Comprehensive performance testing platform for planetary roller screw

A comprehensive performance testing, planetary roller technology, applied in the testing of mechanical components, the testing of machine/structural components, measuring devices, etc., can solve the problem of no planetary roller screw, etc., to achieve the effect of automatic measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

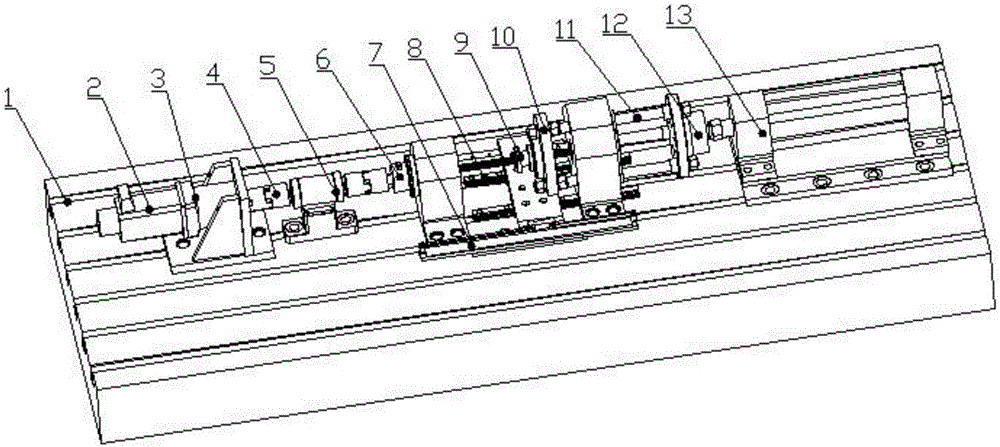

[0009] Specific implementation mode one: combine figure 1 To illustrate this embodiment, a planetary roller screw comprehensive performance test platform described in this embodiment includes a cast iron platform 1, an AC servo motor 2, a planetary reducer 3, an elastic coupling 4, a torque sensor 5, and a rotary encoder 6 , linear guide rail 8, moving platform 10, three bearing columns 11, tension pressure sensor 12 and hydraulic cylinder 13, AC servo motor 2, planetary reducer 3, elastic coupling 4, torque sensor 5, rotary encoder 6, dynamic The platform 10, the tension sensor 12, and the hydraulic cylinder 13 are arranged on the upper surface of the cast iron platform 1 from left to right. The AC servo motor 2 is connected to the planetary speed controller 3, and the planetary speed controller 3 is connected to the torque sensor 5 through the elastic coupling 4. connection, the torque sensor 5 is connected with the rotary encoder 6, the rotary encoder 6 is connected with on...

specific Embodiment approach 2

[0011] Specific implementation mode two: combination figure 1 Describe this embodiment, a planetary roller screw comprehensive performance test platform described in this embodiment also includes a grating scale 7, the grating scale 7 is arranged on the upper surface of the cast iron platform 1, and the grating scale 7 is located on one side of the moving platform 10 . The grating ruler 7 can measure the motion parameters of the moving platform 10 to determine parameters such as the positioning accuracy of the planetary roller screw. Other components and connections are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com