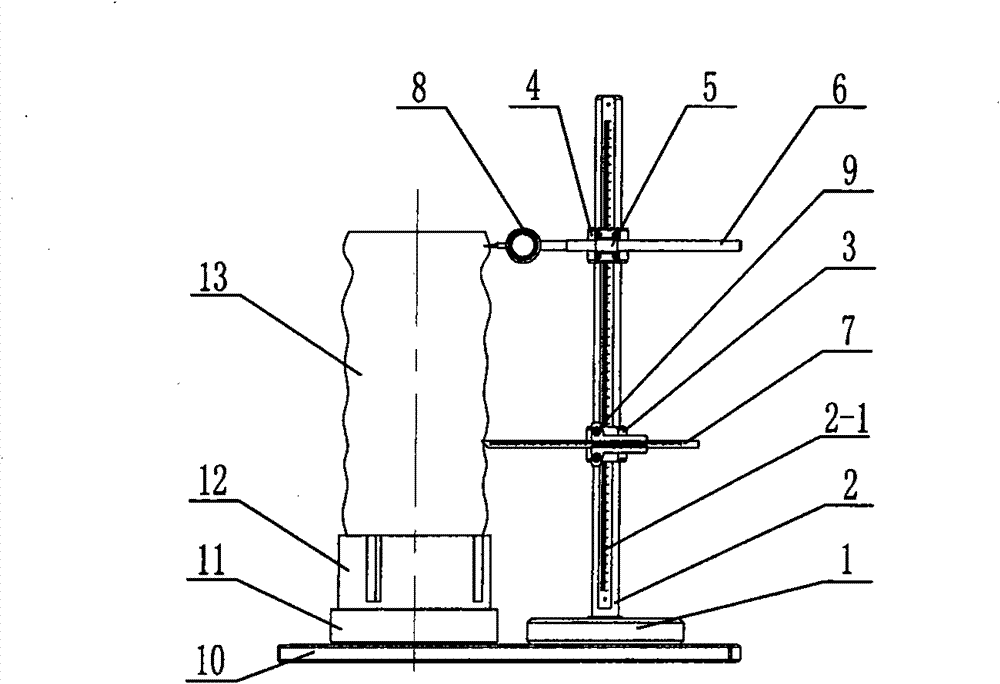

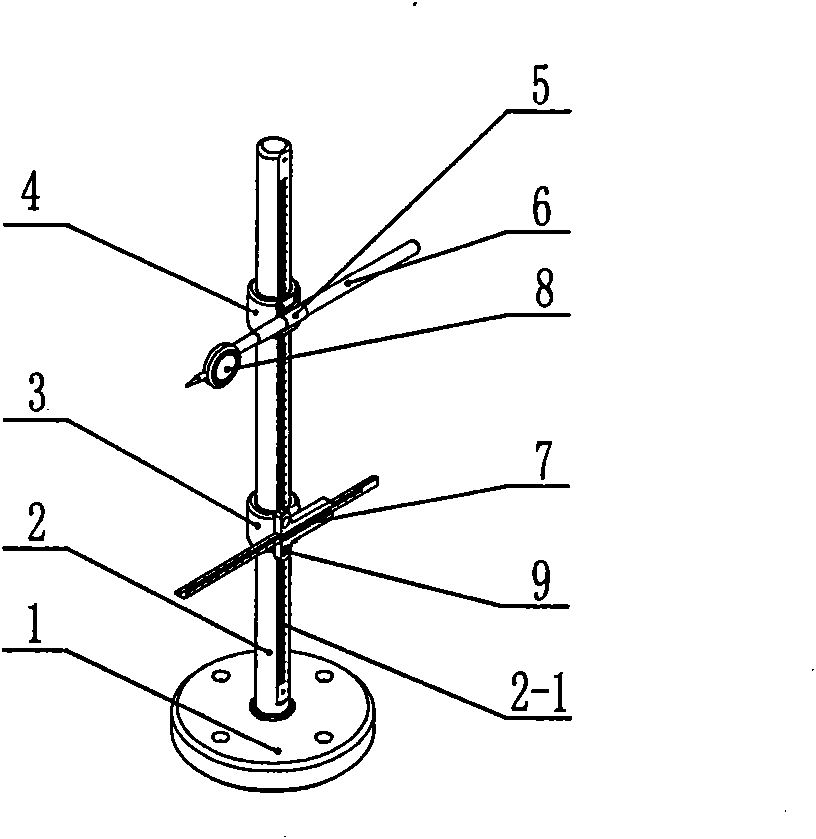

[0010] Such as figure 1 , 2 As shown, a single-wafer rod radial perpendicularity detection platform is composed of a base plate 10, a turntable 11, a column 2 with a scale 2-1, a depth measuring ruler 7 and an indexing table 8. The lower end of the column 2 has Base 1, the base 1 is fixed on the base plate 10 through its four positioning holes, the turntable 11 is rotatably supported on the base plate 10 through bearings, the depth measuring ruler 7 is movably installed on the column 2 through the moving sleeve 3, and the depth measurement The ruler 7 is fixed on the moving sleeve 3 through the inner hexagonal bolt 9, the moving sleeve 3 is set on the column 2, the indexing table 8 is movably installed on the column 2 through the table frame moving sleeve 4, and the table rod 6 of the indexing table 8 The pressure plate 5 is fixed on the tab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com