Ball spline supporting Stirling refrigerator

A technology of ball spline and ball spline shaft, which is applied in refrigerators, refrigeration and liquefaction, compressors, etc., can solve the problems of sealing wear restricting the life of the whole machine, high engineering cost, and many required parts, and achieve structural Simplicity, increased working life, and easy-to-connect effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

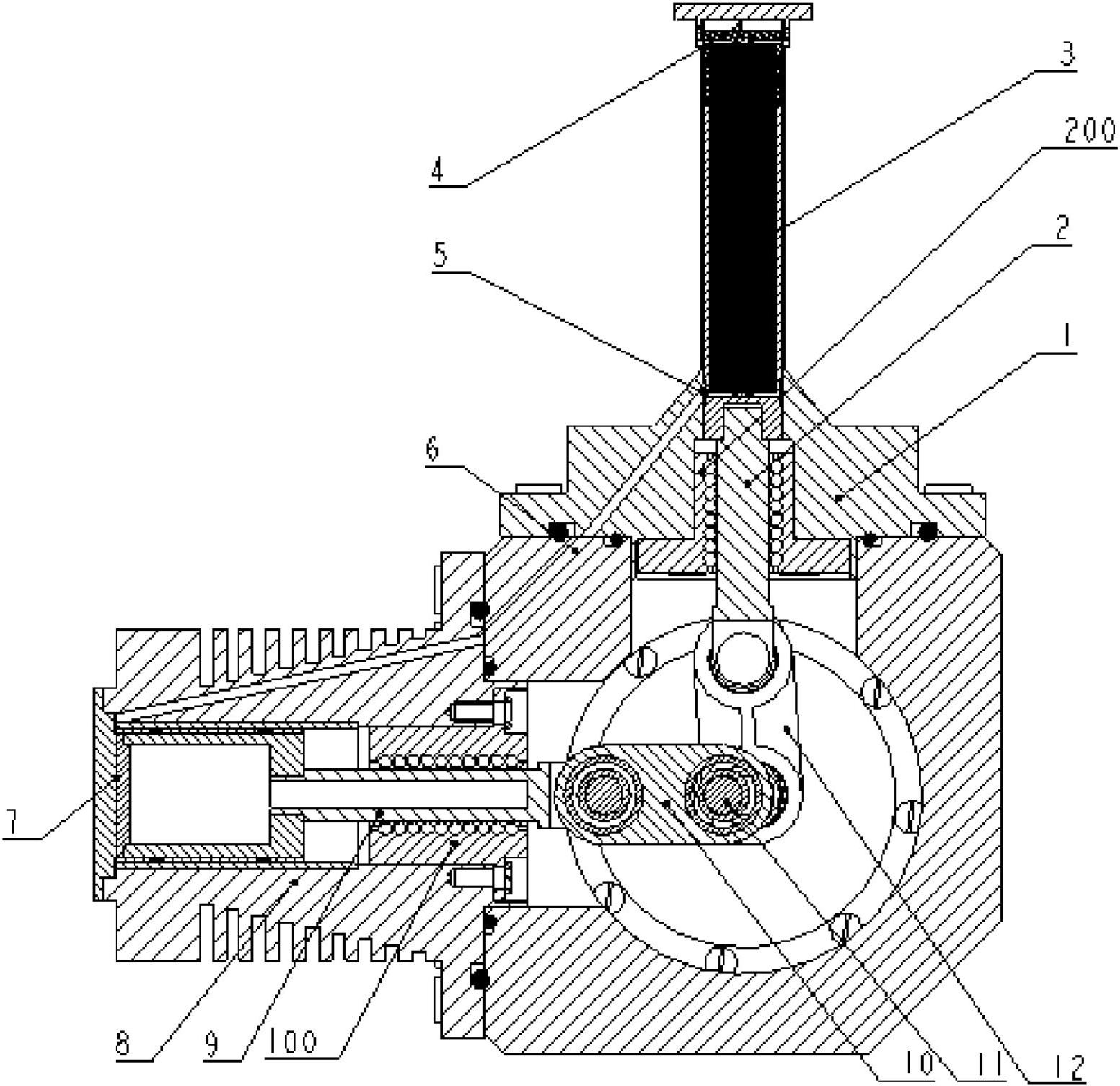

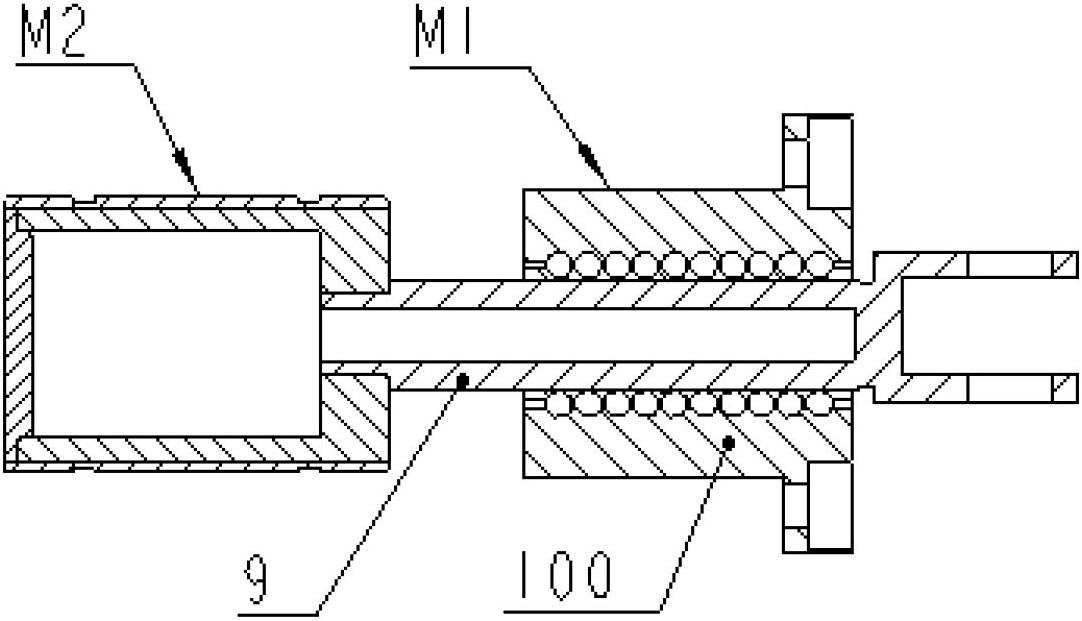

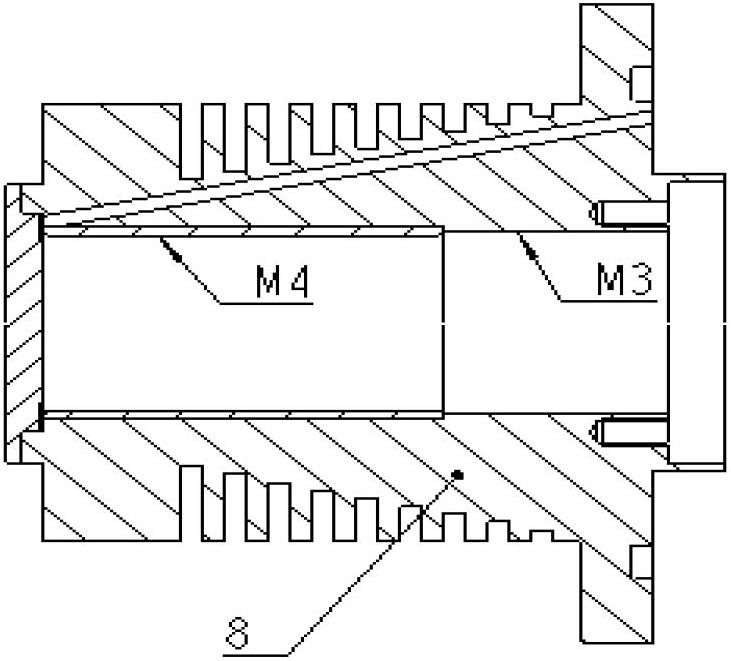

[0020] combine figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 , the ball spline supporting Stirling refrigerator of the present invention includes a compressor system, a cold head system, and a motor crankshaft drive system. The compressor system is composed of a cylinder 8 and a piston assembly, and the piston assembly is composed of a piston 9 and a piston ball spline 100. The cold head system is composed of a cold cylinder 1, an ejector 2, a heat regenerator 3 and an ejector ball spline 200. The heat regenerator 3 is located inside the ejector 2. The motor crankshaft drive system consists of a motor, a piston connecting rod 10, a crankshaft 11 and the ejector connecting rod 12, the cylinder 8, the cooling cylinder 1 and the motor are installed on the crankcase, the cylinder 8 and the cooling cylinder 1 are arranged at 90°, the piston 9 is connected with the piston connecting rod 10, and the ejector 2 is connected with the ejector The rod 12 is connected, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com