Cement mixing device for land photovoltaic power station construction

A technology of mixing device and photovoltaic power station, applied in cement mixing device, unloading device, clay preparation device, etc., can solve the problems of low mixing efficiency, reduction of construction speed of land photovoltaic power station, time-consuming and labor-intensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

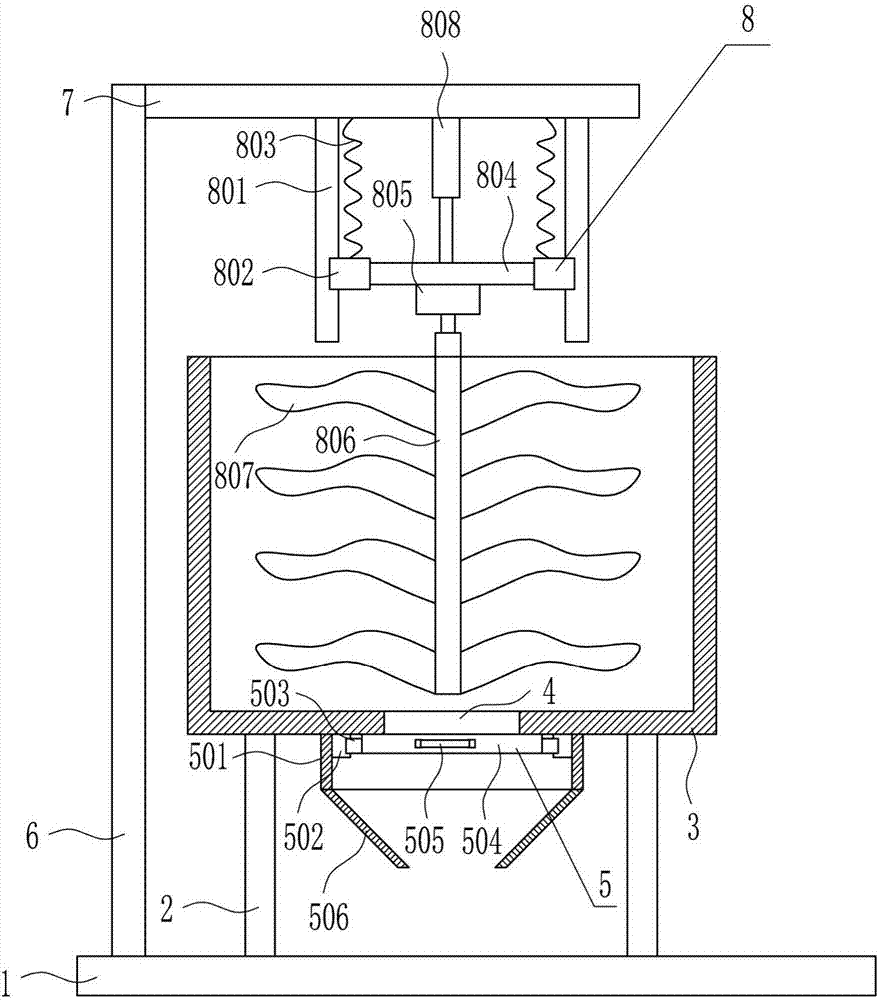

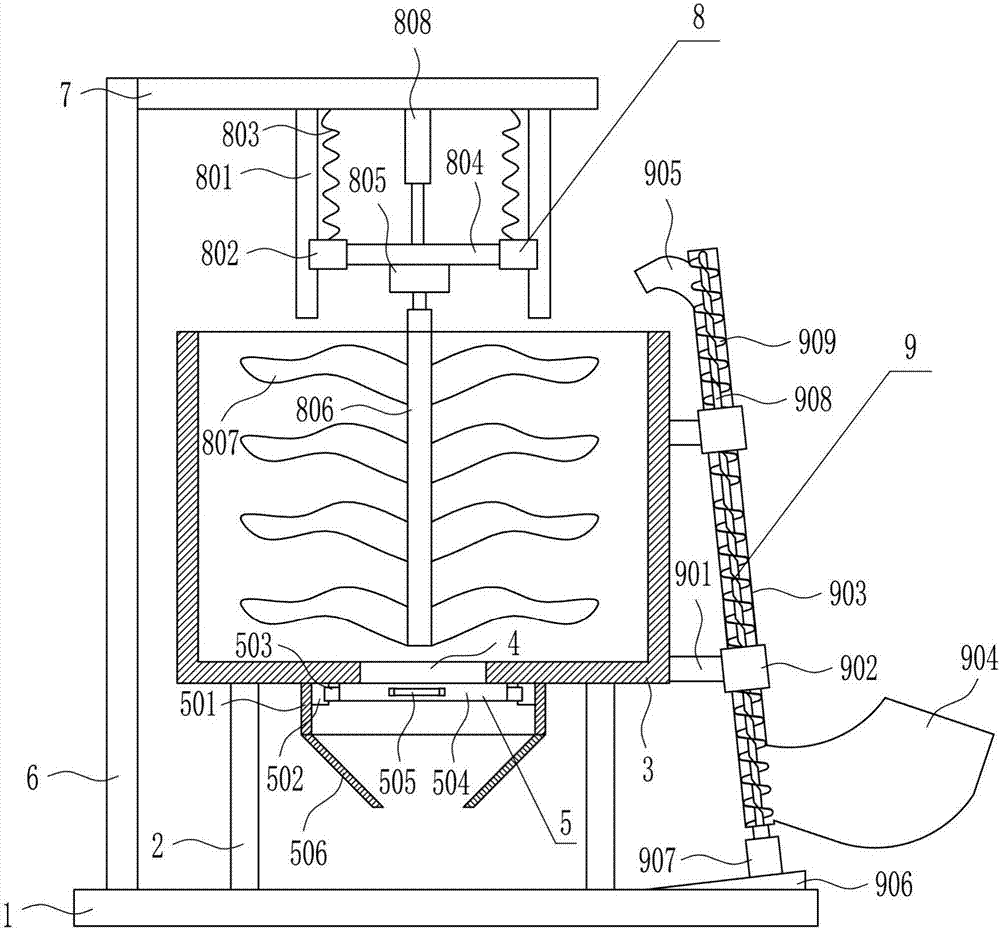

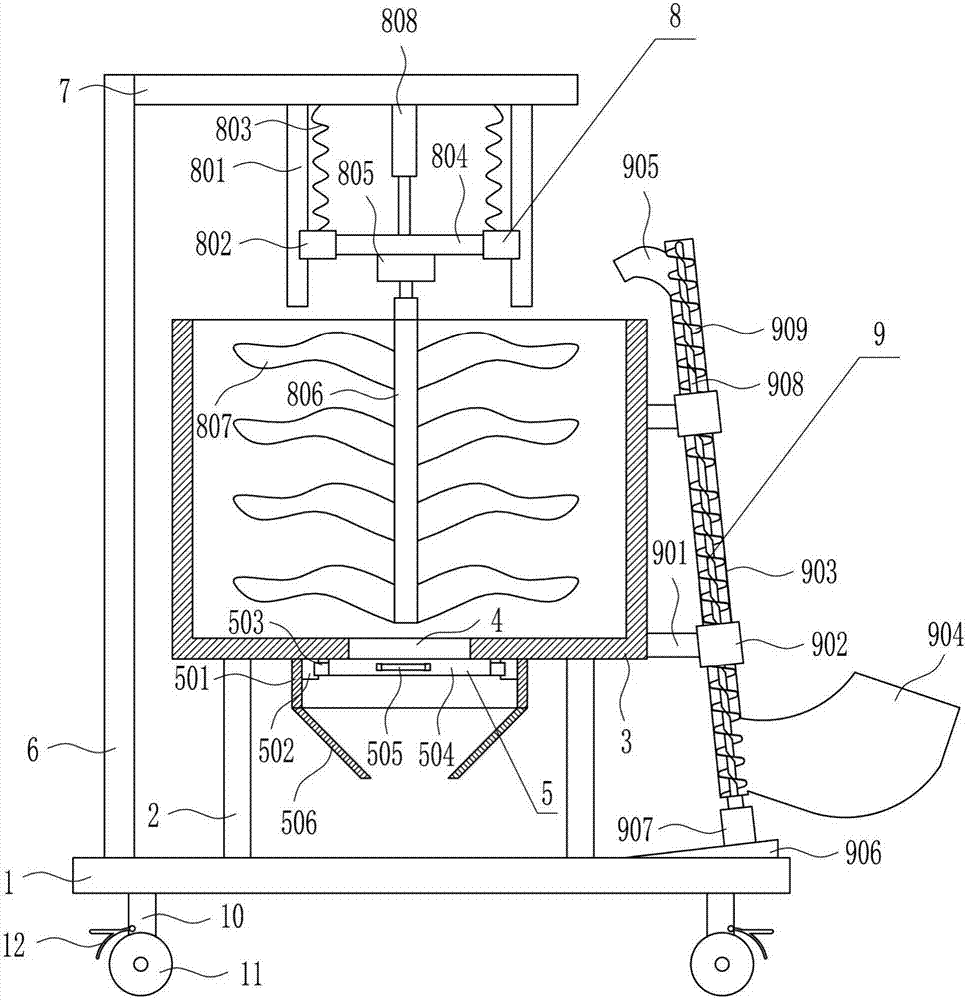

[0027] A cement mixing device for the construction of a land photovoltaic power station, such as Figure 1-3 As shown, it includes a bottom plate 1, a support plate 2, a mixing tank 3, a feeding device 5, a vertical plate 6, a top plate 7 and a stirring device 8. The top of the bottom plate 1 is provided with two support plates 2, and the two support plates 2 are about Symmetrical, the tops of the two support plates 2 are connected with a mixing tank 3 by bolts, the middle of the bottom of the mixing tank 3 is provided with a feeding port 4, and the bottom of the mixing tank 3 below the feeding port 4 is provided with a feeding device 5, and the stirring