Chassis air spring

An air spring and chassis technology, applied in gas shock absorbers and other directions, can solve the problems of short service life, inability to meet the lightweight, comfort, and poor vibration reduction effect of vehicle technology, so as to improve the vibration reduction effect and meet the requirements of light technology. Quantitative, lightweight effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

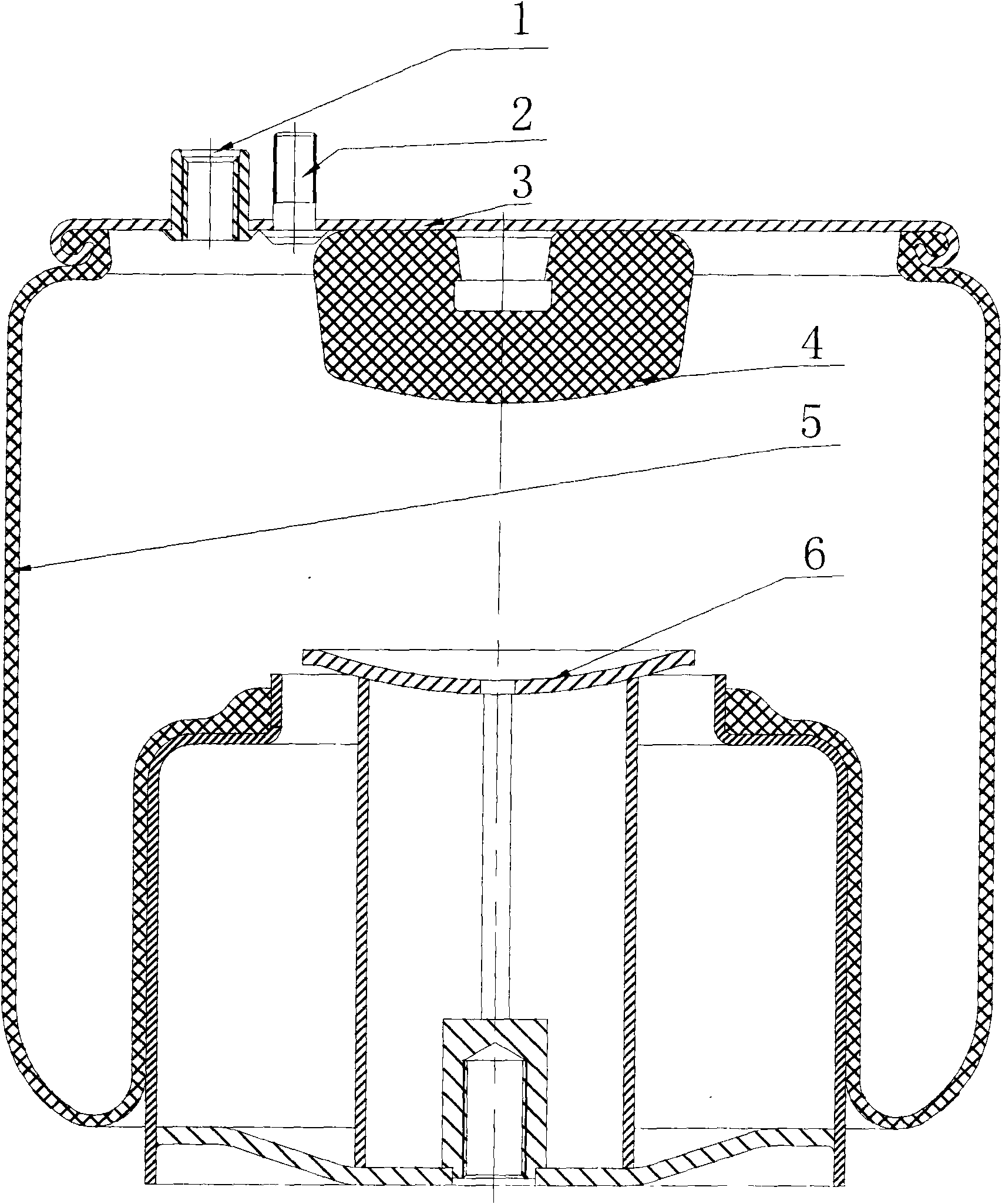

[0009] Such as figure 1 As shown, the bottom end of the capsule 5 is press-fitted with the side wall of the piston 6, the upper end of the capsule 5 is buckled and connected with the upper cover plate 3, and one end of the upper cover plate 3 is respectively provided with a trachea joint 1 and a positioning pin 2, and the trachea The joint 1 is hollow and communicates with the inside of the capsule 5. There is a protrusion in the middle of the bottom end of the upper cover plate 3. The emergency stopper 4 is connected with this protrusion. The entire piston 6 is made of metal material and is integrally constructed. The bottom end is also provided with a bolt hole. The gas pipe joint 1 is mainly used to connect the gas pipeline; the main function of the positioning pin 2 is to install and position, and the upper cover plate 3 is used to seal the gas and install; the main function of the emergency stop 4 is to carry out emergency stop in case of accident; the capsule 5 is an el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com