Robotic planetary polishing unit for polishing of large-diameter aspheric surfaces

A polishing device and aspherical surface technology, which is applied in the direction of grinding/polishing equipment, optical surface grinders, grinding machines, etc., can solve the problems of insufficient pressure control accuracy, limited adjustment range, and low processing efficiency, so as to improve balance performance and increase The effect of controlling precision and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

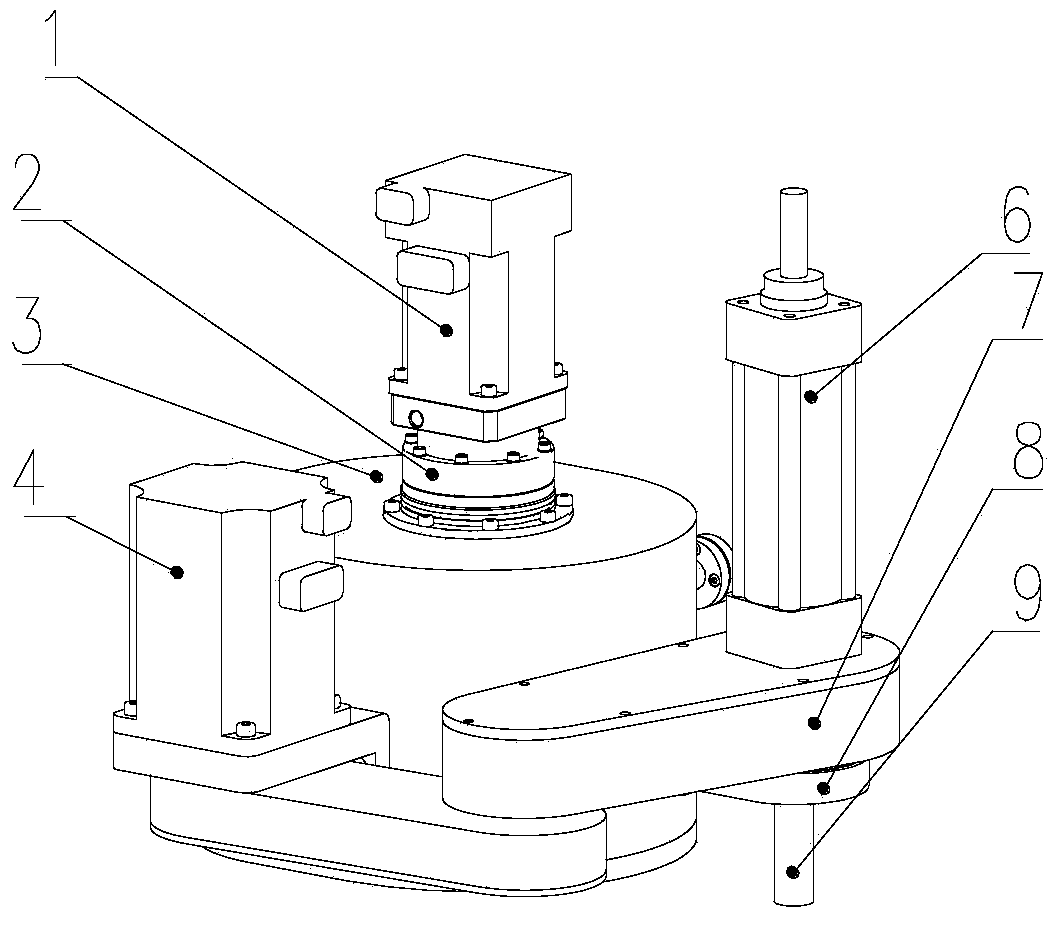

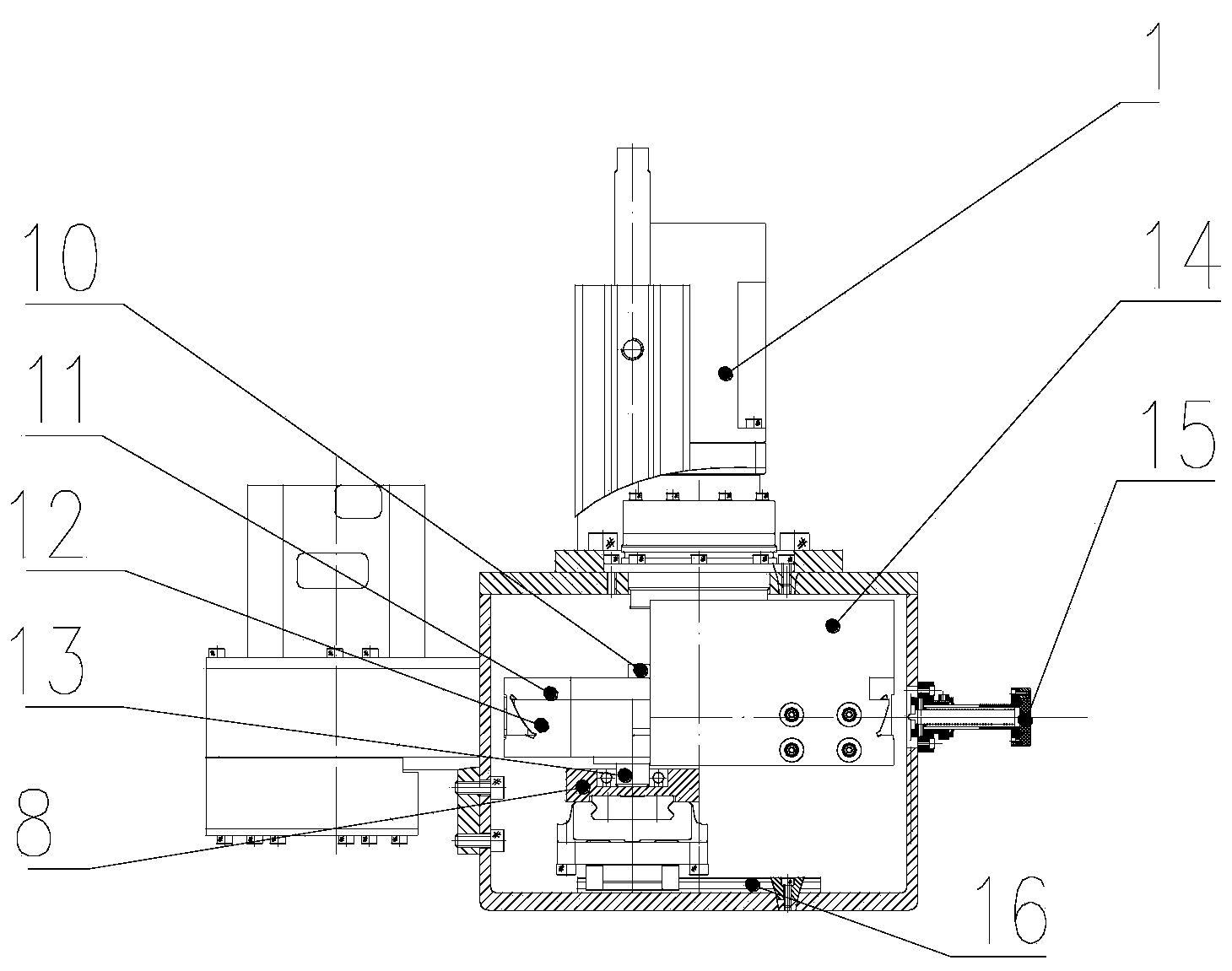

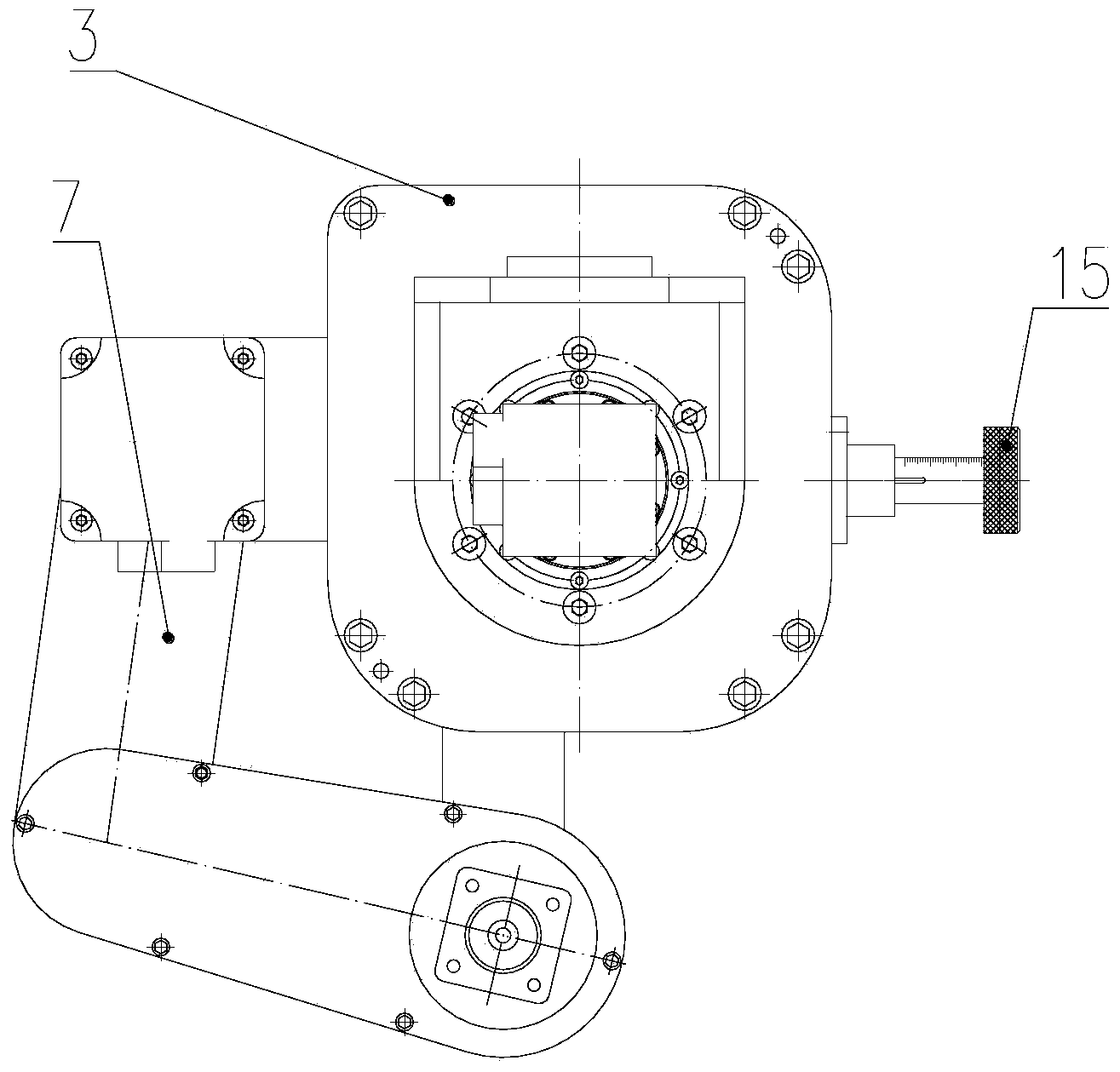

[0021] see Figure 1 to Figure 7 , a large-diameter aspheric robot planetary polishing device, comprising a revolution transmission mechanism, an autorotation transmission mechanism, a polishing shaft assembly, and a balance weight eccentric adjustment device.

[0022] The polishing shaft assembly includes a low-friction cylinder 6 and a female rotary ball spline, the female rotary ball spline is provided with a spline shaft 9 and a spline nut 17 slidably connected thereto, the piston of the low-friction cylinder 6 The rod is connected to the spline shaft 9 through a transition joint 20 and a rotary joint 21, the spline shaft 9 is used as a polishing shaft, and the transition joint 20 is affixed to the lower end of the piston rod of the low-f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com