The top of the bottom plate 1 on the left side of the bucket 3 is connected with a vertical plate 6 by bolts, and the right side of the vertical plate 6 is connected with a top plate 7 by bolts. The bottom of the top plate 7 is provided with a stirring device 8, and the stirring parts of the stirring device 8 are located in the...

Embodiment 2

[0029] A cement mixing device for the construction of a land photovoltaic power station, such as Figure 1-3 As shown, it includes a bottom plate 1, a support plate 2, a mixing tank 3, a feeding device 5, a vertical plate 6, a top plate 7 and a stirring device 8. The top of the bottom plate 1 is provided with two support plates 2, and the two support plates 2 are about Symmetrical, the tops of the two support plates 2 are connected with a mixing tank 3 by bolts, the middle of the bottom of the mixing tank 3 is provided with a feeding port 4, and the bottom of the mixing tank 3 below the feeding port 4 is provided with a feeding device 5, and the stirring The top of the bottom plate 1 on the left side of the bucket 3 is connected with a vertical plate 6 by bolts, and the right side of the vertical plate 6 is connected with a top plate 7 by bolts. The bottom of the top plate 7 is provided with a stirring device 8, and the stirring parts of the stirring device 8 are located in the...

Embodiment 3

[0032] A cement mixing device for the construction of a land photovoltaic power station, such as Figure 1-3 As shown, it includes a bottom plate 1, a support plate 2, a mixing tank 3, a feeding device 5, a vertical plate 6, a top plate 7 and a stirring device 8. The top of the bottom plate 1 is provided with two support plates 2, and the two support plates 2 are about Symmetrical, the tops of the two support plates 2 are connected with a mixing tank 3 by bolts, the middle of the bottom of the mixing tank 3 is provided with a feeding port 4, and the bottom of the mixing tank 3 below the feeding port 4 is provided with a feeding device 5, and the stirring The top of the bottom plate 1 on the left side of the bucket 3 is connected with a vertical plate 6 by bolts, and the right side of the vertical plate 6 is connected with a top plate 7 by bolts. The bottom of the top plate 7 is provided with a stirring device 8, and the stirring parts of the stirring device 8 are located in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com