Bamboo-structure single-layer spherical latticed shell and assembling method

A bamboo structure, single-layer technology, applied in the field of bamboo structure single-layer spherical reticulated shell and assembly, can solve the problems of low connection reliability of bamboo nodes, reduce labor intensity and ground staff density, clear force transmission path, and connect Node Simple and Reliable Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

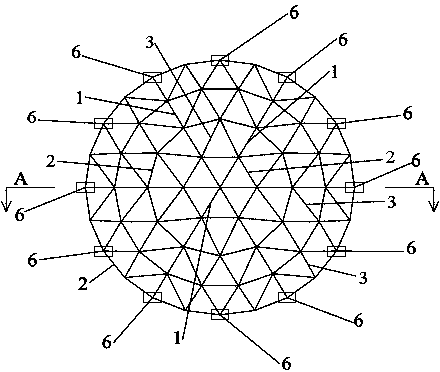

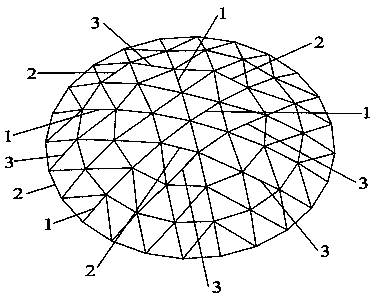

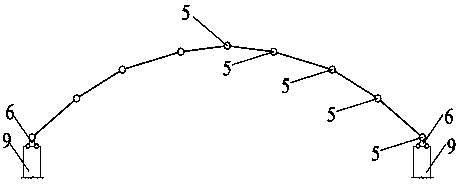

[0036] The method for assembling a single-layer spherical bamboo reticulated shell comprises the following steps:

[0037] 1) Component number

[0038] The bamboo reticulated shell in this example is a K6 type Kaiwitt single-layer spherical reticulated shell, and there are 5 turns from top to bottom, which are recorded as A, B, C, D, E in turn; there is a bamboo connector in the first turn , denoted as A1, there are 6 bamboo connectors in the second circle, which are respectively denoted as B1, B2, B3, B4, B5, B6; E1, E2...E24, the number of the hollow ball 5 in the bamboo connector is the same as that of the bamboo connector, the number of the fixed hinge support is the same as the number of the bamboo connector; the steel insert 4 is numbered according to the following rules, for example, the number of welding is A1 The 6 steel inserts 4 on the hollow ball 5 of the hollow ball 5 are numbered A1-a, A1-b, A1-c, A1-d, A1-e, A1-f respectively, and are welded on the hollow ball ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com