Reciprocating compressor

A compressor and reciprocating technology, applied in the direction of liquid variable displacement machinery, mechanical equipment, machines/engines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

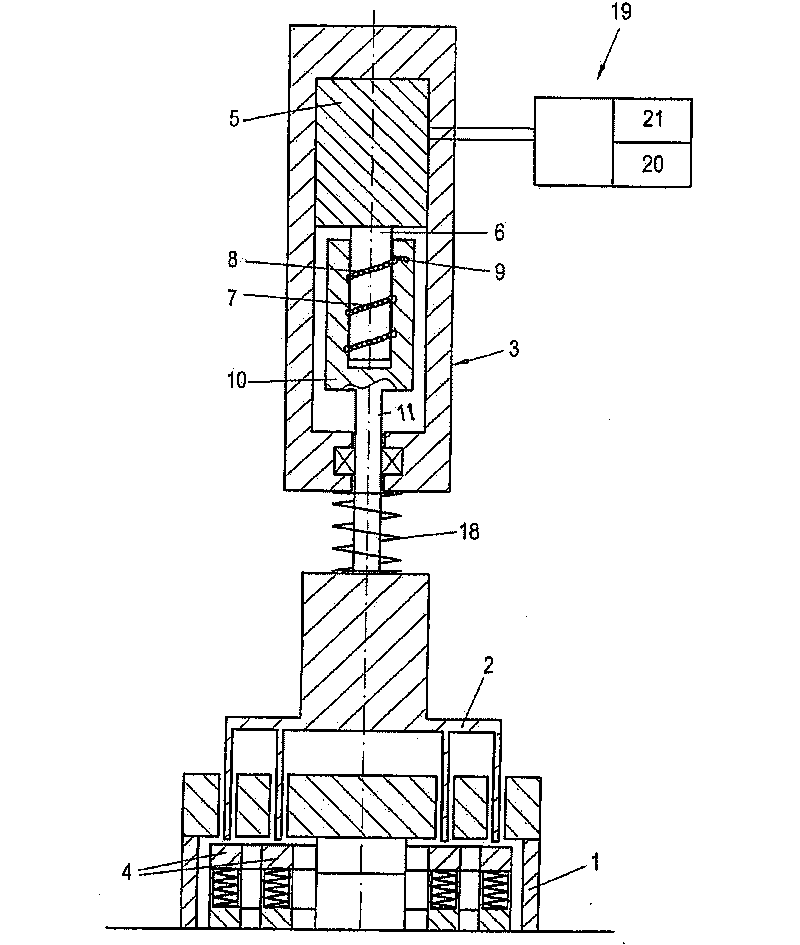

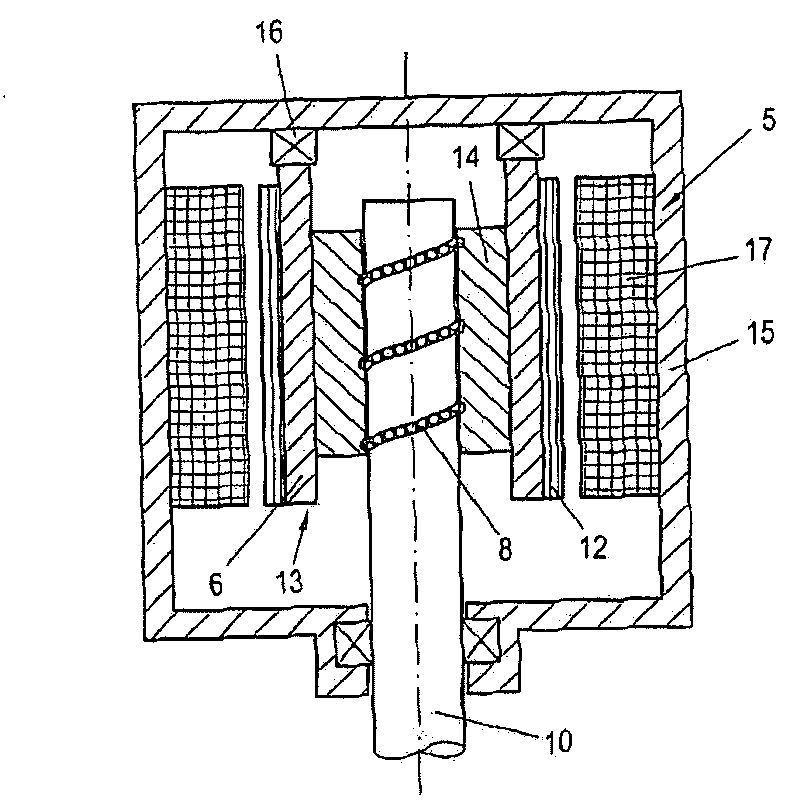

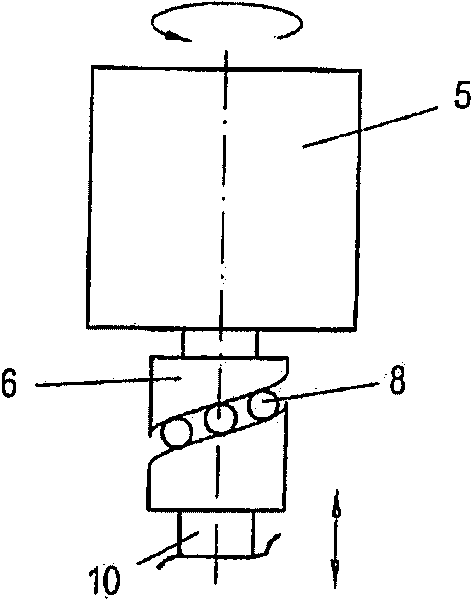

[0019] according to figure 1 , a reciprocating compressor (not further shown in more detail) comprising a valve unloader 2 provided on an automatically acting suction valve 1 of the compressor, said valve unloader being electrically controlled during a controllable phase of the compressor cycle The means 3 are actuated to keep the two annular sealing elements 4 of the suction valve 1 open. To this end, the actuating device 3 comprises an electric motor 5 as drive means, the driven element 6 of which (shown here as a central shaft) comprises a low-friction rolling element 8 extending obliquely in the direction of rotation. The guide surface 7 (shown here as a helical groove on the peripheral surface), the low-friction rolling element 8 on the other hand interacts with a corresponding guide surface 9 extending in an oblique manner on the non-rotating lifting element 10, said non-rotating A rotating lifting element 10 is connected to the valve unloader 2 .

[0020] As long as t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com