Eight-arm mechanical pusher

A pusher and mechanical technology, applied in measurement, wellbore/well parts, earthwork drilling and production, etc., can solve the problems of high manufacturing cost, affecting the accuracy of caliper measurement, and small measurement range, so as to improve reliability and stability Resilience, easy daily maintenance, easy centering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

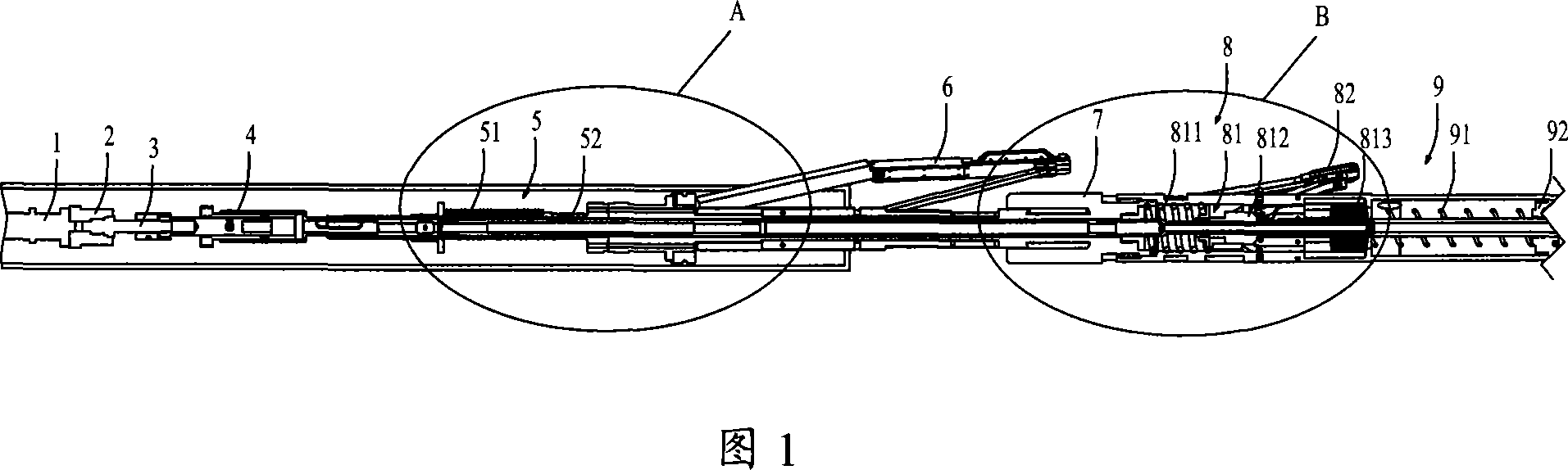

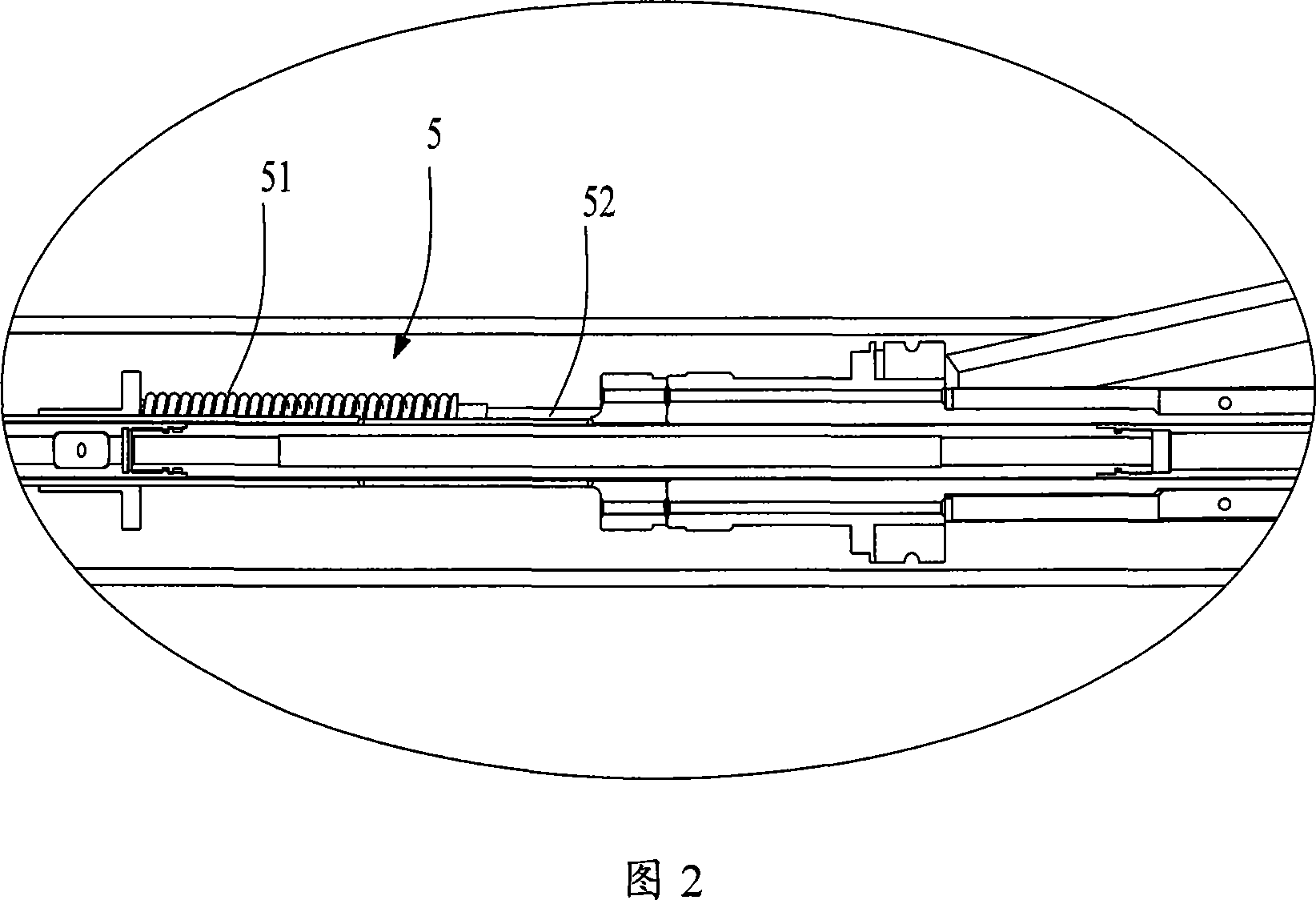

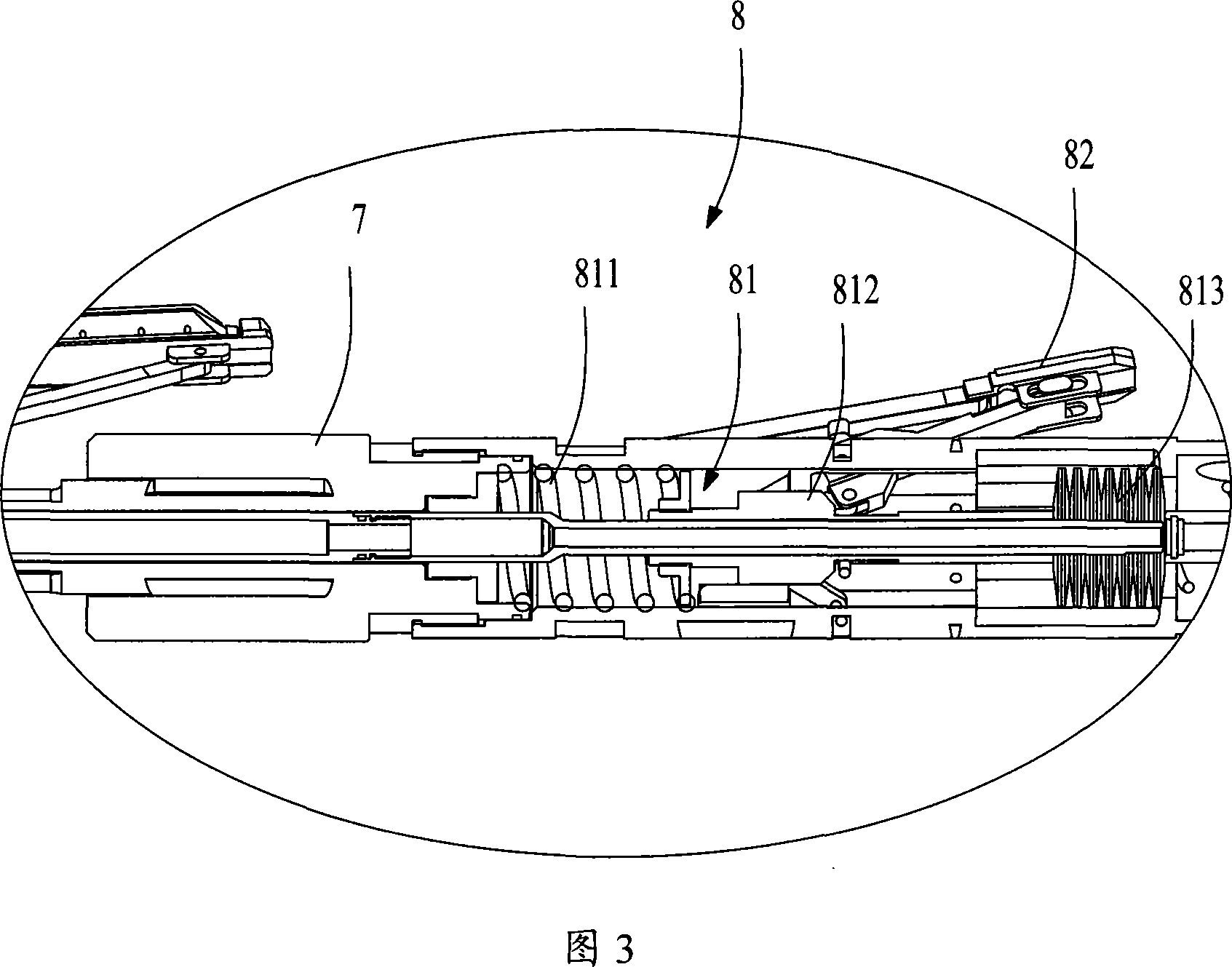

[0016] As shown in Figures 1 and 2, the present invention includes: a motor 1, a clutch 2, a roller screw 3, a transmission part 4, and eight pushing arms 6 arranged in the circumferential direction (only one is shown in Figure 1) ; The motor 1 is connected with the roller screw 3 through the clutch 2, and through the roller screw 3, the circumferential rotation displacement is converted into an axial displacement and then transmitted to the transmission part 4, and the transmission part 4 corresponds to 8 push arms 6 is provided with 8 elastic thrust mechanisms 5 (only one is shown in FIG. 1 ), and the 8 pushing arms 6 are opened or folded under the action of the elastic thrust mechanisms respectively.

[0017] The elastic thrust mechanism 5 includes a push spring 51 and a push rod 52 , one end of the push spring 51 presses against the transmission component 4 , and the other end is elastically connected to the push arm 6 through the push rod 52 . When opened, the motor 1 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com