Audio speaker with back volume containing adsorptive material

a technology of audio speakers and back volumes, applied in the field of multi-cavity back volumes, can solve the problems of reducing the space available for a speaker back volume, the micro speakers tend to have limited performance in the bass range, so as to reduce the space available for speaker back volume and reduce the effect of low frequency acoustic performan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

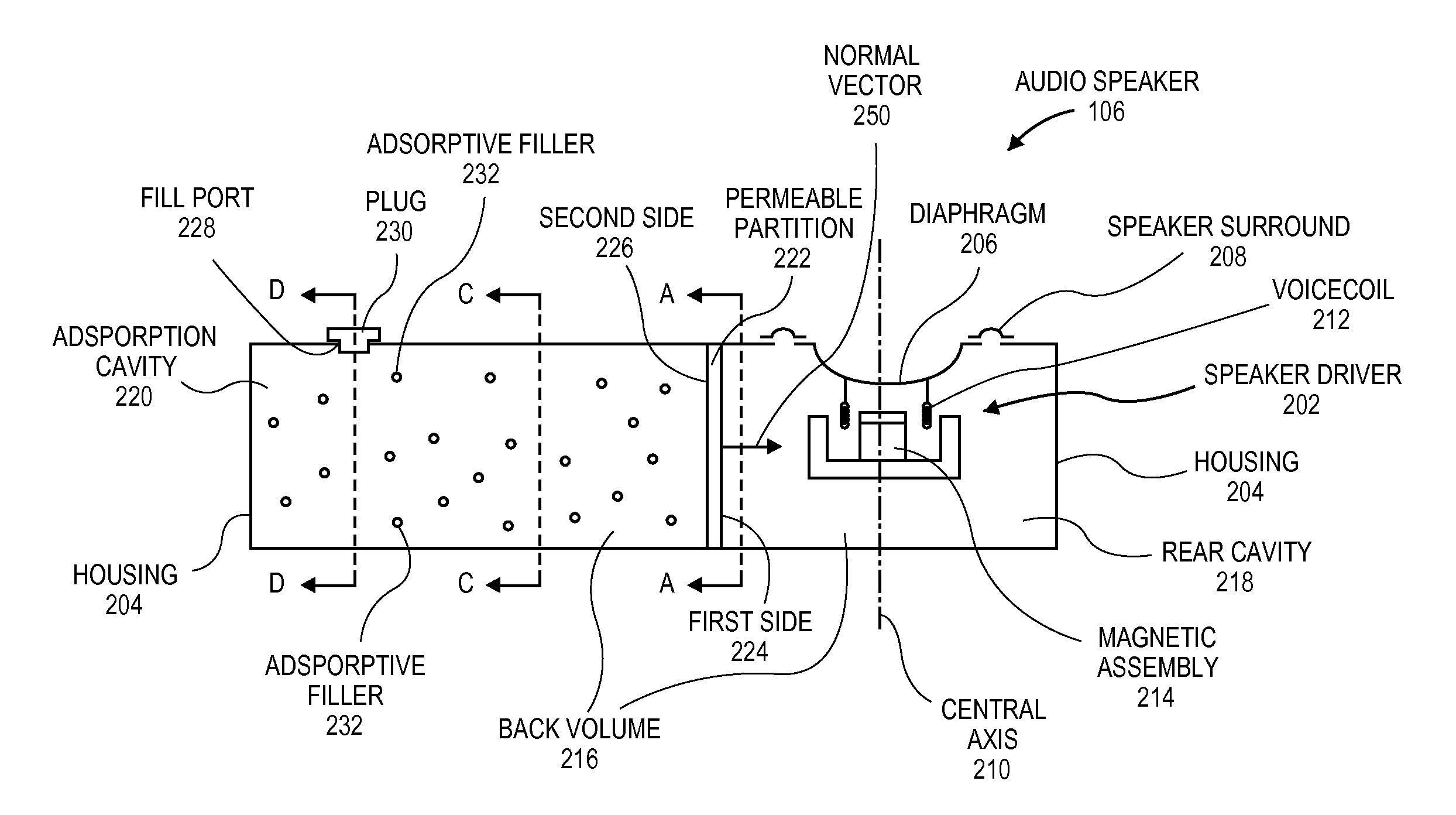

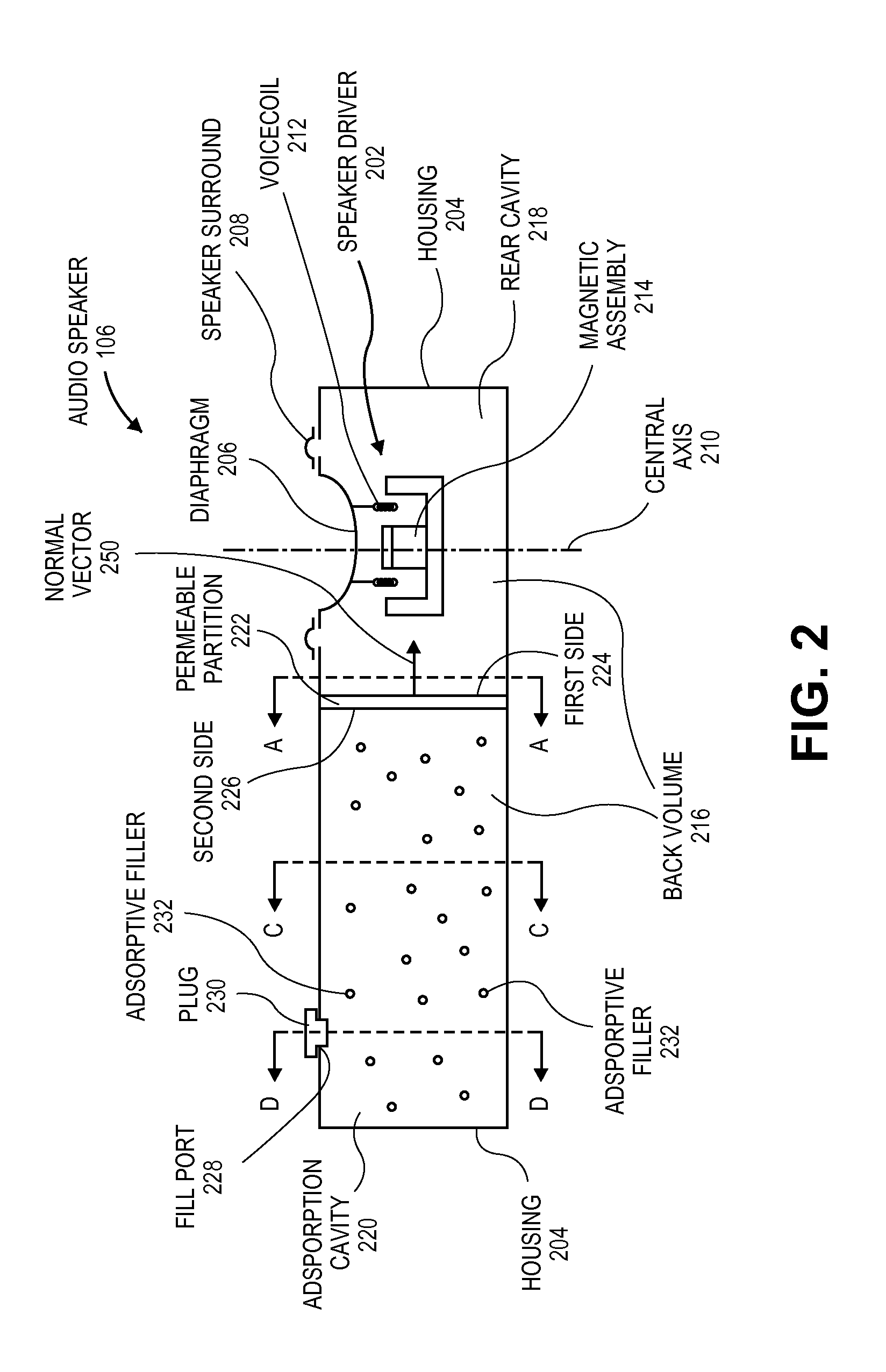

[0020]Embodiments describe an audio speaker having a speaker housing surrounding a back volume that is divided into several cavities (one of which contains an adsorbent material) by a permeable partition. However, while some embodiments are described with specific regard to integration within mobile electronics devices, such as handheld devices, the embodiments are not so limited and certain embodiments may also be applicable to other uses. For example, an audio speaker as described below may be incorporated into other devices and apparatuses, including desktop computers, laptop computers, or motor vehicles, to name only a few possible applications.

[0021]In various embodiments, description is made with reference to the figures. However, certain embodiments may be practiced without one or more of these specific details, or in combination with other known methods and configurations. In the following description, numerous specific details are set forth, such as specific configurations,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| lengths | aaaaa | aaaaa |

| lengths | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com