Pre-stressed anchor cable construction method

A kind of technology of prestressed anchor cable and construction method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

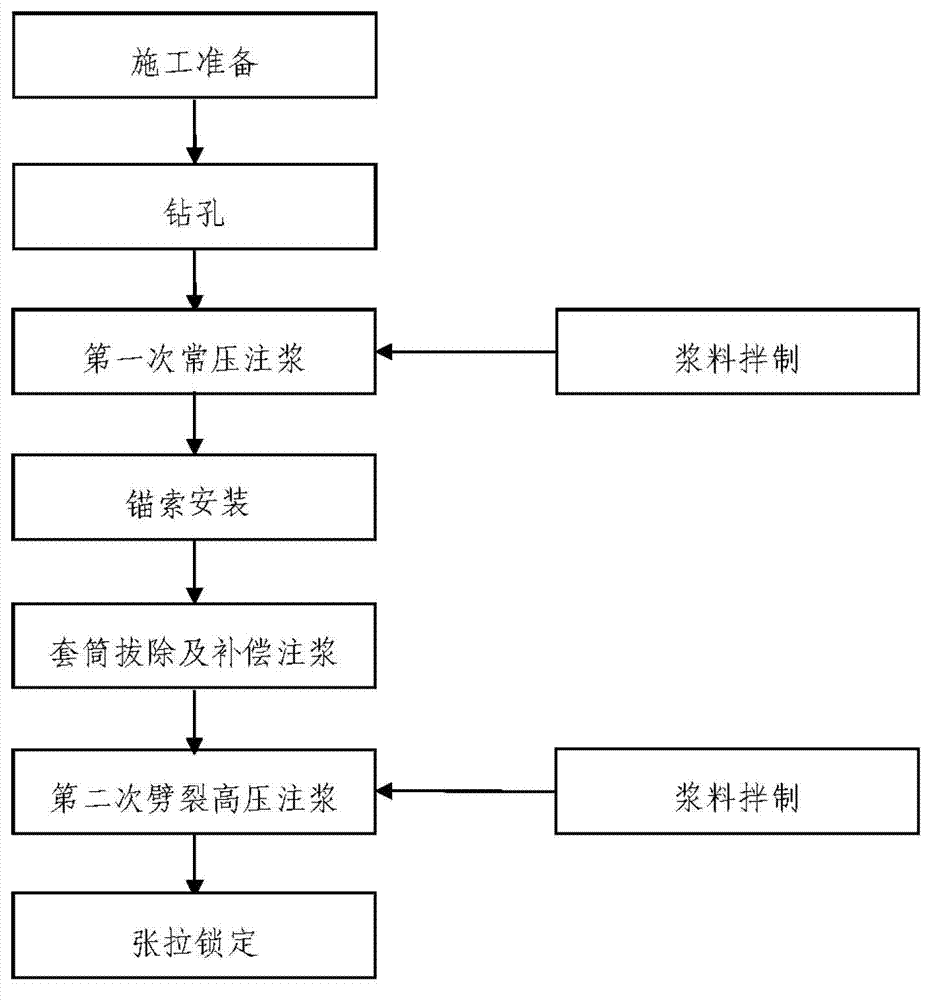

[0009] The prestressed anchor cable construction method of the present invention will be described below in conjunction with the accompanying drawings and specific examples.

[0010] In this example, the main geological conditions of the construction area are clay, silty clay, silt, silt fine sand, partly mixed with silt, rich groundwater, which belongs to water-rich and weak stratum. For this kind of stratum, it is difficult to ensure the quality of the hole and obtain the ideal pullout force by using the conventional anchor cable construction method.

[0011] On the basis of the traditional prestressed anchor cable construction method, the inventor of the present invention uses a sleeve to protect the anchor cable hole. During the hole forming process, the sleeve follows up. After the grouting and the anchor cable are lowered, the sleeve is pulled out , which can effectively prevent the anchor cable hole from collapsing and ensure the effective diameter and length of the anc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com