Automatic clicker of cell diaphragm

An automatic punching and battery separator technology, applied in battery pack parts, circuits, electrical components, etc., can solve the problems of low utilization rate of separator paper tape, increased production cost, low production efficiency, etc., and achieves simple structure and economical efficiency. The effect of resources and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Further describe the present invention below in conjunction with embodiment and accompanying drawing thereof.

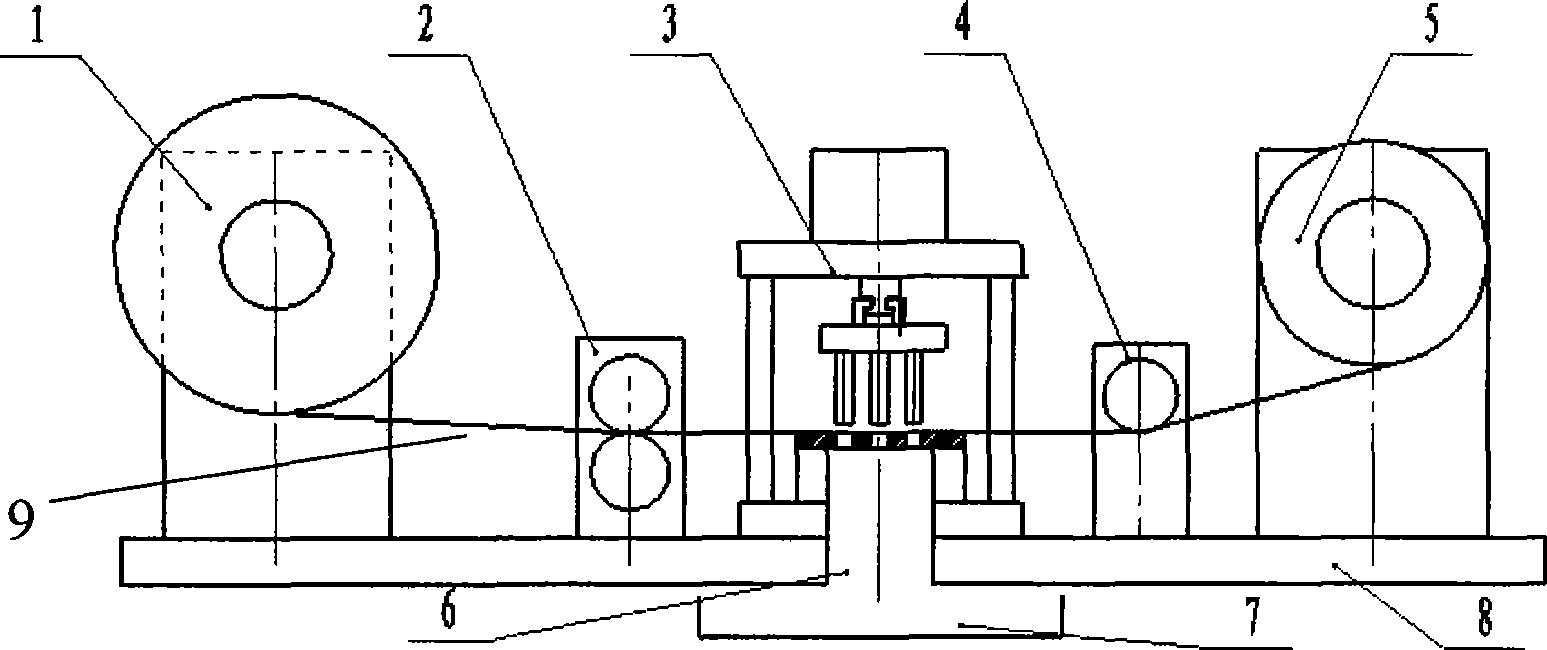

