Equipment for producing novel non-woven cloth

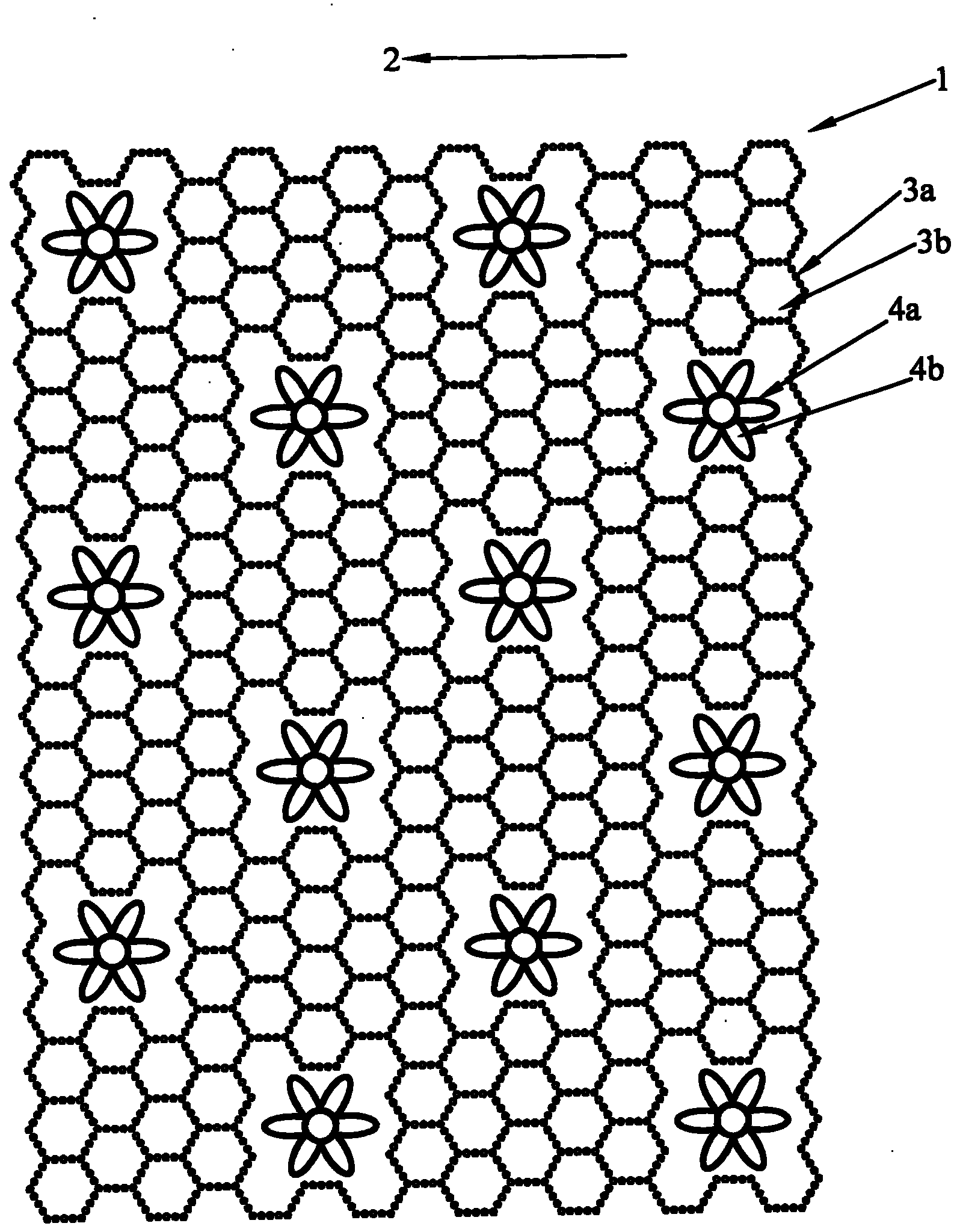

A technology for non-woven fabrics and production equipment, applied in the directions of non-woven fabrics, textiles and papermaking, fabric surface trimming, etc., can solve problems such as easy fluff, and achieve the effect of reducing the contact area and increasing the feeling of comfort.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Method Example 1: Hot air forming of nonwoven fabric, that is, the fiber web oriented in the running direction of the equipment is first shaped by a hot air blower at a temperature of 120 ° C and a wind pressure of 2000 Pa, and then the hot air formed nonwoven fabric is passed through a belt with engraved The hot rolling mill of the engraved roller, the temperature of the engraved roller is at 150 ℃, the total pressure of the roll web is processed under the condition of 10MPa to form the nonwoven fabric in the present invention, and the hardness of the lower engraved roller is 95HD.

Embodiment 2

[0039]Method Example 2: Hot air forming of nonwoven fabric, that is, the fiber web oriented in the running direction of the equipment is first shaped by a hot air blower at a temperature of 140°C and a wind pressure of 500Pa, and then the hot air formed nonwoven fabric is passed through a belt with engraved The hot rolling mill of the engraved roller, the temperature of the engraved roller is at 100°C, the total pressure of the roll web is processed under the condition of 2MPa to form the nonwoven fabric in the present invention, and the hardness of the lower engraved roller is 60HD.

Embodiment 3

[0040] Method Example 3: Hot air forming of nonwoven fabric, that is, the fiber web oriented in the running direction of the equipment is first shaped by a hot air blower at a temperature of 130 ° C and a wind pressure of 1000 Pa, and then the hot air formed nonwoven fabric is passed through a belt with engraved The hot rolling mill of the engraved roller, the temperature of the engraved roller is at 130 ℃, the total pressure of the roll web is processed under the condition of 5MPa to form the nonwoven fabric in the present invention, and the hardness of the lower engraved roller is 70HD.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com