Rugged MEMS Switches

A micro-electromechanical switch, micro-electromechanical technology, applied in circuits, relays, electrical components, etc., can solve problems such as performance degradation and fixation, accelerated contact area wear, failure, etc., to achieve the effect of good stability and high actuation force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

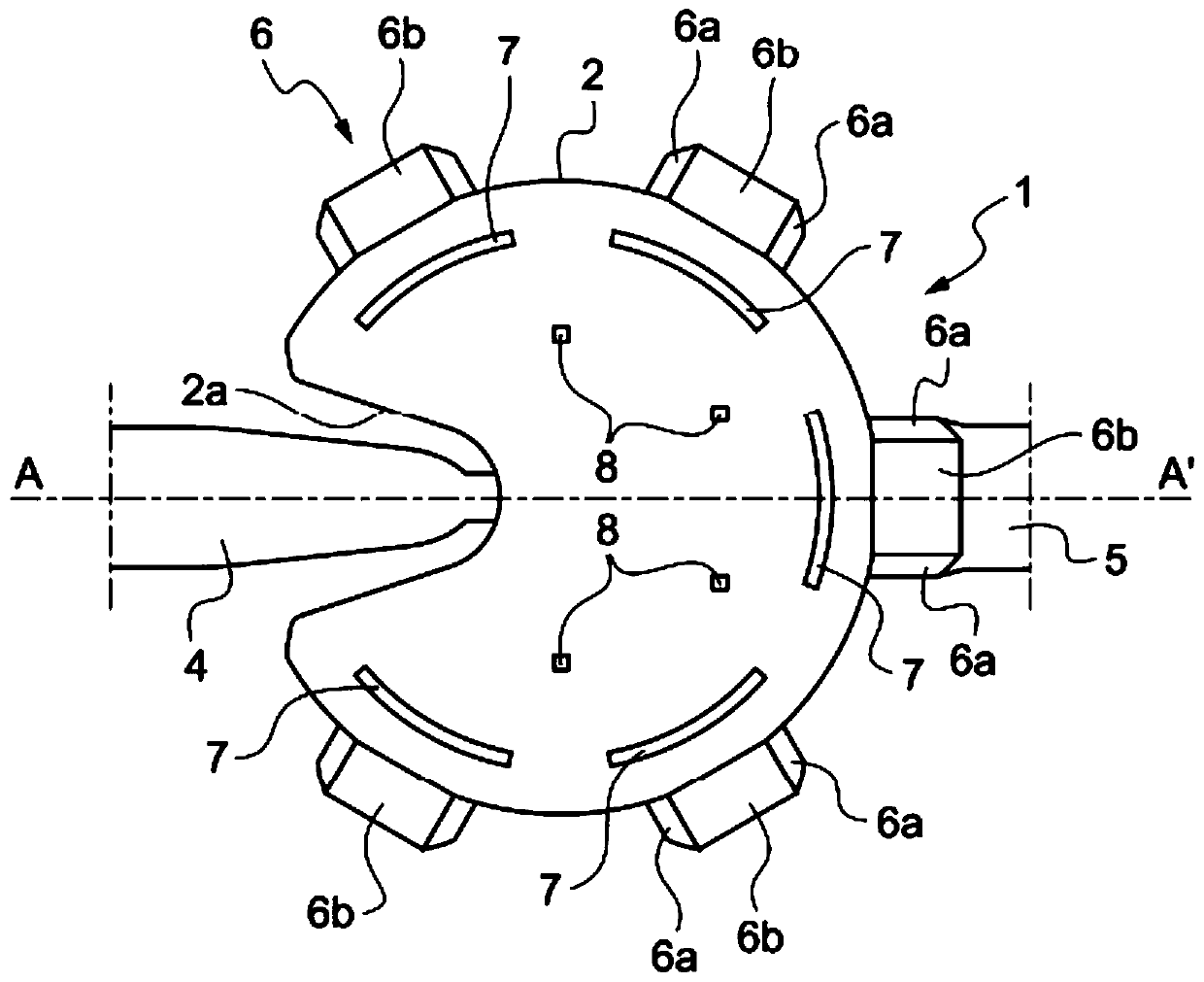

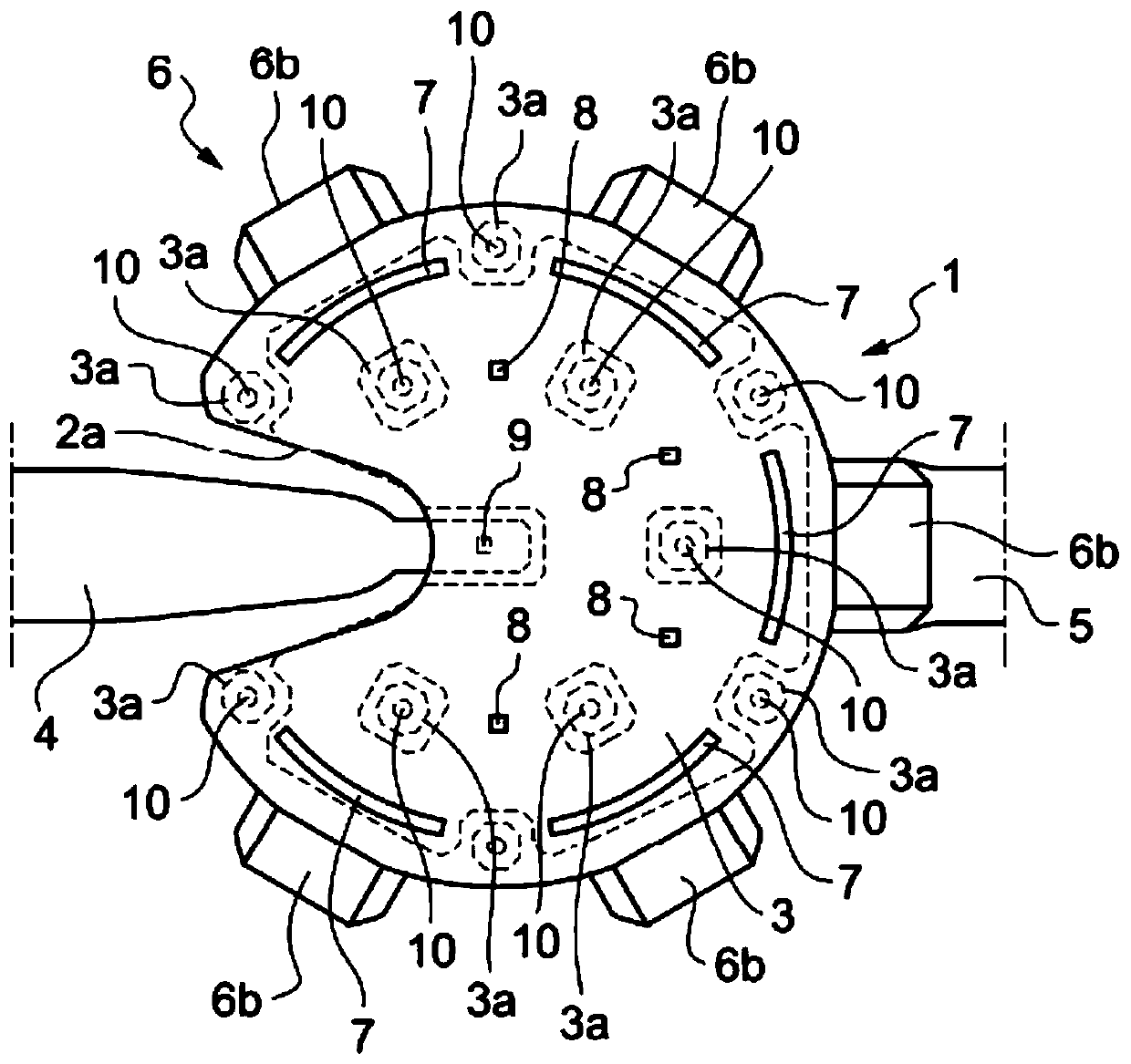

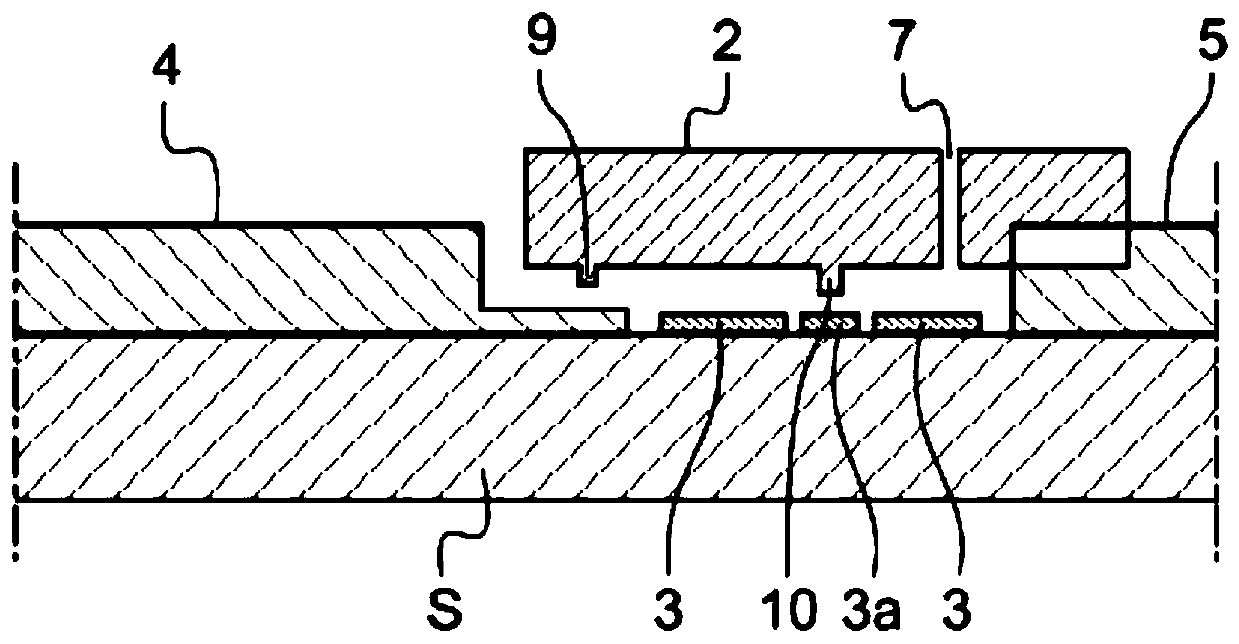

[0054] if reference Figure 1 to Figure 4 , it can be noted that it shows a microelectromechanical (MEMS) switch 1 according to the invention.

[0055] The MEMS switch 1 is formed on a substrate S, and mainly includes a deformable conductive film 2 , an actuation electrode 3 , a signal input line 4 and a signal output line 5 .

[0056] Signal input lines 4 , signal output lines 5 and actuation electrodes are formed on the substrate S. As shown in FIG.

[0057] The deformable conductive membrane 2 is planar, generally circular, with radial openings 2a in the direction of the signal input line 4, so that the periphery of the deformable conductive membrane 2 narrows towards the center. The deformable conductive film 2 is suspended by anchors 6 on the actuation electrodes 3 distributed on its periphery, so as to concentrate the least rigid area of the deformable conductive film 2 at the contact recess, where the signal input lines 4 (to be described below) are arranged At a po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com