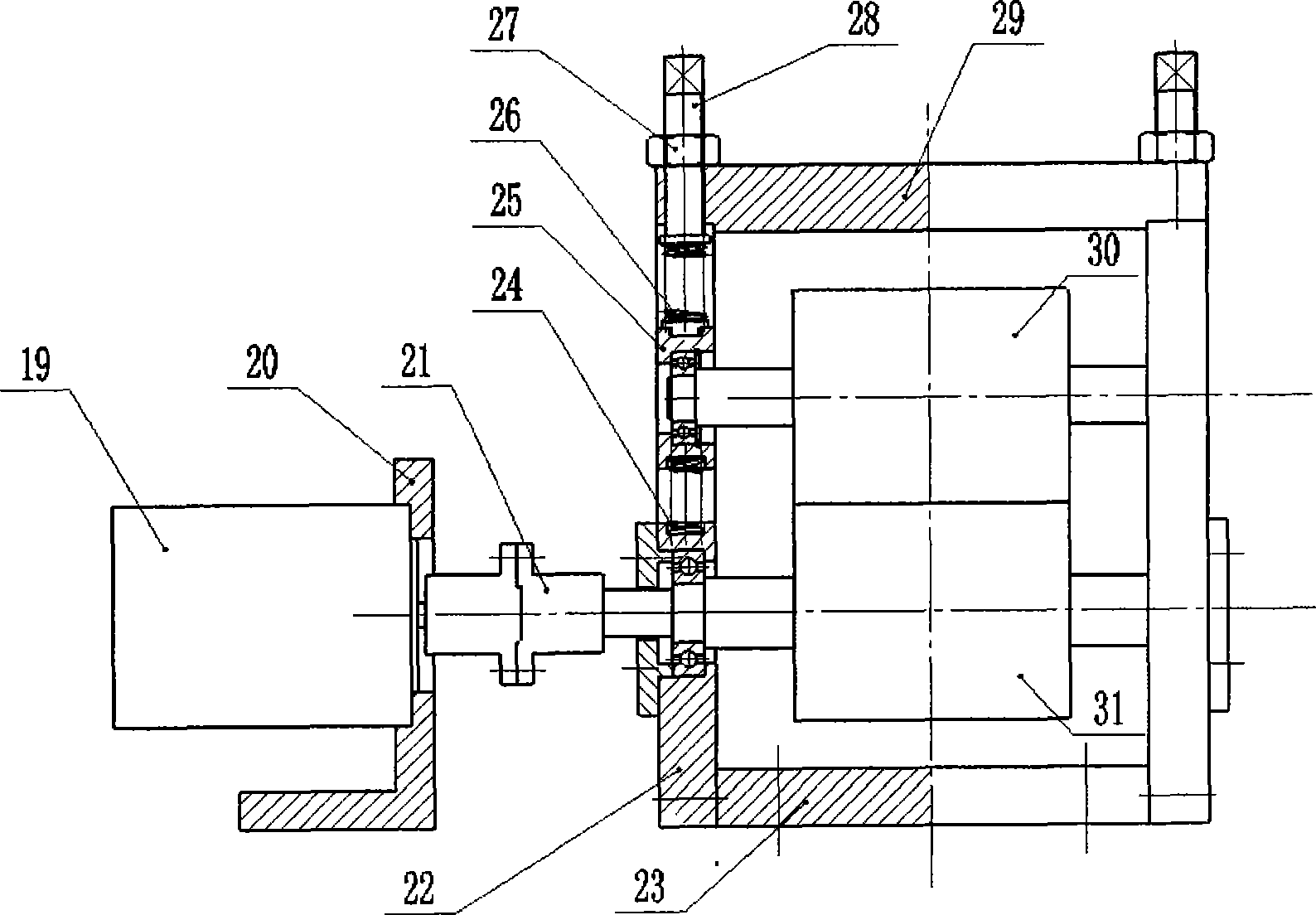

[0019] The battery diaphragm automatic punching machine designed by the present invention (hereinafter referred to as the punching machine, see figure 1 -7), it is characterized in that this blanking machine comprises unwinding mechanism 1, paper feeding mechanism 2, stamping mechanism 3, guiding mechanism 4 and winding mechanism 5 and PLC control system fastened on the large bottom plate 8 in sequence according to the process ;The PLC control system controls the work of the whole machine, especially to realize the coordinated action of "one paper feeding, one stamping".

