Novel ZR shaft assembly of horizontal multi-joint manipulator

A horizontal multi-joint, manipulator technology, applied to manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of high matching requirements for screw and spline drive, increased assembly and manufacturing costs, and high processing precision of parts, and achieve compact structure , simple manufacturing process and low precision requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

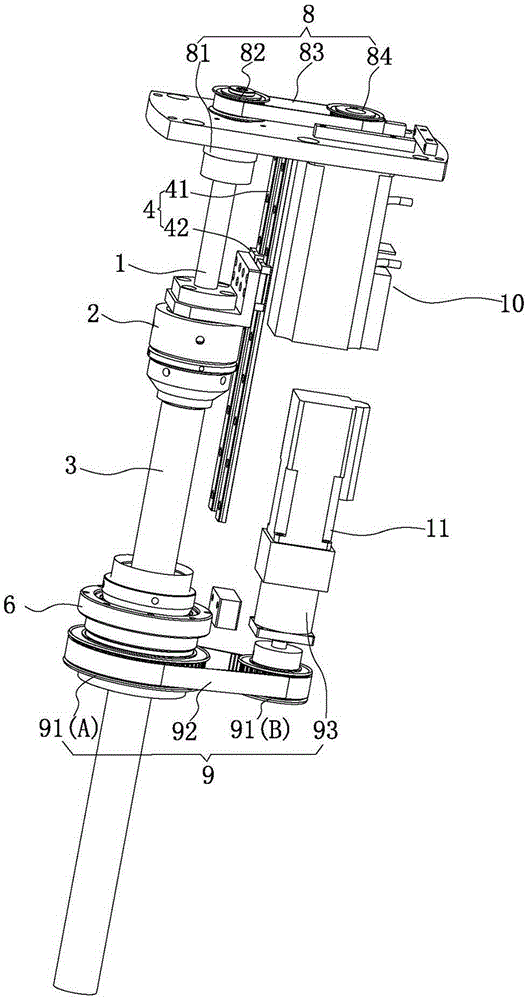

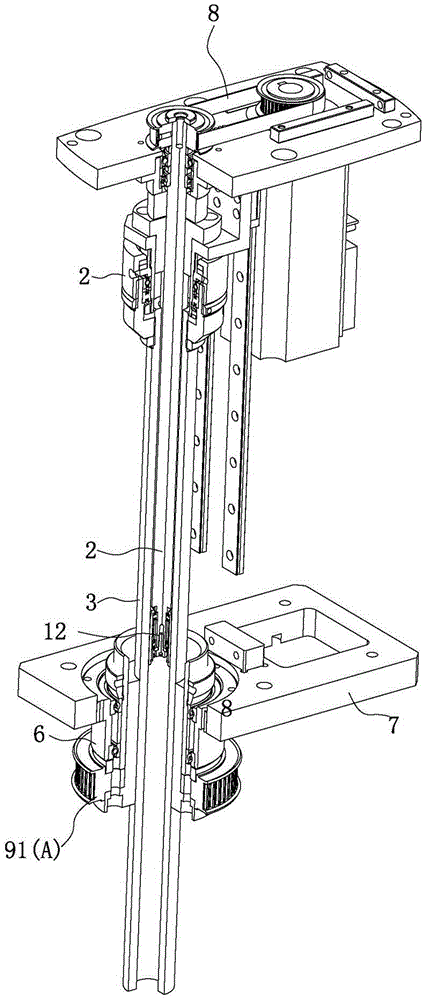

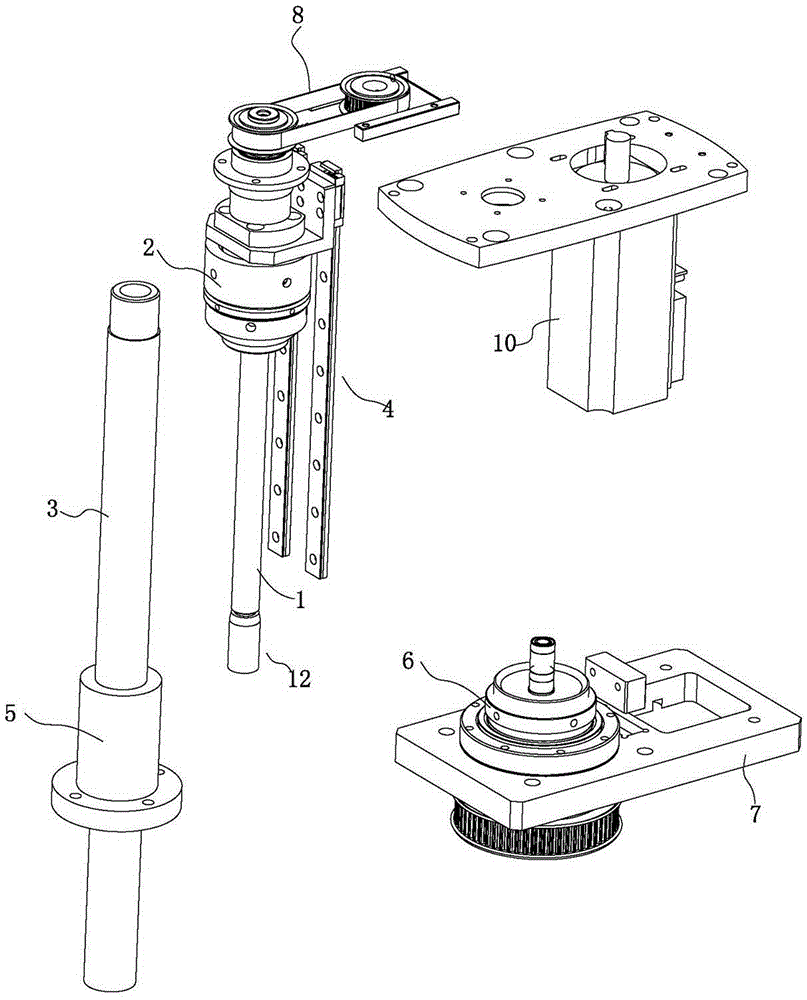

[0025] Figure 1-3 The specific embodiment of the present invention is illustrated, referring to the appended Figure 1-3 , an inventive ZR-axis assembly of a horizontal multi-joint manipulator, including a ball screw 1, the upper end of which is connected to the first driving device 10 through a first transmission assembly 8; There is a ball screw 1 nut, the lower end of the ball screw 1 nut is connected to the ball spline shaft 3, and the ball spline shaft 3 is provided with a hollow inner hole for the ball screw 1 to be inserted into (not shown in the figure). ), the ball screw 1 can be moved into and out of the inner hole, and the ball screw 1 and the ball spline shaft 3 are coaxially arranged. In this embodiment, the upper end of the ball s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com