Tyre building machine combined roller and method thereof

A technology of tire building machine and rolling device, applied in the field of rubber machinery, to reduce debugging time, improve bonding quality, and reduce wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

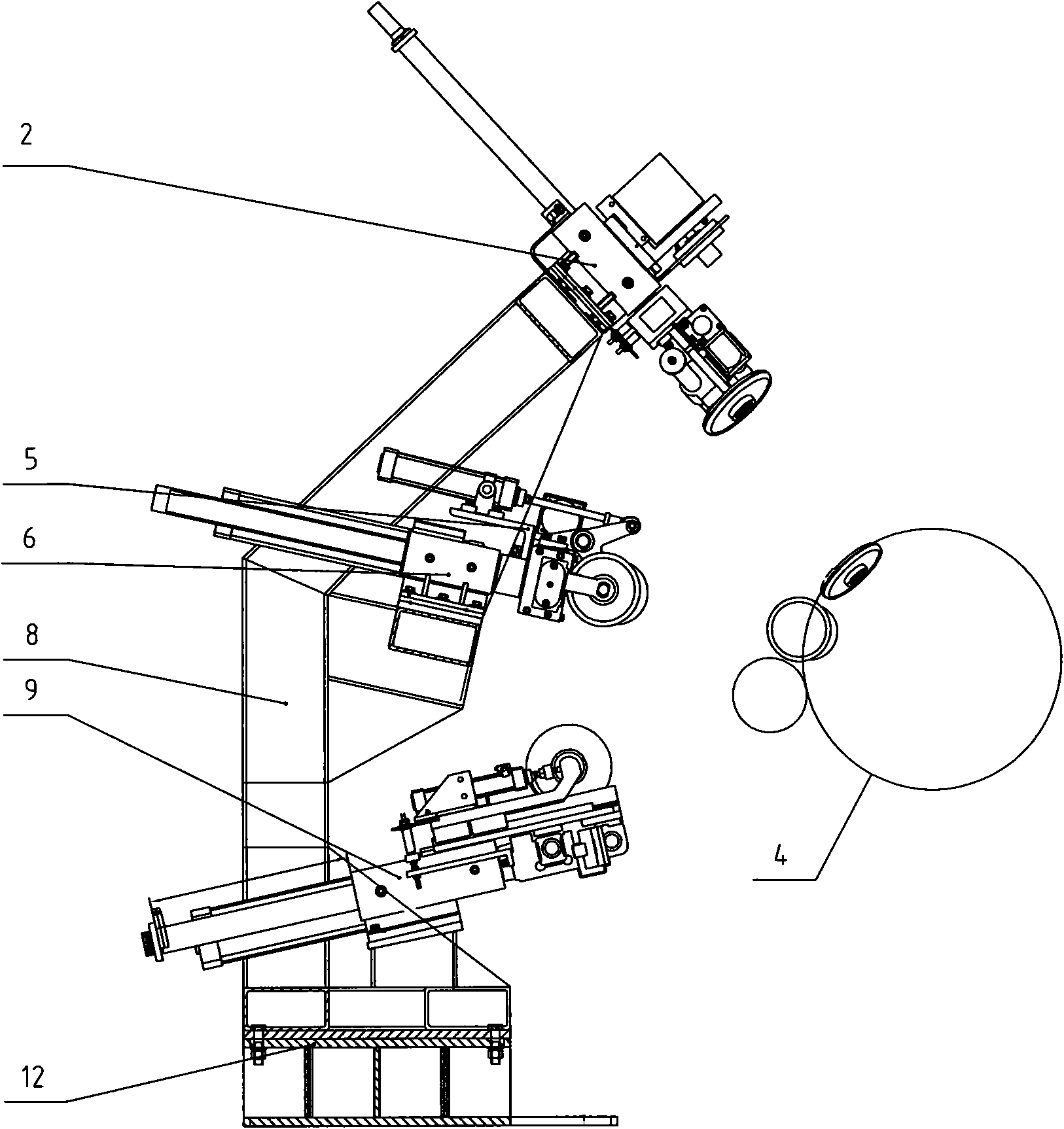

[0050] Example 1, such as Figure 1 to Figure 5 As shown, the combined rolling device of the tire building machine includes a frame 8 installed on a base 12, and a first roller device 5, a second roller device 6, a third roller device 2, and a fourth roller device 9 respectively pass through The respective brackets are connected to the frame 8. among them,