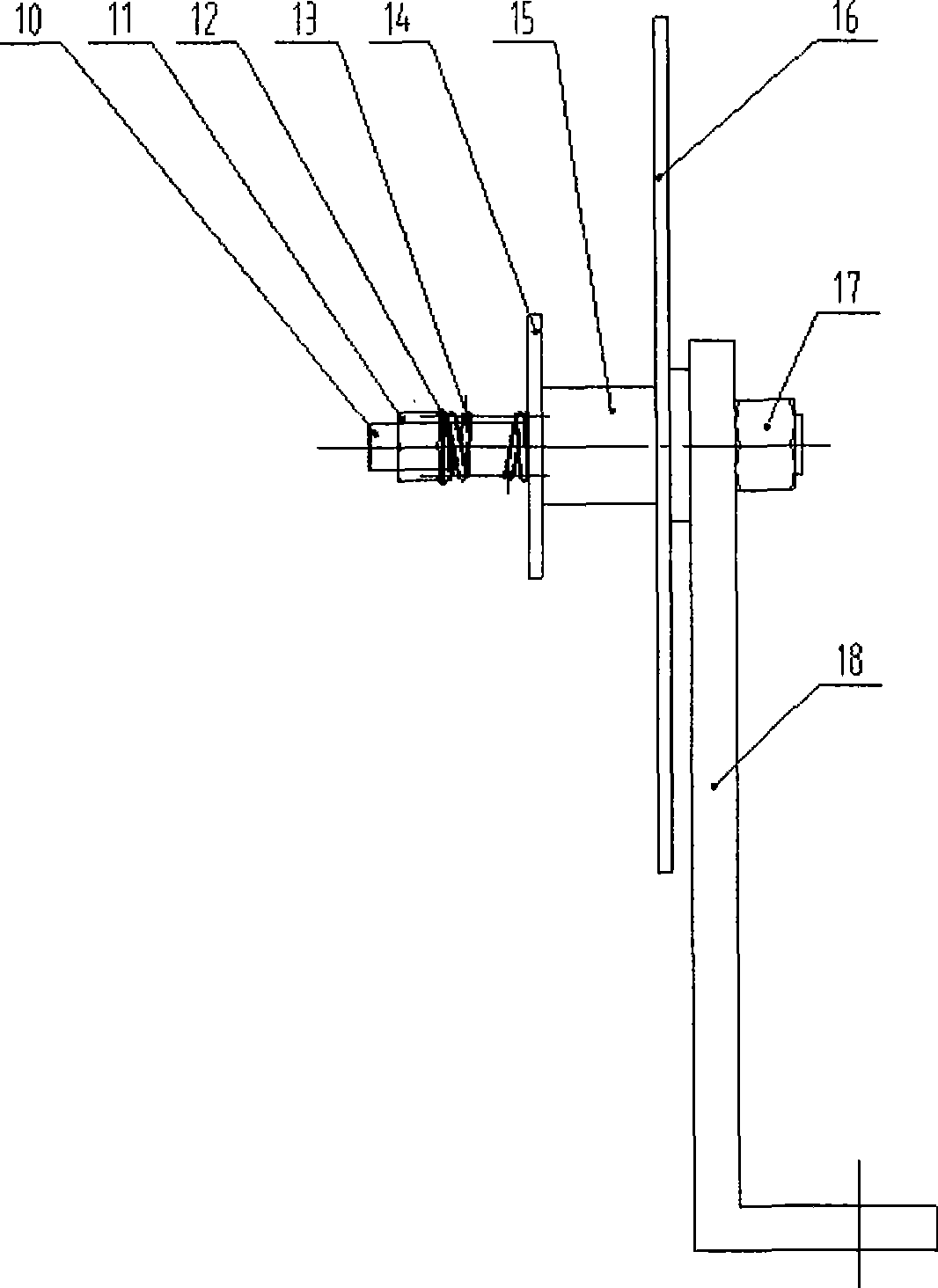

[0020] Described unwinding mechanism 1 (referring to figure 2 ) includes an unwinding shaft 10 and an unwinding bracket 18, the unwinding shaft 10 is fastened on the unwinding bracket 18 by a nut 17, and the unwinding bracket 18 is fastened on the large base plate 8; the unwinding shaft 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com