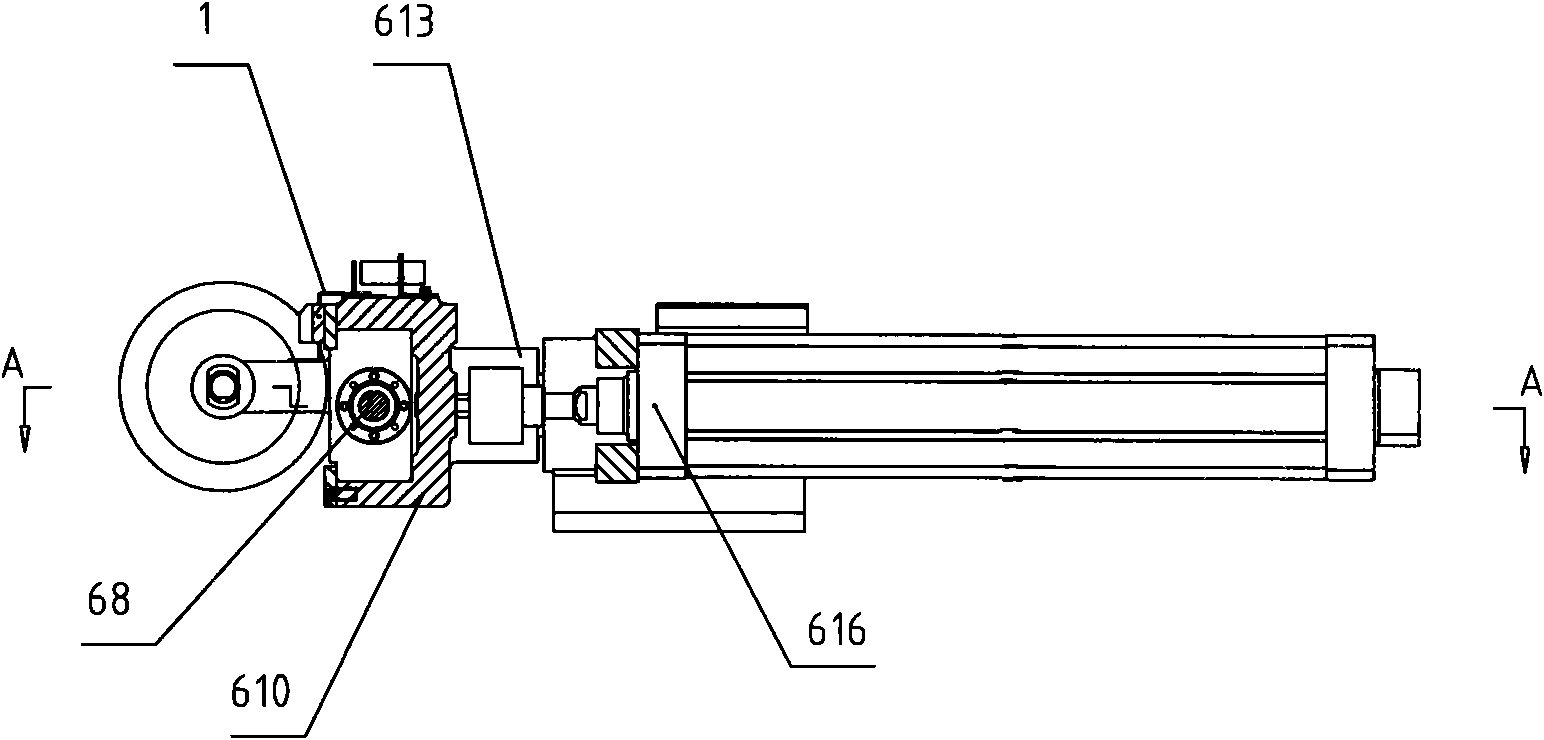

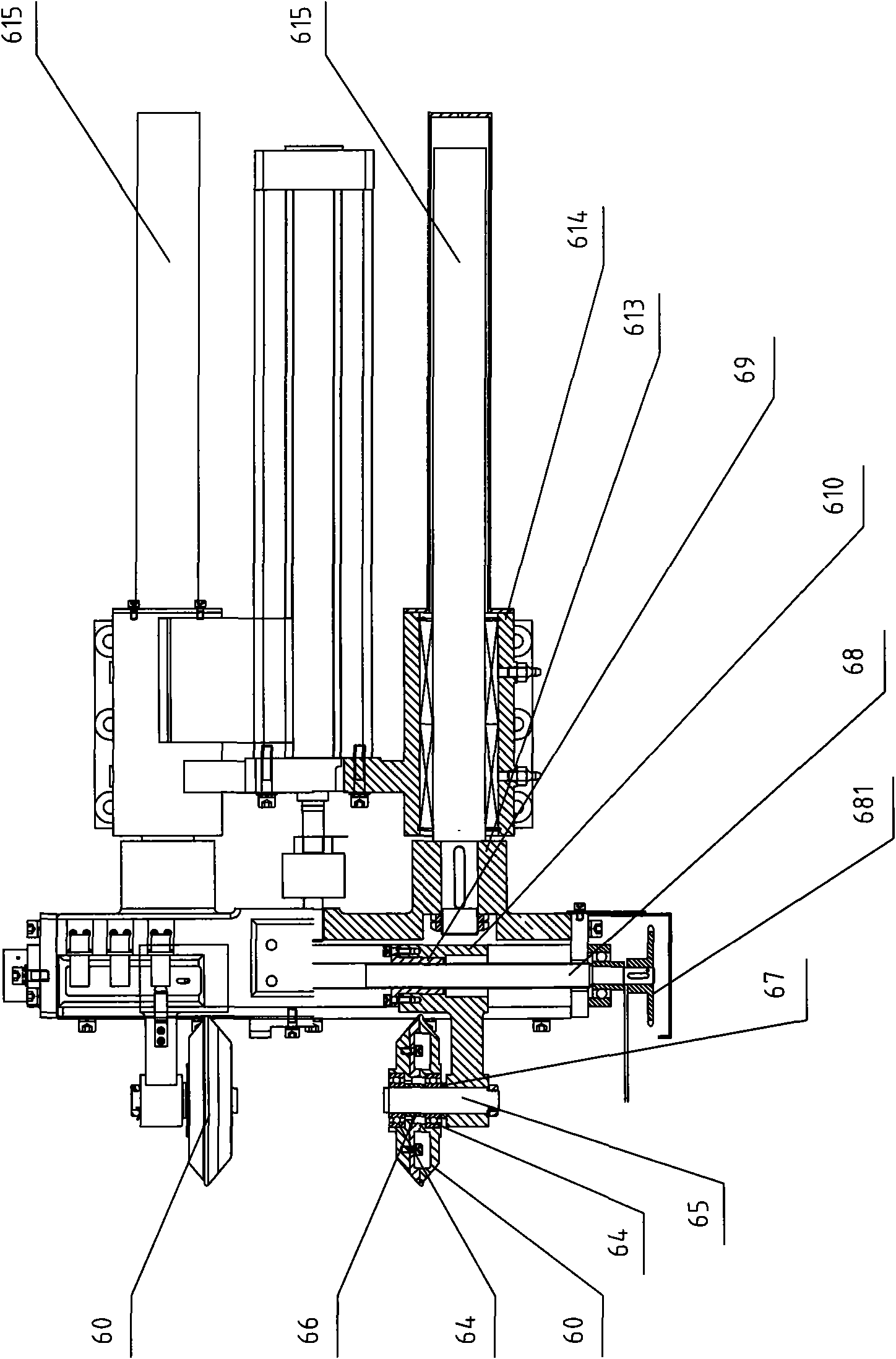

[0051] The second roller device 6 has two sets of No. 2 rollers 60 at the front end, a No. 2 roller cylinder 616, two sets of No. 2 roller ball splines 615, and a horizontal displacement for driving the No. 2 roller 60. The drive unit.

[0052] The second roller device 6 is installed on the frame 5 through the No. 2 roller frame 614, and the No. 2 roller ball spline 615 and the No. 2 roller cylinder 616 are respectively installed on the No. 2 roller frame 614.

[0053] The front ends of the two sets of No. 2 roller ball splines 615 are symmetrically connected to both ends of the No. 2 roller support 613, and the piston rod of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com